Table of Contents

There are still more parts of the furniture that use blind rivets. So do you know how to choose blind rivets for furniture? Do you know what type of blind rivets should be used for different materials of furniture? Through this article, you will know all this information.

Table of Contents

Why Use Blind Rivets for Furniture?

In our homes, there will be furniture present that is manufactured from a variety of materials. So do you know how they are assembled and fixed? Blind rivets play an important role in assembling furniture. So do you know why blind rivets for furniture are used? Here are a few of the most common reasons.

1. Easy to Operate

Using blind rivets in furniture is very simple. Requiring installation on only one side of the component being joined, this type of installation is ideal for joining parts in furniture where the back side is difficult to reach. Example:

- Enclosed structures: e.g. steel frames, drawer slides, etc.

- Tubular or hollow parts: e.g. table and chair legs, metal frames of cabinets.

In addition to this, the installation process for blind rivets is very fast. Blind rivets are installed by means of a rivet gun without welding or complicated threading.

Blind rivets are ideal for assembly line production. It improves the efficiency of factory-installed furniture compared to other joining methods.

2. Provides Strong Connections

Blind rivets are mechanically deformed by the rivet tail to create a reliable clamping force. This type of connection can withstand certain loads and vibrations.

Therefore, blind rivets are very suitable for the assembly and connection of furniture with metal frames, such as steel desks, filing cabinets and so on. Moreover, rivets do not loosen due to vibration as screws do when properly installed.

3. Economics

Furniture rivets are less expensive to join than welded or high-precision threaded connections.

- The low price of rivets makes them more economical, especially when used in large quantities.

- The tools used to install rivets are simple and do not require expensive welding equipment.

4. Environmentally Friendly

Using blind rivets for furniture is very friendly to the environment. The use of blind rivets avoids chemical contamination from adhesives or energy consumption from welding. This advantage helps furniture companies to comply with environmental requirements (e.g. no VOC emission standards).

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

What Are the Different Types of Blind Rivets for Furniture?

There are many different types of furniture rivets to suit different furniture.

Dome head blind rivets are characterized as follows:

- Head shape: round head design, suitable for most common connections.

- Advantage: Provides uniform clamping force and low cost.

Dome head blind rivets on furniture include:

- Connection of table legs to beams in metal-framed furniture

- Frame connections for steel desks or filing cabinets

- Fixing of wooden table tops to metal brackets

Large flange head blind rivets have a larger brim area, which greatly increases the contact area between the rivet and the surface of the furniture. This rivet head design effectively distributes pressure and prevents thin or soft materials from being pulled through. Therefore, large flange head blind rivets are often used in the following scenarios:

- Attachment of cabinet doors and drawer fronts to brackets.

- Fixing of plastic or composite furniture components.

- Connection of wooden armrests or backrests in sofa frames.

Counterusnk blind rivets have a concealed rivet head that is flush with the surface of the material after installation. This head design is ideal for scenarios where the surface needs to be flat or aesthetically pleasing.Common applications for Countersunk blind rivets on furniture include:

- Attachment of metal trim or inserts to table tops or cabinets

- Shell splices for steel filing cabinets

Closed end blind rivets have a closed rivet tail to provide a good seal. It is ideal for use on furniture that needs to be protected from moisture and dust.

- Bathroom or kitchen furniture: metal frame splices for moisture-proof cabinets.

- Outdoor furniture: metal parts splicing of balcony tables and chairs to prevent rainwater from entering.

Exploding rivets split at the end when the rivet is pulled, creating multiple support points. In furniture, exploding rivets are commonly used in the following areas:

- Splicing of cork or honeycomb structured panels

- Lightweight frame fixing in collapsible furniture

In the Blind Rivet product line, multi grip blind rivets are the most used type of rivets besides open end blind rivets. Its most important feature is that one rivet size can be used to join a wide range of materials in a wide range of thicknesses. It is often used in the following types of applications.

- Assembled furniture: joining metal frames to wood panels of varying thicknesses

- Occasions with high assembly uncertainty: fixing of multiple layers of material in DIY furniture or modular furniture

Grooved type blind rivets have a grooved surface for added grip when riveting. This type of blind rivet is ideal for use on harder or smoother materials. For example:

- Metal to hardwood connection: metal support structure for solid wood dining table

- High-load furniture: steel tube and wood panel combination for industrial-style furniture

