What Is Self-Piercing Riveting Used For?

Table of Contents

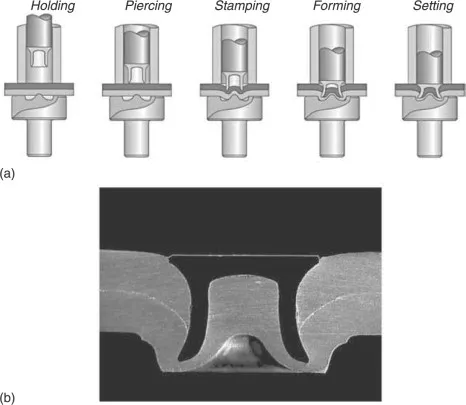

What is self-piercing riveting used for? This is the most frequently raised question by manufacturing engineers and designers when dealing with the demand for new material connections. With the widespread application of lightweight design and composite materials, traditional welding and riveting processes are facing challenges. The use of high-strength steel, aluminum alloys, and coated sheets has led to the occurrence of heat affected zones during welding, and traditional rivets are unable to meet the dual requirements of efficiency and strength.

In this context, Self-Piercing Riveting (SPR) has become the preferred process in an increasing number of industries. It does not require pre-drilling and can efficiently connect different materials, and is highly suitable for automated production. This article will systematically elaborate on the typical application fields of SPR and explain why it has rapidly gained popularity in industries such as automotive, aerospace, and construction.

Why SPR Is Valuable Across Industries?

The reason why self-piercing riveting (abbreviated as SPR) has been widely used in various industries such as automobiles, aviation, and construction is due to its unique technical characteristics. These characteristics not only address the shortcomings of traditional welding and riveting, but also provide new possibilities for lightweighting and the use of unconventional materials.

a. Single-Sided Operation

The SPR only needs to be operated on one side of the workpiece. Even if the back side cannot be accessed, assembly can still be completed. This feature is particularly important in automotive body and sealed structures.

b. No Pre-Drilling Required

Unlike traditional riveting, SPR can directly penetrate the upper layer material under high pressure. This eliminates the drilling process and enhances production efficiency. According to industry research, omitting the drilling step can increase the assembly cycle time by 20%-30%.

c. Ideal for Multi-Material Joints

SPR can achieve reliable connections in combinations such as aluminum + steel, galvanized steel + composite materials. Traditional welding is often limited in these scenarios, but SPR can ensure strength and durability.

d. No Heat Affected Zone (HAZ)

SPR is a cold processing technique that does not alter the mechanical properties of the material nor damage the surface coating. Compared to welding, it can effectively prevent material deformation and the decline in fatigue performance.

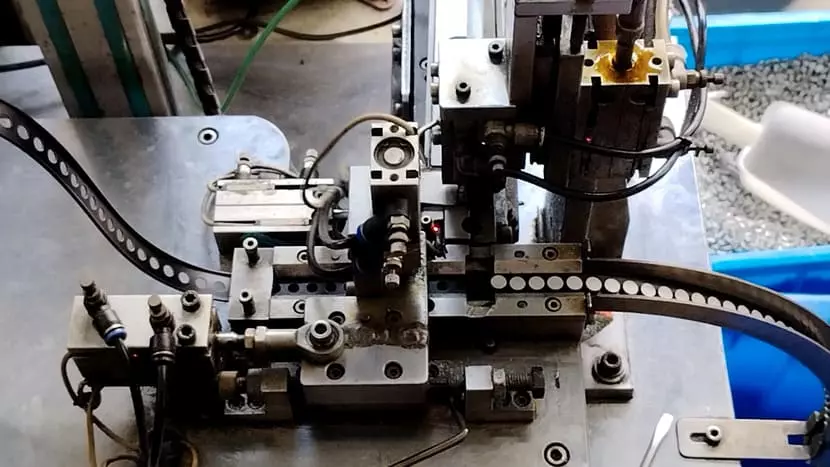

e. Automation Friendly

SPR is highly suitable for robots and automated production lines. It has high consistency and strong repeatability, which can meet the requirements of mass production. Therefore, SPR has become one of the standard processes in automotive lightweight production lines.

