Can Blind Rivets Be Self-Piercing?

Table of Contents

In the application of fasteners, many users may have such a question: “Can blind rivets be self-piercing?” Blind rivets and self-piercing rivets (SPR) have certain similarities in appearance and application scenarios, so they are often confused. Both can achieve single-sided operation and are used in structures where the back side cannot be accessed. However, this does not mean that they can be used interchangeably.

The core issue is: Does the blind rivet have the self-pushing function? Can it be used for two purposes with one rivet? This article will conduct an in-depth analysis from three aspects: structural principle, installation method, and application scenario.

Blind rivets are a common type of mechanical fastener. Their most notable feature is “single-sided installation”. This means that assembly can be completed even if the back of the structure cannot come into contact.

The working principle of blind rivets is very straightforward. During installation, first drill holes on the workpiece. Insert the rivet and then use a special riveting gun to pull the mandrel. The mandrel will force the rivet body to expand and compress the material. Eventually, the rivet is locked in the hole, the mandrel breaks and remains inside the rivet, forming a reliable connection.

Blind rivets have a wide range of applications. They are commonly found in electronic enclosures, sheet metal parts, household appliances and lightweight metal structures. These industries have high requirements for installation efficiency and cost control. Blind rivets do not require double-sided operation, the riveting tools are lightweight, the installation speed is fast, and therefore they are very popular in mass production.

In terms of material selection, blind rivets can be made of aluminum, steel, stainless steel, copper, etc. Different materials are suitable for different needs. For instance, aluminum-made blind rivets are lightweight and are suitable for the home appliance and electronics industries; stainless steel blind rivets have strong corrosion resistance and are more suitable for outdoor and humid environments. According to market data, in the sheet metal assembly and electronics industries, the usage proportion of aluminum-made blind rivets exceeds 50%.

It should be noted that blind rivets must rely on pre-drilled holes. If the hole diameter does not match the rivet diameter, or if the clamping force is insufficient, it may lead to loosening or even failure. Therefore, in engineering applications, choosing the appropriate hole size and adopting the correct installation process is of utmost importance.

The Self-Piercing Rivet (abbreviated as SPR) is an advanced mechanical connection method. Unlike blind rivets, it does not require pre-drilling. During the installation process, the rivet pierces the upper layer material under high pressure. Subsequently, the tail of the rivet expands in the lower layer material, thereby forming a secure mechanical lock.

The greatest advantage of this process is that it is suitable for the connection of different materials. Traditional welding would encounter difficulties in such combinations, but SPR can ensure a high-strength connection without compromising the material properties.

The application fields of SPR are very extensive. The automotive industry is the main market. With the trend of lightweighting, many car bodies adopt aluminum structures, and SPR has become an important process to replace spot welding. According to industry data, over 70% of aluminum body parts in high-end European cars are produced using the SPR process.

In the field of aerospace, SPR can efficiently connect aluminum alloys and composite materials, ensuring structural strength and reliability. In the construction and composite materials industry, SPR is also gradually being adopted for the manufacturing of curtain walls, lightweight steel structures, and new energy equipment.

SPR also has environmental benefits. It does not require a heat source, does not produce smoke or sparks, and does not form the “heat affected zone” commonly seen in welding. Therefore, SPR can maintain the original mechanical properties of the material while reducing energy consumption.

Can Blind Rivets Be Self-Piercing?

The answer is very clear: No.

Blind rivets and self-piercing rivets (SPR) both belong to the single-sided installation fastening methods, but their principles and processes are completely different. Blind rivets cannot achieve the self-tapping function. Each of them is designed for different application scenarios and cannot be interchanged.

a. Different structures

- The blind rivets must rely on the pre-drilled holes. Before installation, appropriate holes need to be drilled on the workpiece, and then the rivets can be inserted.

