Closed End Rivets for Aluminum Boat: The Complete Guide

Table of Contents

In the manufacturing and maintenance of aluminum vessels, the selection of fasteners directly determines the sealing performance and lifespan of the hull. Ordinary open rivets will corrode, loosen, and even leak water due to prolonged exposure to seawater and salt fog, ultimately affecting the structural safety of the vessel. Closed End Rivets for Aluminum Boat can provide strong mechanical locking. At the same time, it prevents water and air from penetrating, offering long-term anti-corrosion protection for aluminum vessels.

What Are Closed End Rivets and Why They Matter for Aluminum Boats

Closed End Rivets is a design of blind rivets with a completely sealed tail end. After installation, it can effectively prevent water, oil or gas from seeping into the tail end, thus achieving a 100% sealed connection.

a. Structure and Principles

The closed-type rivet is composed of a rivet body and a mandrel. During installation, the mandrel is pulled, causing the tail of the rivet body to undergo plastic deformation and forming a tightly sealed cavity.

When the core shaft is broken, the closed end seals the tail hole, thereby preventing any liquid or gas from passing through. This structure ensures the air tightness and water resistance of the joint, and suitable for applications in areas that are constantly submerged in water or have high humidity.

The closed-type rivet is composed of a rivet body and a mandrel. During installation, the mandrel is pulled, causing the tail of the rivet body to undergo plastic deformation and forming a tightly sealed cavity.

When the core shaft is broken, the closed end seals the tail hole, thereby preventing any liquid or gas from passing through. This structure ensures the air tightness and water resistance of the joint, and is particularly suitable for applications in areas that are constantly submerged in water or have high humidity, such as the bottom of ships, cabin joints, and aluminum plate connections.

b. Performance Comparison and Advantages

Compared with traditional open-ended blind rivets, the closed-type rivets have the following significant advantages:

- Waterproof, oilproof, and gasproof —— Ensures that the aluminum hull seams will not leak over a long period of time.

- Strong corrosion resistance —— Suitable for marine and high-salt environment.

- Prevents core shaft from falling off —— The core shaft is fully locked in the rivet, preventing internal rust or loosening.

- Higher structural integrity —— Suitable for long-term fixation in high-vibration and high-humidity environments.

c. Relevant Standards and Industry Certifications

The performance of closed-type rivets generally complies with the following international standards:

- ISO 15983 – Standard for blind rivet structure and mechanical properties.

- ASTM F1470 – Specification for blind rivets and corrosion resistance tests.

In the manufacturing of marine equipment and aluminum hulls, the selection of closed-type rivets that meet these standards can significantly enhance the water resistance and long-term durability of the hull.

Why Use Closed End Rivets for Aluminum Boats?

1. Watertight Sealing

The tail end of the closed-type rivets will form a completely sealed cavity during installation, effectively preventing water, oil or gas from seeping in from the back. This characteristic is particularly important in the hull bottom, aluminum plate joints and cabin seam areas, ensuring that the ship remains dry and sealed even when submerged for a long time. Moreover, the sealing structure can also prevent electrochemical reactions and avoid aluminum oxidation caused by water retention.

2. Corrosion Resistance

The marine environment has high salinity and high humidity, which accelerates metal corrosion. Closed-type rivets are usually made of aluminum alloy, stainless steel or Monel. These materials have excellent corrosion resistance in salt spray environments. In particular, 316 stainless steel closed-type rivets can maintain no-corrosion performance for over 1000 hours in the ASTM B117 salt spray test, making them ideal for use in marine and freshwater vessels. This durability ensures that the hull remains stable and reliable during long voyages and berthing.

3. Vibration & Shear Resistance

During the ship’s movement, it will experience continuous vibration and periodic impacts. If the connecting parts become loose, it will lead to structural cracks or even leakage.

During the installation process of the closed-type rivets, the core shaft is locked inside the rivet body, forming a high-strength mechanical locking structure. This design offers excellent shear and tensile strength, effectively resisting wave impacts and engine vibrations. Compared to ordinary open rivets, its structural integrity is stronger, significantly extending the service life of the hull.

