How to Make Rivets Waterproof?

Table of Contents

In some special cases, users will require rivets to be waterproof. However, not every type of rivet is waterproof. How to make rivets waterproof?

I’ll explain “how to make rivet waterproof” by describing the ways in which rivets are waterproof, the types of rivets that are naturally waterproof, and the ways in which rivet waterproofing can be enhanced.

why do rivets need to be waterproof?

Rivets need to be watertight because while they connect structural components, they can also be a potential conduit for liquids, moisture or gases to penetrate the system. If your business requires rivets to be used in applications where sealing, long-term durability, or electronic safety is critical, rivets that are not waterproof can have the following serious consequences:

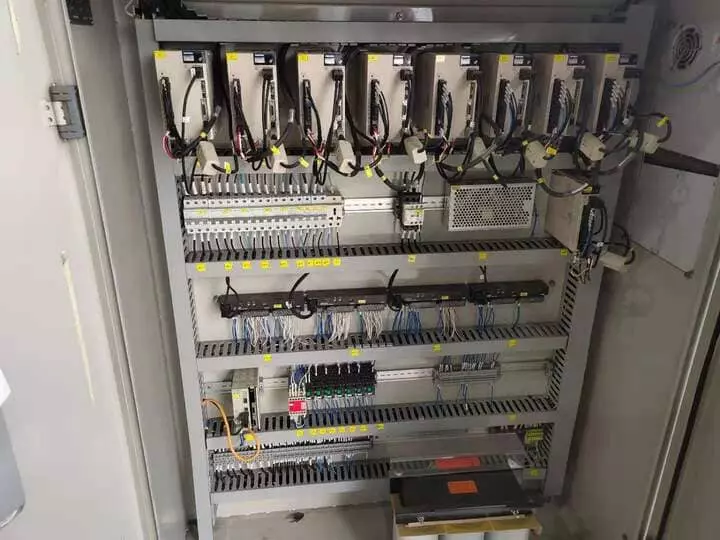

1. Moisture intrusion inside the equipment

Rivet joints that are not tightly sealed can become paths for water vapor penetration, leading to moisture, short-circuiting, or failure of electrical components, control systems, sensors, and so on.

Especially in the structure of electronic control cabinets, outdoor lamps, communication equipment, etc., this small leakage can cause system failure or even safety hazards.

2. Parent material corrosion

Rivet holes that are permeated with water will create a localized humid environment, which may lead to electrochemical corrosion of the parent material over time, especially when the combination of aluminum plate + steel nails is at a higher risk.

Corrosion further expansion, can damage the strength of the connection, shorten the life of the structure.

3. Failure to meet the product IP protection level

In the design of products that need to meet IP65/IP67 dustproof and waterproof rating, rivets as the openings of the shell, if not sealed, will directly lead to the failure of the certification of the whole machine.

The combination of sealed rivets + sealing gaskets is one of the standard ways of IP rating structure design.

4. Entry of water vapor into insulation or thermal barriers

In applications such as refrigeration, HVAC, building curtain walls, etc., water seepage may damage the structure of the insulation layer, reduce the efficiency of energy saving, and harbor mold and mildew.

several ways in which rivets create a waterproof effect

Rivets achieve a watertight effect and are usually realized in several ways. Below are a few of the main ways that rivets create a waterproof effect:

Closed-End Design(Closed end blind rivets)

Mandrel Retention

Flush Expansion Fit (Bulb Ttie Blind Rivets)

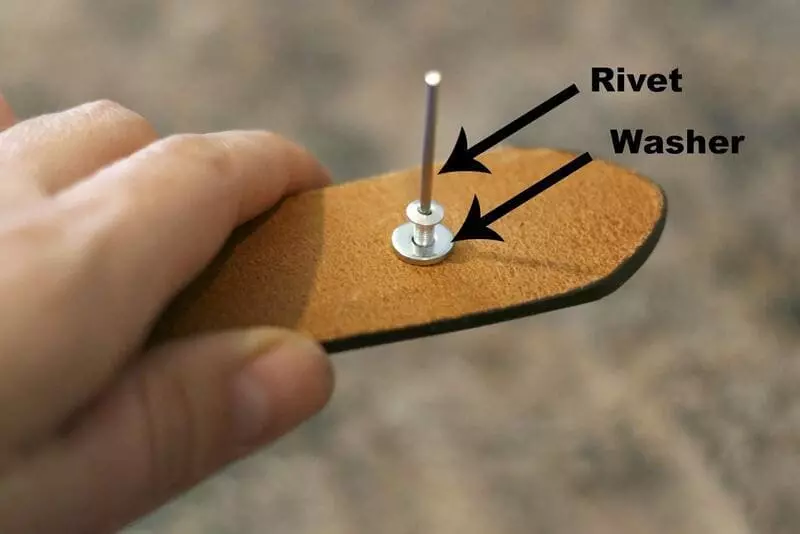

Sealing Washer

- Sealant or Waterproof Coating

Rivet waterproofing does not depend on a single factor, but rather a combination of four elements: “structure + sealing + materials + installation”. Depending on the environment, one or more of these elements should be used to achieve truly effective waterproofing.