Structural Rivets

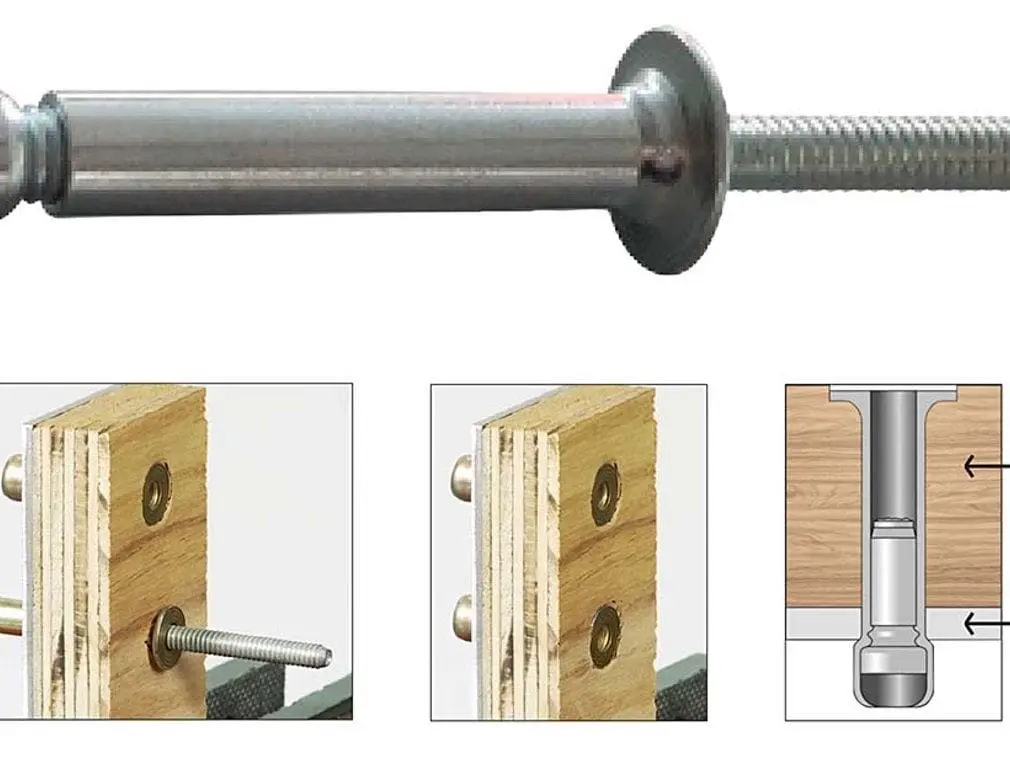

Monobolt rivets and interlock rivets represent structural rivets. Their design features a rivet mandrel that locks to the shell, providing higher strength and vibration resistance.

If your project requires the use of blind rivets in removable furniture (tool cabinets or filing cabinets with pulleys) or high-strength furniture (metal frame splicing for commercial furniture or heavy duty shelving), then structural rivets are the best choice.

What are the Best Rivets for Wood?

Blind rivets for joining wood need to be characterized:

- Will not pull through the wood

- No damage to the material surface of the wooden furniture

- Provide a stable and strong clamping force

Based on the above requirements, the following rivets are ideally suited for riveting wood.

- Large flange blind rivets

- Exploding rivets

- Peel Type Blind Rivets

- Multi grip blind rivets

How to Choose Blind Rivets for Furniture?

There are many types of raw materials used to manufacture furniture, including wood, metal, plastic or composite materials and multi-material combinations (e.g. wood + metal). Depending on the furniture material to be joined, there is a difference in the type of blind rivet to choose. So HOW to choose the right blind rivets for furniture?

If you want to learn about how to choose right size pop rivets, read the hyperlinked article.

Selection of Rivets According to the Material of the Furniture

| Furniture Material | Recommended Rivet Type | Reason |

| Wood | Large Flange Rivets, Exploding Rivets, Split Rivets | Provide a larger clamping area to prevent cracking or pull-through; ideal for softwood, thin wood panels, or composite wood. |

| Metal | Steel Rivets, Stainless Steel Rivets, Aluminum Shell Steel Core Rivets | Ensure high-strength connections and resist loosening under dynamic loads; stainless steel rivets for corrosion resistance, aluminum shell steel core rivets for lightweight designs. |

| Plastic or Composite Materials | Large Flange Rivets, Exploding Rivets, Sealed Rivets | Prevent cracking under concentrated pressure; large flange and exploding rivets distribute stress; sealed rivets work well in humid environments. |

| Multi-material Combinations (e.g., Wood + Metal) | Multi-Grip Rivets | Adapt to varying thicknesses and material combinations without requiring multiple rivet specifications, improving versatility. |

Consider the Use and Stress Requirements of the Furniture

| Usage Category | Key Requirements | Recommended Rivet Type | Reason |

| Office Furniture | High strength, durability | Steel Rivets, Stainless Steel Rivets | Suitable for metal frames, providing secure connections and good vibration resistance, especially for filing cabinets, desks, etc. |

| Outdoor Furniture | Corrosion resistance, moisture-proof | Stainless Steel Rivets, Sealed Rivets | Stainless steel rivets resist corrosion, and sealed rivets prevent water penetration, ideal for garden tables or patio furniture. |

| Lightweight Furniture | Lightweight, flexible connections | Aluminum Rivets, Large Flange Rivets | Aluminum rivets are lightweight, and large flange rivets distribute pressure, ideal for wooden or plastic furniture. |

| Decorative Furniture | Aesthetics, concealed connections | Countersunk Rivets, Decorative Rivets | Countersunk rivets are flush with the surface for a clean look, while decorative rivets enhance appearance. |

| Modular or DIY Furniture | Adaptability to varying thicknesses, quick assembly | Multi-Grip Rivets, Exploding Rivets | Multi-grip rivets accommodate materials of different thicknesses, and exploding rivets provide a firm hold on diverse materials. |

Custom Blind Rivets Solutions for Your Furniture Project

Are you looking for blind rivet manufacturer for your furniture project? Do you not know how to utilize blind rivets to enhance your furniture business? Don’t worry, contact our engineers now and you will get furniture rivet solutions!