4. Lightweight Strength

The closed-type aluminum rivets are not only lightweight but also have an excellent strength-to-weight ratio. They can provide reliable fastening performance without increasing the weight of the hull. This makes them an ideal choice for aluminum hulls, hatch covers, deck assembly, and lightweight fishing boats, among other structures.

Best Materials for Closed End Rivets in Marine Applications

In the assembly and maintenance of aluminum hulls, the choice of rivet material determines the anti-corrosion lifespan and structural stability of the vessel. Selecting the appropriate closed-end rivets for aluminum boat can enhance the waterproof performance and prevent electrochemical corrosion and structural fatigue.

Aluminum rivets are one of the most commonly used fasteners on aluminum ships. They are lightweight and do not have an electrochemical reaction with the aluminum hull, thus avoiding corrosion issues. The closed-type aluminum rivets also maintain excellent waterproof sealing properties, making them particularly suitable for freshwater environments or small vessels.

In addition, aluminum has a high strength-to-weight ratio, which enables it to reduce the overall weight while ensuring structural safety. It is an ideal choice for lightweight vessels, fishing boats, etc. However, in a long-term saltwater environment, the anti-corrosion layer should be inspected regularly to prevent surface oxidation.

b. Stainless Steel Rivets

Stainless steel rivets are renowned for their high strength and excellent anti-corrosion properties. 304 stainless steel is suitable for general freshwater use, while 316 stainless steel, due to its molybdenum content, has a stronger resistance to chloride ion corrosion and is therefore highly suitable for marine environments.

However, during installation, special attention must be paid to the metal compatibility issue: Stainless steel should not come into direct contact with aluminum plates; otherwise, electrochemical corrosion may occur due to potential differences. In practical operations, EPDM / nylon gaskets can be added to the contact surfaces to block the electrical path.

c. Monel Rivets

Monel is a high-end marine alloy composed mainly of nickel and copper. It possesses extremely strong resistance to salt fog and acid-base corrosion, and is hardly corroded even in marine or port environments. Monel rivets are typically used in high-end yachts, military speedboats, and ships engaged in long-term maritime operations. They are costly, but have a lifespan of over 30 years, making them the preferred choice for applications requiring extremely high reliability. According to the ASTM B117 salt fog testing standard, Monel materials can remain free from significant corrosion for over 2000 hours.

How to Choose the Right Closed End Rivets for Aluminum Boats?

① Diameter vs Hole Size

The accuracy of the aperture directly affects the riveting strength and sealing effect. Generally, it is recommended that the hole size be 0.1–0.2 mm larger than the diameter of the rivet. If it is too small, it will cause installation difficulties or deformation; if it is too large, it will result in loosening and water leakage.

For example: When using 4.8 mm rivets, the ideal hole diameter should be 4.9 – 5.0 mm. For closed-type rivets, it is also necessary to ensure that the hole wall is smooth and free of burrs to prevent damage to the waterproof layer.

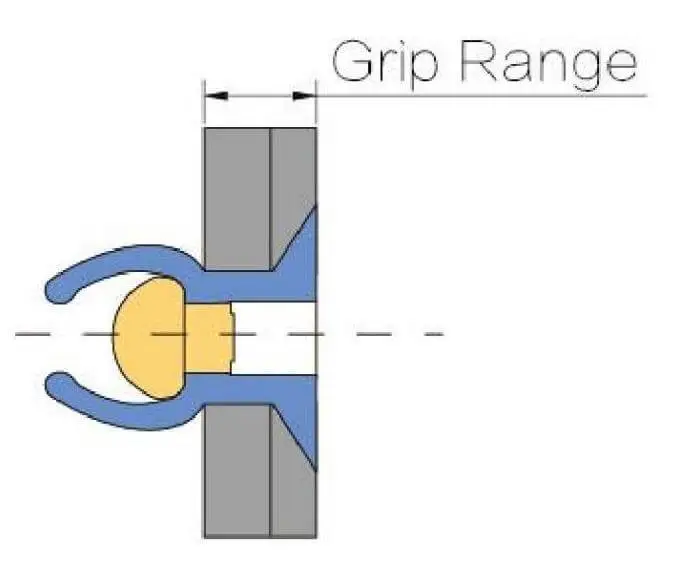

Grip Range refers to the total thickness of the material that the rivet can firmly connect. When choosing, it is necessary to ensure that the Grip Range of the rivet covers the total thickness of two (or more) layers of material; otherwise, the rivet body will not expand sufficiently and the sealing performance will be affected.