Waterproof Rivet Best Practices: Sealed Rivet + Sealing Washer + Sealant + Corrosion Resistant Material

are some types of rivets naturally waterproof?

Among the types of rivets, there do exist rivets that are inherently waterproof. These rivets are naturally designed and selected to prevent the penetration of liquids, gases or water vapor, and can achieve basic waterproofing without the need for additional sealing treatments. Typical types are listed below:

Structural features: the end is closed metal bottom, the core rod will not penetrate or loose, eliminating the through-hole leakage path.

Scope of application: outdoor equipment, electrical boxes, waterproof light housings, machinery shells.

Waterproof ability: with structural grade waterproof ability, suitable for low and medium pressure water vapor environment.

✅ Conclusion: It is the most commonly used and representative self-waterproofing rivets.

Structural features: mandrel and rivet body form an internal lock, residual no gap, tail expansion structure fit strong.

Advantages: high strength + anti-loosening + high tightness.

Scope of application: vehicles, outdoor boxes, mechanical frames and other load-bearing + sealing and heavy structure.

✅ Conclusion: Although not designed for waterproof, its locking structure has high waterproof stability.

Structural features: Rivet cap edge embedded rubber sealing ring, or the whole package of rubber encapsulation.

Scope of application: high protection level IP67 above the electronic shell, outdoor equipment.

Advantage: factory that is waterproof design, installation that is sealed.

✅ Conclusion: special custom rivets, suitable for high-volume standardized use, reduce construction complexity.

Which coatings enhance the water resistance of rivets?

Among the measures to enhance the water resistance of rivets, the choice of surface coatings is one of the key factors. They not only affect whether the structure is resistant to water and corrosion, but also determine the durability of the joint’s seal in wet and hot, high salt and high pressure environments. The following are the material and coating combinations that best enhance the water resistance of rivets:

- Anodizing – For Aluminum Rivets

- Zinc Plating- for carbon steel rivets

- Passivation

- Epoxy Coating or PVDF Coating

- Nickel / Tin Plating

Recommended Material & Coating Combinations for Waterproof Rivets

| Material/Coating Combination | Waterproof Performance | Recommended Application Scenarios |

|---|---|---|

| Stainless Steel + Passivation | ★★★★★ | Outdoor equipment, electrical enclosures, marine hardware |

| Aluminum Alloy + Anodizing | ★★★★☆ | Curtain walls, HVAC systems, traffic signage |

| Carbon Steel + Zinc Plating + Butyl Washer | ★★★☆☆ | General industrial use, piping systems, control cabinets |

| Copper/Brass + Nickel Plating | ★★★★☆ | Moisture-resistant electronics, grounding terminals, PCBs |

should you use sealants or washers with rivets for waterproofing?

The use of sealants or sealing gaskets in waterproofing applications can significantly improve the overall waterproofing of a rivet. While some rivet types (e.g. closed end rivets) are inherently watertight, the rivet construction alone is often not sufficient to ensure a consistent seal over time in variable or extreme environments.

Advantages of using sealants or gaskets

1. Seal microgaps to improve seal integrity

- There are often micro-seams or uneven surfaces between the rivet cap rim and the parent material;

- Rubber or silicone gaskets flexibly fill gaps and prevent water vapor penetration;

- Sealants can penetrate deep into hairline gaps to form a complete sealing film.

2. Resistance to thermal expansion and contraction and vibration stresses

- Prolonged exposure to the outdoors or temperature differences, thermal expansion and contraction of materials can lead to loosening or cracking of the sealing structure;

- Sealing gasket and elastic gel can absorb the stress changes and keep the joint sealing without deformation.

3. Enhanced weathering and corrosion resistance

- Sealant can isolate moisture, salt spray, oil and other corrosive media;

- Prevent the rivets or parent material orifice due to corrosion to form leakage points.

4. Meet higher IP protection level requirements

- In high protection class designs such as IP65/IP66/IP67, the rivet body alone is often not sufficient;

- The addition of gaskets and sealants is necessary to pass the protection level test.

Sealants and sealing gaskets are not “optional”, but are key components in a watertight design to ensure reliability and durability. Sealing accessories are recommended as standard for any riveted connection in electrical, outdoor, or wet environments.

What standards apply to waterproof rivet construction?

IP protection rating standard (Ingress Protection Rating, IEC 60529)

Scope of application: electronics, electrical cabinet, industrial housing, control panel

Role of rivets: as a structural connection must meet the protection rating of the overall housing

Common target ratings:

- IP65: dustproof + resistant to low pressure water jets

- IP66: dustproof + resistant to strong water jets

- IP67: Dust protection + short-term immersion (water depth 1m, 30 minutes)

- IP68: Dustproof + Long-term underwater operation (according to customer specifications)

🔧 Note: Closed end rivets + sealing washers + sealant are typical configurations to achieve IP65/67.

Wholesale Waterproof rivets from Rivmate

If you are looking for reliable waterproof rivets for your project or business, then you can rest assured that you can talk to Rivmate.

Rivmate – Leading Rivet Manufacturer and Supplier in the World.

Whether it’s closed end blind rivets, waterproof bulb tite blind rivets or structural interlock blind rivets, you can get any size waterproof rivets at Rivmate.

Share:

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met