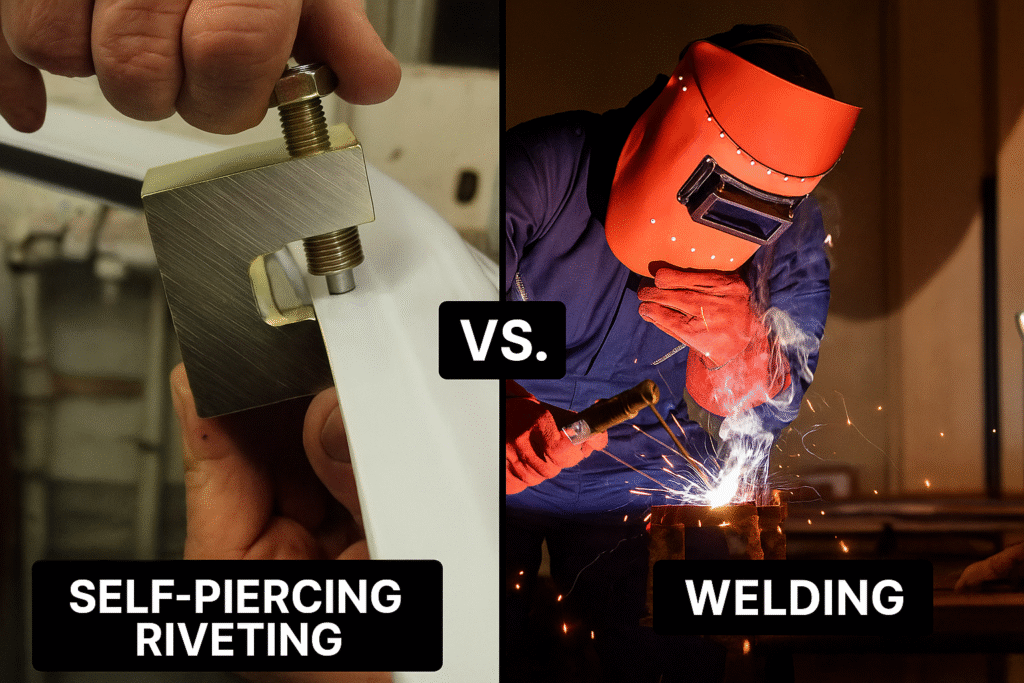

What are the Key Advantages of Using Self-Piercing Rivets Compared to Traditional Rivets or Welding?

Table of Contents

In modern manufacturing, the trend of material diversity is becoming increasingly evident. Lightweight structures have led to the widespread use of aluminum, composite materials, and galvanized steel. However, these materials are often not suitable for traditional welding or ordinary riveting processes. This results in problems such as insufficient strength and damage to the heat-affected zone during assembly. Therefore, exploring more reliable and efficient connection methods has become an industry consensus.

This is precisely the background for the rapid rise of the Self-Piercing Rivets (SPR) technology. It does not require pre-drilling and does not rely on heat energy, enabling strong connections between different materials. Many automobile, aviation, and rail transportation manufacturers have listed it as their preferred process. So, what are the advantages of using self-piercing rivets compared to traditional riveting and welding? This article will deeply analyze why SPR technology has stood out in multiple manufacturing scenarios.

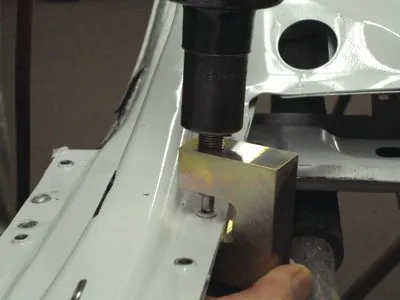

Self-piercing riveting (SPR) is an advanced mechanical connection process. Its most significant feature is that it does not require pre-drilling. The rivet, under the action of hydraulic or servo pressure, directly penetrates the upper layer material and expands and forms in the lower layer material, ultimately achieving a reliable mechanical locking.

The process flow can be summarized into four steps: Compression → Penetration of the upper layer → Expansion → Locking. The entire process requires only one operation, which is highly efficient and stable.

Compared with traditional techniques, the differences are quite obvious:

- Traditional Rivets: They require pre-drilling and usually require double-sided operation. The efficiency is low and it increases the process cost.

- Welding: It belongs to a thermal processing method and will create a heat affected zone (HAZ), which may reduce the material strength and corrosion resistance. Especially for lightweight materials such as aluminum and galvanized steel, the welding effect is not ideal.

- Self-Piercing Riveting (SPR): It can be completed in a single operation without pre-treatment and will not generate a heat affected zone. It can maintain connection strength and consistency in different material combinations.

For this reason, SPR has become a crucial connection technology in industries such as automotive, aviation and home appliance manufacturing, and is widely used to replace traditional riveting and welding processes.