- Self-piercing rivets have a special geometric structure. Under high pressure, they can directly pierce through the upper layer material and expand and lock in the lower layer material, without the need for pre-drilling holes.

b. Different Installation Methods

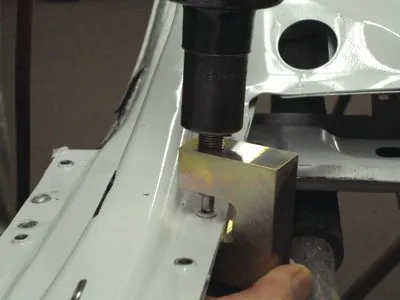

- Blind rivets are installed using a riveting gun or hand tools. The operation is simple, but the requirements for hole size accuracy and installation quality are high.

- SPR requires a dedicated high-pressure hydraulic press or servo riveting equipment. The equipment cost is higher, but it can ensure repeatability and connection strength.

c. Different Applicability of Materials

- Blind rivets are more suitable for thin plates with pre-drilled holes, and are commonly used in lightweight structures and conventional metal assemblies.

- SPR is specifically designed for un-drilled multi-layer materials or dissimilar materials (such as aluminum + steel, steel + composite materials), and is suitable for scenarios with higher requirements for strength and durability, such as in automobiles and aviation.

Why Are Blind Rivets and SPR Confused?

In the selection of fasteners, many users tend to confuse blind rivets with self-tapping rivets. This confusion is not surprising. The main reasons are as follows:

1) All are one-sided operations

Both can be installed without being able to access the back side. For the assembly workers, this “single-sided installation” feature is very similar.

2) Both can be used in thin plate scenarios

Blind rivets are commonly found in sheet metal parts and lightweight structures. SPR is also frequently used in the combination of aluminum alloy sheets or plates. When users actually assemble, they often find that their application scopes overlap.

3) All fall under the category of alternative welding or bolting methods

In modern manufacturing, riveting and SPR are both widely used as alternative solutions to welding and bolt connections. Both of them can, to a certain extent, reduce the complexity of the process and improve the assembly efficiency.

However, it must be emphasized that: Blind rivets ≠ Self-tapping rivets.

- Blind rivets require pre-drilled holes, while SPRs do not need any pre-drilling at all.

- Blind rivets are mostly used in conventional lightweight structures, while SPRs are specifically designed for high-strength and heterogeneous material connections.

Blind Rivets vs. Self-Tapping Rivets

Comparison Table: Blind Rivets vs. Self-Tapping Rivets

| Feature | Blind Rivets | Self-Piercing Rivets (SPR) |

|---|---|---|

| Pre-drilled Hole Required | Yes | No |

| Installation Method | Rivet Gun (Mandrel Pulling) | Hydraulic/Servo Riveting Machine |

| Self-Piercing Capability | No | Yes |

| Suitable Materials | Metals, Plastics, Thin Sheets | Multi-materials, Aluminum + Steel, Layered Sheets |

| Removability | No | No |

| Typical Applications | Electronics, Light Industry, Appliances | Automotive, Aerospace, Construction |

① Is pre-drilling required

- The blind rivets must be drilled first before being installed.

- The SPR directly pierces through the upper layer material without requiring any additional processes.

② Different Installation Methods

- Blind rivets rely on pull-pin guns and are suitable for portable and lightweight operations.

- SPR requires high-pressure riveting machines and is mostly used in automated production lines.

③ Differences in Self-Drilling Ability

- Blind rivets cannot self-tap.

- SPR is precisely because of its self-tapping feature that it performs exceptionally well in the connection of different materials such as aluminum and steel.

④ Different applicable materials

- Blind rivets are suitable for thin sheets or plastic parts of a single material.

- SPR is specifically designed for multi-layer and heterogeneous materials, making it more suitable for the trend of lightweight manufacturing.

⑤ Application Field Differences

- Blind rivets are more commonly used in the fields of electronics, home appliances, and light industry.

- SPR is mainly found in high-demand areas such as automobiles, aviation, and building structures.

When to Use Blind Rivets vs SPR

Advantages of Blind Bolts

- Low cost, suitable for large-scale use.

- Easy installation, low operational threshold.

- Portable tools, enabling rapid construction on-site.

