Table of Contents

Blind rivet mandrel is an important part of the blind rivet. This article will explain to you the importance of the blind rivet mandrel and everything you should know about it.

Table of Contents

What is the Mandrel on a Blind Rivet?

The Blind Rivet Mandrels are part of the Blind Rivet and is a very critical component in the rivet installation process. Blind rivets typically consist of two parts: the body of the rivet (usually hollow) and the blind rivet mandrel. The Mandrel runs through the body of the rivet and plays a key role in the installation process.

When installing blind rivets, a riveting tool is used to pull the blind rivet mandrels so that the rivet body of the blind rivet can expand to form a stable connection. Therefore, the design and performance of the blind rivet mandrels will have a direct impact on the installation of the blind rivet, the strength of the connection and the overall reliability.

What Are the Benefits of a Blind Rivet Mandrel?

In the working principle of the Blind Rivet, the normal expansion of the rivet body is driven by the Blind rivet mandrels.Blind rivet mandrels are the core component of the Blind Rivet in the riveting process, which directly affects the installation of the Blind Rivet. The following are the main roles of the blind rivet mandrels in a blind rivet.

1. Expansion Rivet Body

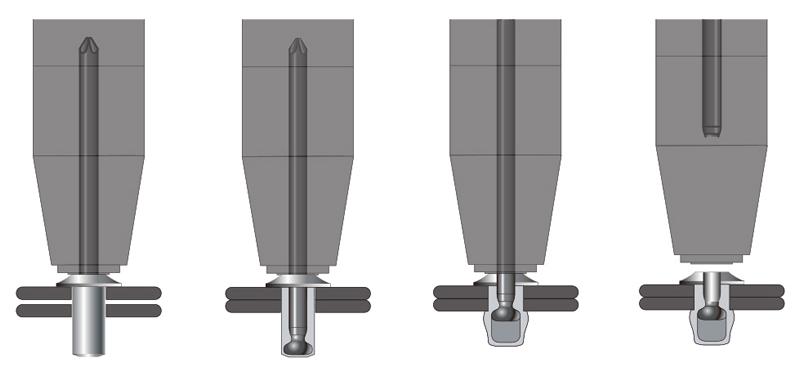

Blind rivets are typically installed using a specialised rivet gun. During the installation process, the operator will use the rivet gun to pull the blind rivet mandrel through the end of the rivet body. This process causes the end of the rivet body to expand, forming a mushroom or similar shape, which secures the rivet in the material.

The proper blind rivet mandrels ensure that the rivet expands correctly within the material to form a solid joint. Without the pull of the mandrel, the rivet cannot expand and an effective riveted joint cannot be achieved.

2. Forming a Strong Connection

The blind rivet mandrels are pulled as the rivet body expands. The greater the force pulling the mandrel, the more uniformly the blind rivet will blind rivet expand and the stronger the connection will be.

3. Auto-Break Ensures Consistent Installation

A blind rivet has a special design. When the mandrel is pulled to a certain predetermined tension, it automatically breaks at a specific location. This unique design ensures that every rivet is installed in the same manner and with the same force.

4. Provides Additional Strength Support

During installation of structural blind rivets, a portion of the mandrel remains in the rivet body after breakage. This design enhances the pulloutq and shear strength of the blind rivet.

In practice, applications such as those requiring high load capacity choose to use these blind rivets.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Types of Blind Rivet Mandrel

There are many types of blind rivet mandrels depending on the actual application.

Material

There are several common metal blind rivet mandrels:

- Aluminum Mandrel

- Steel Mandrel

- Stainless Steel Mandrel

- Copper Mandrel

Application

There are many types of blind rivet mandrels depending on the application requirements and rivet design, each with specific uses and characteristics. Below are a few common types of blind rivet mandrels:

- Standard Blind Rivet Mandrel: The most common type. Mandrels break automatically when a specific tensile force is reached and are suitable for light to medium load applications. E.g. joining of sheet metal, plastics and composites.