Advantages of Self-Piercing Riveting over Traditional Riveting

In modern manufacturing, efficiency and consistency are the core competitiveness. Self-piercing riveting (SPR) outperforms traditional riveting and is particularly suitable for industries that have higher requirements for production cycle and connection quality.

a. No Pre-Drilling Required

The SPR rivets can be directly pressed into the material. This eliminates the need for drilling steps, reducing process time and tool wear. Depending on the actual application, it can shorten the assembly time by 20% to 30%.

b. Single-Sided Access

Traditional riveting usually requires a two-sided cooperation, while SPR can be completed with just one side. It is particularly suitable for body closed cavities or complex structural components, significantly enhancing the design flexibility.

c. Faster Assembly Speed

The SPR equipment can be integrated with automated production lines, and the single-point riveting cycle usually lasts around 1 second. It is highly suitable for mass production, such as in the manufacturing of automotive body panels.

d. Consistent Quality

The SPR process is highly standardized and does not rely on manual drilling or precise riveting. The connection results are more stable and the defect rate is significantly reduced.

e. Weight Reduction

SPR rivets are usually lightweight and support multi-material connections. For the automotive and aerospace industries, this means that while maintaining strength, they can further meet the requirements of lightweighting and energy conservation.

Advantages of Self-Piercing Riveting over Welding

Self-piercing riveting (SPR) offers a more flexible and reliable solution. Its main advantages are as follows:

Suitable for joining of dissimilar materials

SPR can easily achieve connections of aluminum + steel, galvanized steel + composite materials, etc. In these scenarios, welding is difficult and often results in insufficient strength or unstable performance.

No Heat Affected Zone (HAZ)

Since no heating is required, SPR avoids the problems of metal structure changes and strength reduction. For galvanized steel, it can also maintain the integrity of the anti-corrosion coating and extend the service life of the material.

Eco-Friendly & Safer Process

The SPR process features no sparks, no gases, and no welding wires, making it safer to operate. Moreover, its energy consumption is lower than that of the welding process, aligning with the manufacturing industry’s goals of carbon reduction and sustainable development.

Better Finish & Consistency

No welding slag, splashing or burn marks will be produced. The connection points will be smoother and more aesthetically pleasing, with higher assembly consistency, reducing the need for subsequent grinding and surface treatment.

Improved Fatigue Resistance

The welding points are prone to cracking under long-term vibration or impact conditions. The SPR connection, however, demonstrates better fatigue resistance and is more suitable for dynamic working environments such as those in automobiles and aviation.

Comparison Table: Self-Piercing Riveting vs Welding

| Comparison Dimension | Self-Piercing Riveting (SPR) | Welding |

|---|---|---|

| Dissimilar Material Joining | Can join aluminum, steel, and composites; highly versatile | Limited in most cases; aluminum + steel combinations are difficult |

| Heat Affected Zone (HAZ) | No heat effect, no material deformation or strength reduction | Heat affected zone present; may cause structural changes and strength loss |

| Coating Protection | Preserves coatings, offering better corrosion resistance | Coatings often damaged, increasing corrosion risk |

| Eco-Friendliness & Safety | No sparks, low energy consumption, safer; aligns with carbon reduction goals | High energy consumption, sparks, fumes, and safety risks |

| Appearance & Consistency | Clean joints, no spatter, higher quality consistency | Requires post-processing, appearance may be uneven |

| Fatigue Performance | Excellent fatigue resistance, suitable for vibration environments | Prone to cracks, poorer long-term durability |

Limitations of SPR

Although self-tapping riveting (SPR) is widely used in industries such as automobiles, aviation, and home appliances, its application still has certain limitations. Understanding these limitations can help enterprises make more rational and cost-effective decisions when choosing processes.

High Initial Investment

SPR requires dedicated press-bolt joining equipment, usually a hydraulic or servo-driven system. Compared with traditional riveting or welding, the equipment cost is higher and the initial investment pressure is greater. Small and medium-sized manufacturers need to assess the payback period when introducing this technology.

Not Suitable for Very Thick or Ultra-Hard Materials

The penetration and expansion depth of SPR rivets are limited. For materials with a thickness or hardness exceeding a certain level, reliable locking may not be achievable. In such cases, welding or mechanical fasteners are still typically required.

Permanent Joint

Once the SPR connector is formed, it is difficult to disassemble without damaging the material. Therefore, it is not suitable for products that require frequent assembly and maintenance. For example, in some electrical equipment or replaceable components, threaded fasteners are still a better choice.

To sum up, self-tapping riveting is not a universal solution. It excels in lightweighting, multi-material applications, and batch production, but enterprises still need to consider factors such as material properties, production scale, and maintenance requirements, and conduct a comprehensive assessment before implementing it.

Applications in Industry

Self-tapping riveting (SPR) has been widely adopted by multiple industries. It addresses the limitations of traditional welding and riveting in terms of lightweighting, multi-materiality, and corrosion resistance. Here are some typical application scenarios:

- Automotive Manufacturing

SPR is widely used in aluminum body panels and lightweight frames. Car manufacturers such as Tesla and Jaguar Land Rover all adopt SPR to achieve multi-material connections of aluminum and steel, and to enhance the strength and durability of the vehicle body. - Aerospace

SPR can connect aluminum alloys with composite materials. Such combinations are particularly common in aircraft skins, hatches and structural components. Compared with welding, SPR avoids thermal influence and enhances fatigue life.