1. Automotive Industry

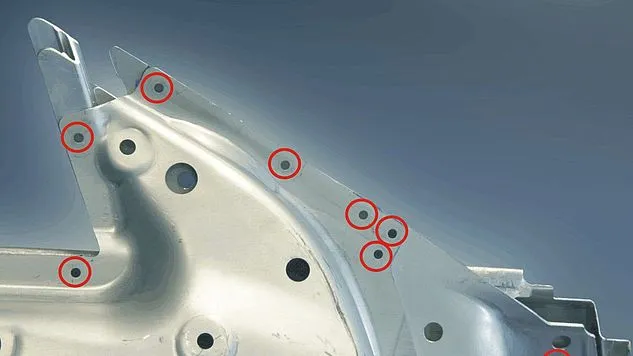

Self-piercing riveting (SPR) is the most widely used in the automotive industry, especially in aluminum bodywork and lightweight structures.

1.1. The Most Applicable Scenario

- Aluminum body and panels.

- Lightweight frame and suspension components.

- Aluminum + steel hybrid material body structure.

1.2. Resolution of Pain Points

- Welding aluminum alloy is difficult and it is prone to generate heat affected zone (HAZ), which leads to a decline in material performance.

- Traditional spot welding has poor adaptability to aluminum and galvanized steel, and the quality of the weld points is unstable.

- SPR can achieve reliable mechanical locking in the multi-layer structure of aluminum + steel, avoiding welding defects.

1.3. Industry Cases

- The body of Tesla Model 3 is connected using SPR.

- Jaguar Land Rover extensively uses SPR in its all-aluminum body structure.

- BMW combines SPR with adhesives in its lightweight frame to achieve high strength and durability.

1.4. Value Realization

- Lightweighting: Reduces vehicle weight, enhances fuel efficiency and extends electric vehicle range.

- Energy conservation and emission reduction: Complies with the low-carbon trend in the global automotive industry.

- Production efficiency improvement: SPR can be integrated into robot assembly lines to achieve efficient mass production.

According to a study by the European Automobile Manufacturers Association (ACEA), aluminum bodies using SPR technology can reduce weight by 25%-30% compared to traditional steel bodies. This directly leads to lower energy consumption and emissions.

2. Aerospace Industry

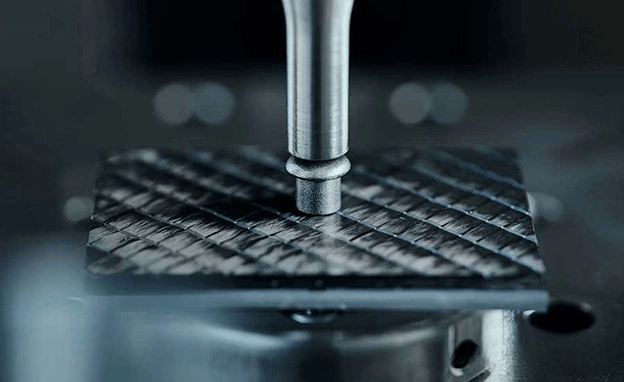

In the aerospace field, self-piercing riveting (SPR) has gradually become the preferred joining process for aluminum alloy and composite material structures.

2.1. Application Scenarios

- The combination of aluminum alloy fuselage skin and composite material frame.

- Multi-layer structural components such as aircraft doors, wings and support beams.

- Lightweight structural assembly for unmanned aircraft and light aircraft.

2.2. Resolution of Pain Points

- Composite materials cannot be welded using traditional methods as welding would damage the fiber structure of the material, resulting in a decrease in strength.

- SPR achieves connections through cold processing, without generating a heat affected zone (HAZ).

- In multi-layer or heterogeneous material combinations, SPR can ensure high strength and long-term stability.

2.3. Value Realization

- Maintain material integrity: Avoid welding thermal damage and preserve the original properties of the composite materials.

- Enhance safety: In high-vibration and fatigue environments, the lifespan of the SPR joints is longer.

- Extend service life: Reduce maintenance frequency and lower the total life cycle cost.

According to the supply chain data of Boeing and Airbus, SPR has been applied in the local assembly of multiple aircraft models, replacing some traditional riveting and gluing processes. Practice has shown that SPR can achieve dual optimization of weight and maintenance costs while ensuring structural reliability.