- Typical applications: electronic enclosures, home appliance assembly, furniture, lightweight metal parts.

- High strength, with superior connection performance compared to traditional blind rivets.

- Particularly suitable for dissimilar materials, such as aluminum alloy and steel.

- Easy to integrate into automated production lines, resulting in higher efficiency.

- Typical applications: automotive lightweight body, aerospace aluminum alloy and composite materials, building curtain walls, and new energy equipment.

How to Choose?

If the project requires low cost and easy installation → Choose blind rivets.

If the project requires high-strength or special material connections → choose self-tapping screws.

In high-end manufacturing industries such as automotive production, SPR has gradually replaced traditional welding and some riveting processes. Data shows that over 70% of aluminum body panels in the European market are produced using the SPR process.

Rivmate Expertise & Recommendations

In different projects, the choice of riveting method directly affects the structural performance and service life. Rivmate, as a professional fastener supplier, can offer a complete range of products including blind rivets and self-tapping rivets (SPR) to meet the diverse needs of customers.

1. Multiple material options available

The Rivmate products cover various materials such as aluminum, stainless steel and carbon steel.

- Carbon steel → High strength, suitable for automobiles and structural components.

- Aluminum → Lightweight, suitable for home appliances and electronics industries.

- Stainless steel → High corrosion resistance, suitable for marine, construction and outdoor projects.

2. Adapt to different application requirements

Rivmate blind rivets are suitable for lightweight assembly and portable construction.

SPR is suitable for high-strength, multi-layered boards and connections between different materials. Whether in the manufacturing of household appliances or in the lightweight body structure of automobiles, there are matching solutions available.

3. Technical Support and Model Selection Guidance

The technical team of Rivmate has over 20 years of experience in fastener application. We not only offer standardized products, but also provide customized recommendations based on the customer’s working conditions. Through selection guidance and process evaluation, we help customers avoid quality or cost risks caused by choosing the wrong riveting method.

Therefore, if you are unsure whether to choose blind rivets or self-tapping rivets, Rivmate can offer you a one-stop solution to ensure that the performance of the fasteners and production efficiency achieve the optimal balance.

FAQ

Q1: Are there any blind rivets that can partially "self-tap"?

Answer: No. All blind rivets must rely on pre-drilled holes. This is the fundamental difference between them and self-tapping rivets.

Q2: Can the self-tapping rivet installation tool be used to install blind rivets?

Answer: No. The manufacturing processes and equipment for the two are completely different. Blind rivets are made using a pull core gun, while self-tapping rivets require hydraulic or servo riveting machines.

Q3: If I need lightweight and connection with different materials, which option should I choose?

Answer: Self-tapping rivets (SPR) are more suitable. They can achieve high-strength connections in multi-layer or heterogeneous materials such as aluminum and steel. According to industry data, in the manufacturing of lightweight automotive bodies in Europe, over 70% of aluminum parts are produced using the SPR process.

Q4: Can Rivmate provide a comparison and selection guide for blind rivets and SPR?

Answer: Yes. Rivmate not only offers standardized product catalogs, but also provides professional selection comparison tables and process recommendations based on actual working conditions, helping customers avoid incorrect usage.

Conclusion

Blind rivets cannot self-drive. They differ fundamentally from self-driving rivets in terms of installation principles, applicable materials, and strength performance. However, they also share some common points: both support single-sided operation and can provide reliable mechanical connections. In actual selection, the following aspects should be given priority consideration:

- Is pre-drilling required?

- Is the material of a heterogeneous or multi-layered structure?

- What are the specific requirements for strength and durability?

Choosing the correct fastening method is essential to ensure the structural safety while optimizing the cost and assembly efficiency.

Whether you are considering blind rivets or planning to adopt self-piercing rivets, Rivmate can offer you professional selection guidance and complete solutions. We not only have product series covering aluminum, stainless steel, and carbon steel, but also can provide customized process suggestions based on your industry requirements.

Contact us immediately to obtain the “Blind Rivets vs Self-Tapping Rivets Selection Guide”, and choose the best fastening solution for your project.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met