- Appliances and Construction

In household appliances such as refrigerators and washing machines, SPR can efficiently connect thin sheet metals with coated steel plates while maintaining the surface integrity. The construction industry also employs SPR in areas like curtain walls and metal roofing to enhance construction speed and reliability.

Application Case Comparison Table

| Industry | Key Challenges | SPR Solutions |

|---|---|---|

| Automotive Manufacturing | Difficulties in aluminum + steel hybrid joining; welding easily damages protective coatings | SPR enables high-strength joining without welding, maintaining corrosion resistance |

| Aerospace | Aluminum alloy + composite materials cannot be efficiently welded; high fatigue life requirements | SPR provides stable mechanical locking, enhancing fatigue performance |

| Appliances & Construction | Thin sheet metals and coated steels are prone to deformation or corrosion; high efficiency required | SPR avoids heat effects, preserves coating integrity, and improves production efficiency |

Rivmate Expertise & Solutions

In the context of the continuous expansion of self-tapping riveting (SPR) applications, Rivmate has emerged as a reliable partner for manufacturing enterprises, thanks to its comprehensive product line and technical support. Its advantages are not only reflected in the performance of the rivets themselves, but also in its systematic process integration capabilities.

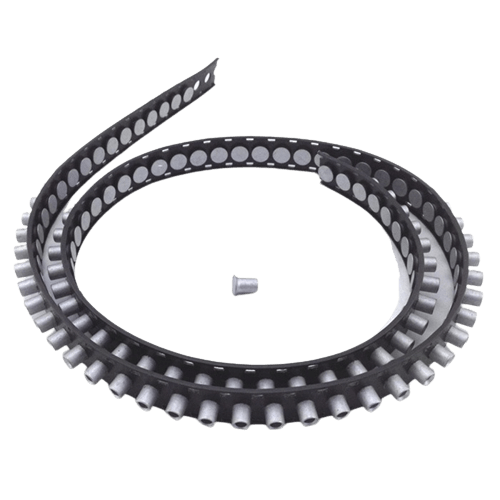

Main features of Rivmate self-tapping rivets:

- Multiple material options: Offers steel, stainless steel, and aluminum alloy rivets, meeting the requirements for different material combinations and strength.

- Wide range of Grip Options: Suitable for connecting plates of various thicknesses and layers, ensuring process flexibility.

- Compliant with ISO and DIN international standards: Ensures product consistency and reliability, suitable for cross-border supply chain applications.

The value-added services that Rivmate can offer to customers:

- Process Consultation and Selection Support: Based on material properties and structural requirements, assist customers in choosing the optimal riveting solution.

- SPR Equipment Compatibility Solutions: Ensure that the rivets are compatible with existing press riveting equipment, avoiding redundant investment.

- Customized Riveting Services: For special applications, support the development of non-standard rivets and small-scale trial production to accelerate product verification and introduction.

By integrating standardized products with professional technical support, Rivmate not only offers rivets, but also provides system solutions. This enables customers to gain long-term competitive advantages in areas such as improving assembly efficiency, ensuring connection quality, and reducing maintenance costs.

FAQ

Q1: Is SPR stronger than welding?

It is not solely determined by the “strength” single indicator. SPR outperforms welding in terms of intermetallic bonding, fatigue performance, and appearance consistency. Especially in the combination of aluminum and galvanized steel, SPR is more reliable than welding. However, in some thick plate steel structures, welding still has a higher load-bearing capacity.

Q2: Can SPR completely replace traditional riveting?

This is not the case. SPR is suitable for automated, large-scale, and multi-material application scenarios. Traditional riveting still has advantages under the conditions of low cost, small batch production, and disassemblability requirements. Therefore, the two are complementary in the manufacturing industry, rather than completely substituting for each other.

Q3: Can SPR be applied to composite materials?

Sure. SPR is widely used in the structures of aluminum alloys + composite materials, such as aircraft skins and car bodies. It can prevent the composite materials from being damaged during high-temperature welding. However, the appropriate type of rivets and pressure parameters need to be selected based on the laminated structure of the composite materials.

Q4: Can Rivmate provide a selection chart for SPR rivets?

Sure. Rivmate offers a standardized bolt selection guide, covering aspects such as material, Grip Range, and application scenarios. Customers can also receive customized selection support to ensure that the riveting solution is highly compatible with the production process.

Get Your Rivmate SPR Selection Guide Today

Self-Piercing riveting (SPR) has become a cutting-edge joining technology in modern manufacturing due to its efficient assembly, ability to connect different materials, environmental friendliness and low energy consumption, as well as high consistency. Especially in industries such as automobiles, aviation, home appliances and construction, SPR demonstrates advantages that traditional riveting and welding cannot match. With the development of lightweighting and multi-material trends, the application scope of SPR is expected to continue to expand.

Looking for the best self-piercing riveting solution for your project? Contact Rivmate immediately to obtain our professional self-piercing rivet selection guide and communicate with our technical team. Whether it’s material assessment, equipment compatibility, or customized rivet design, Rivmate can provide you with efficient, reliable, and internationally compliant solutions.

📩 Contact Rivmate immediately to make your manufacturing process lighter, faster and stronger.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met