3. Appliances & Electronics

Self-piercing riveting (SPR) is increasingly being used in the home appliance and electronics industries, and is particularly suitable for metal casings and lightweight structural components.

3.1. Application Scenarios

- The exteriors of household appliances such as refrigerators and washing machines.

- Server chassis and the exteriors of network devices.

- Other metal chassis structures that require lightweight and durability.

3.2. Resolution of Pain Points

- If thin plates and coated metals are welded, the coating is likely to be damaged, resulting in a decline in anti-corrosion performance.

- The traditional screwing method may affect the appearance and requires more processes.

- SPR does not require a heat source and is a cold processing technique, thus it will not damage the surface coating and layer.

3.3. Value Realization

- Aesthetically pleasing: The joints are smooth and free of welding slag or thermal deformation.

- Durable structure: The connection has high strength and can withstand vibrations and impacts during daily use.

- Excellent corrosion resistance: The coating remains intact, extending the service life of the product.

According to the data from the Appliance Manufacturing Association (AHAM), the lifespan of metal casings produced using the SPR process can be extended by 20%-25% compared to those with welded structures, while production efficiency is also improved.

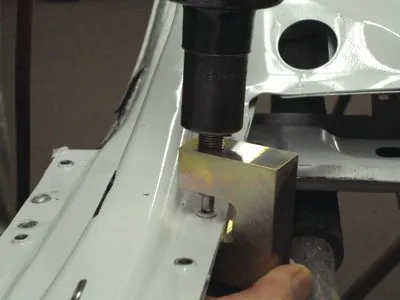

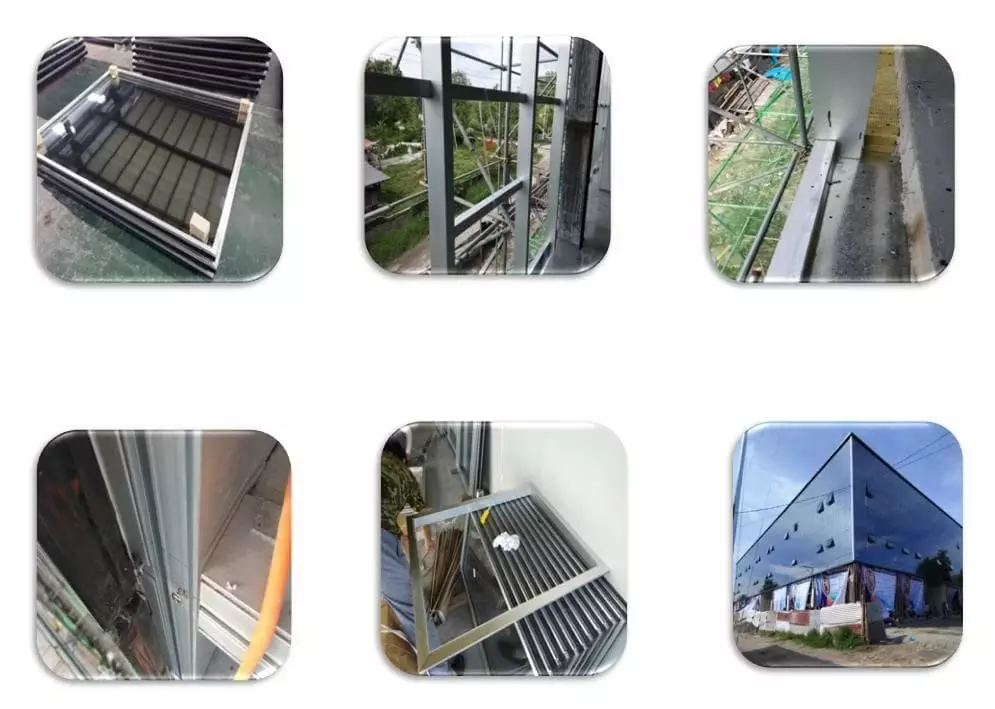

4. Construction & HVAC Systems

Self-piercing riveting (SPR) is gradually gaining popularity in construction and HVAC (Heating, Ventilation, and Air Conditioning) systems. It enables efficient connection of metal sheet structures, thereby enhancing construction and production efficiency.