- High-Strength Mandrel: Made from higher strength materials such as high carbon steel or stainless steel. Suitable for high loads and critical structural connections. Such as construction, bridges, aerospace and automotive manufacturing.

- Extended Mandrel: The Extended Mandrel is longer than the standard mandrel and is suitable for installation in thicker materials or where deeper embedding is required.

- Retained Mandrel: This blind rivet mandrel does not break completely after installation, a portion of the mandrel remains in the rivet body, increasing the shear and pull-out strength of the rivet.

- Locking Mandrel: Locking Mandrels have a special design that allows a portion of the mandrel to be locked into the rivet body as the rivet expands. This design increases the stability and strength of the joint and prevents the rivet from loosening.

Structural Rivet vs Blind Rivet : Blind Rivet Mandrel

Although structural rivet is one of the blind rivet. But there are still many differences between them. The differences in the blind rivet mandrels will be explained here.

1. Mandrel Strength and Material

The mandrels of structural rivets are typically made of high-strength materials, such as high-carbon steel or stainless steel. These mateials are capable of withstanding greater tensile and shear forces. These materials will not break or fail prematurely under high stress conditions.

The mandrels of blind rivets are designed to accommodate general industrial and consumer applications and are not normally subjected to particularly high stresses. For this reason the mandrels of blind rivets are usually made of materials such as mild steel, aluminium or copper, which are sufficient for light duty connections.

2. Mechanism of Breakage of Mandrels

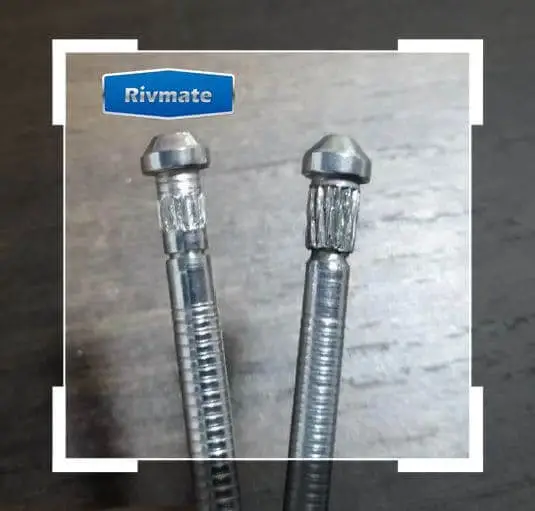

The breakage mechanism of structural rivet mandrels is designed to be very precise. This breakage mechanism ensures that the mandrel breaks after a predetermined tension is reached and a portion of the mandrel remains inside the rivet. This retained portion of the mandrel adds to the overall strength of the rivet.

Blind rivets, on the other hand, have a mandrel that breaks at a predetermined breaking point after the rivet is fully expanded, usually near the head of the rivet.Blind rivet mandrels do not retain much of the mandrel inside the rivet.

3. Applicable Scenes and Design Complexity

Structural rivets are mainly used in construction, aerospace, automotive manufacturing and other application environments that require high strength and reliability. The design of its mandrel is more complex and requires additional structural support for the rivet after breakage.

Whereas, blind rivets are suitable for scenarios such as general industry, consumer products and lightweight structures. Its blind rivet mandrel is relatively simple in structural design. And the main function of its blind rivet mandrel is to ensure rapid expansion and installation of the rivet.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Conclusion

For blind rivets, the blind rivet mandrel is an indispensable part. Blind rivets are usually manufactured separately from the blind rivet mandrels during the production process and then assembled.

Blind rivet mandrels are also available in many types to suit different applications. Trust Rivmate to find the best blind rivet mandrels for you.

Custom Blind Rivet Mandrel from Pop Rivet Manufacturer

Are you looking for reliable pop rivet manufacturer? Do you want to buy high quality blind rivet and structural rivets for your project?

Don’t worry, at Rivmate, you will buy it all. Whether you are looking for a regular blind rivet mandrel or a custom blind rivet mandrels, Rivmate can produce it for your project.