4.1. Application Scenarios

- Building curtain wall system.

- Air conditioning unit and outdoor unit casing.

- Ventilation ducts and support framework.

4.2. Resolution of Pain Points

In buildings and HVAC equipment, a large amount of coated steel plates and lightweight metal parts are used.

Traditional bolt connections require drilling, which involves multiple processes and is slow.

Welding may damage the coating and increase the cost of subsequent anti-corrosion treatment.

SPR is a cold processing method that does not require drilling or heat sources, and is more suitable for batch automated production.

4.3. Value Realization

- Improve construction efficiency: Eliminate the drilling and post-processing procedures, thereby accelerating the assembly cycle.

- Ensure structural aesthetics: The joints are smooth, without weld slag or additional bolt protrusions.

- Reduce maintenance costs: Maintain the integrity of the coating, reducing corrosion and rework.

According to the test results of the Building Curtain Wall Council (CWCT), the SPR joint performed stably in long-term wind pressure and water penetration tests, and its durability was superior to that of the traditional bolted connection method. This is also the important reason why it has gradually become the preferred connection technology in modern architecture and HVAC industries.

5. Other Emerging Applications

Apart from the automotive, aviation, home appliance and construction industries, self-piercing riveting (SPR) has also demonstrated great potential in other sectors.

Railway and Transportation

- SPR can be used for lightweight carriages, door panels and structural components.

- Compared to welding, SPR can reduce thermal deformation and ensure assembly accuracy.

- In high-speed trains and subway vehicles, SPR helps to reduce weight and improve energy efficiency.

Renewable Energy

- SPR can be applied to wind turbine towers, solar support structures and lightweight metal frameworks.

- It can form a high-strength connection between coated steel and composite materials.

- Compared to bolt connections, SPR joints are smoother and have lower maintenance costs.

Industrial Equipment

- In heavy machinery and production equipment, some components require long-term and reliable multi-material connections.

- SPR can provide stable shear resistance and fatigue resistance, thereby extending the equipment’s lifespan.

- It is particularly suitable for scenarios that require low maintenance and high durability.

Advantages That Drive These Applications

Self-piercing riveting (SPR) has been able to rapidly gain popularity across various industries, primarily due to its combination of efficiency, strength, and environmental friendliness. Firstly, SPR excels in compatibility with different materials. It can easily connect various combinations such as aluminum + steel, coated steel + composite materials, and traditional welding often struggles to achieve stable joints in these scenarios.

SPR is highly suitable for highly efficient automated production. Since it does not require pre-drilling, it can be directly integrated into the robot production line. Compared with the traditional drilling + riveting process, the overall cycle efficiency can be improved by up to 20%-30%.

In terms of environmental protection and safety, SPR is a cold processing technique. It does not produce the common smoke, sparks or slag seen in welding, thus avoiding potential hazards to operators and the workshop environment. Additionally, it consumes less energy, aligning with the low-carbon trend in global manufacturing.

Strength and durability are also important advantages of SPR. SPR joints not only have excellent shear resistance, but also can remain stable in high-vibration environments, and their fatigue life is superior to spot welding. This is particularly crucial in structures that are subjected to long-term loading and impact, such as in automobiles and aviation.

Finally, from the perspective of overall economy, although the initial equipment investment of SPR is relatively high, its high consistency and low rework rate significantly reduce the maintenance and scrap costs in the later stage. For enterprises that pursue high quality and long-term reliability, the cost of SPR throughout its entire life cycle is lower.

Rivmate Expertise & Solutions

Rivmate specializes in the self-piercing riveting (SPR) technology and is capable of providing comprehensive product and service support for various industries. Our solutions not only cover a wide range of working conditions but also help customers achieve efficient and reliable production.

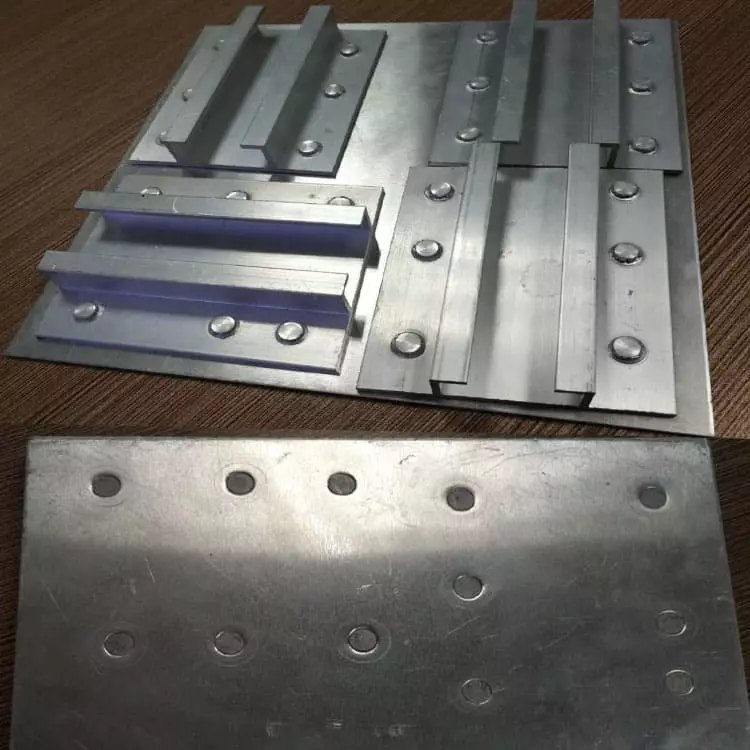

Coverage of Rivmate SPR Products

- Various materials: Steel, stainless steel, aluminum, meeting different strength and corrosion resistance requirements.

- Comprehensive Grip Range: Suitable for connection needs ranging from thin plates to multi-layer structures.

- Strict compliance with standards: All products comply with the international standards of ISO 14589 and DIN 7337, ensuring quality and consistency.

Rivmate's Service Capabilities

- Industry-specific customized solutions: Provide professional connection process support for sectors such as automotive, aviation, construction, and home appliances.

- SPR process evaluation and selection guidance: Based on material combinations and structural requirements, assist customers in choosing the most suitable rivets and process parameters.

- Support for automation production compatibility: Assist customers in integrating the SPR process into robots and automated production lines, thereby enhancing efficiency and consistency.

Choosing Rivmate not only enables you to obtain high-performance SPR rivets, but also provides you with full-chain support from model selection to process validation, from small-batch trial production to automated production. Our goal is to help customers reduce risks, improve efficiency, and achieve higher connection reliability.

FAQs

Q1: Why does the automotive industry particularly favor SPR?

Answer: The automotive manufacturing industry is currently trending towards lightweighting and the integration of multiple materials. Traditional welding has limitations in connecting aluminum and coated steel, and it is prone to creating heat-affected zones. SPR, on the other hand, does not require a heat source and can achieve stable connections in structures made of different materials such as aluminum and steel. Therefore, car manufacturers like Tesla, Jaguar Land Rover, and BMW have adopted the SPR process on a large scale.

Q2: Can SPR completely replace welding?

Answer: It cannot completely replace. SPR performs exceptionally well in aluminum alloys and multi-material connections, but for extremely thick plates or high-load structures, welding still has a greater advantage. Therefore, SPR is usually combined with welding, structural adhesives, and other processes to achieve the best strength and durability.

Q3: Is SPR suitable for high-strength steel?

Answer: SPR can connect some high-strength steel, but it requires choosing the appropriate rivet material and mold design. If the steel is too hard, the rivets may not be able to penetrate effectively. In such cases, process verification is necessary to ensure the quality of the joint.

Q4: Does Rivmate offer training on the SPR process?

Answer: Yes. Rivmate not only offers high-quality SPR rivets, but also provides training on the manufacturing process and selection guidance. Our engineering team can assist customers in equipment debugging, process validation, and production line integration, ensuring the stability and reliability of SPR in actual production.

Transform Your Manufacturing with Rivmate SPR Solutions

Rivmate invites you to download the latest SPR Industry Application White Paper, to gain a deep understanding of the practical applications and best practices in various industries. Additionally, our technical team can provide you with customized process assessment and solutions, ensuring that each riveting operation achieves the optimal performance.

Contact us immediately to unlock the efficiency, strength and long-term value brought by the SPR process.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met