Rivmate suggests:

- If the total thickness of the material is 3.5 mm, the model with a Grip Range between 3 and 5 mm should be selected;

- If the thickness varies significantly, the Multi-Grip Structural Rivets (Multi-Clamping Range Structural Rivets) can be used.

Dome Head

- The surface is smooth and the installation is convenient;

- It is suitable for the outer plates, decks, supports and other parts of the hull;

- The round head can better distribute the stress and prevent local depression.

Countersunk Head

- The head is level with the surface, suitable for smooth surfaces or areas with high decoration requirements;

- It is commonly used for ship hull exteriors, cabin door edges, and interior decorative panels;

- Before installation, it is necessary to chamfer the corners in advance to ensure that the rivet head fits perfectly.

④ Material Compatibility

In metal fastening, electrochemical corrosion (Galvanic Corrosion) is a common hazard. When two metals with different potentials come into contact and are exposed to an electrolyte (such as salt water), a small current is generated, causing corrosion. Therefore, the following principles should be followed:

- Aluminum vs. Aluminum: Suitable for freshwater vessels, preventing electrochemical reactions.

- Stainless Steel vs. Stainless Steel: Suitable for high salt spray or marine hulls.

- If it is necessary to use them together, an anti-corrosion gasket (EPDM / nylon) should be added to isolate metal contact.

⑤ Recommended Models by Rivmate

Rivmate offers high-performance rivet solutions specifically designed for marine applications:

- Rivmate Marine Closed-End Series – Specifically designed for marine vessel body sealing assembly, featuring 100% waterproof structure;

- Rivmate Hybrid Rivets – Combination of aluminum and stainless steel core shaft, achieving both lightweight and high strength;

- Rivmate 316 Stainless Rivets – Suitable for high-salt spray and marine environments, with a lifespan of over 25 years.

These products have all passed the ASTM B117 salt spray test and the ABYC H-1 ship structural fastening standard, demonstrating extremely high reliability in actual marine environments.

Maintain Aluminum Boats with Closed End Rivets

The correct maintenance method not only extends the lifespan of the hull, but also enables the closed end rivets to achieve the best waterproof and corrosion-resistant performance.

Conduct a routine inspection of key connection points every six months

The riveted connection points are the core areas where the hull is subjected to force and where sealing occurs. It is recommended to conduct a routine inspection every six months, with a particular focus on the following areas:

- The junction between the bottom of the ship and the cabin;

- The connection points where the supports, decks and outer plates meet;

- The protective cover for the propeller and the area where the fuel tank is fixed.

During the inspection, it is necessary to confirm whether the head of the rivet is flat, and whether there are any signs of loosening, cracks or oxidation. If any minor movement is detected, a Rivmate closed-type rivet of the same specification can be used for re-fastening.

Regularly clean the hull to prevent the accumulation of salt

Salinity is the main factor causing metal corrosion. After each voyage, it is recommended to use high-pressure freshwater rinsing to clean the surface and riveted areas of the vessel, and use a neutral cleaner to remove oil stains. Key cleaning areas include: the bottom of the vessel, the edges of hatches, drainage holes, and rivet joints.

Maintaining dryness can significantly delay the electrochemical corrosion process. For ships that are frequently used at sea, a thorough cleaning and maintenance can be carried out once a month.

If find that the rivets are loose or have rust spots, replace them immediately

Once any looseness, detachment of the cap, or rust spots are observed on the rivets, they must be replaced immediately. Especially for the open-type rivets, the internal cavity is prone to accumulate salt, accelerating corrosion. When replacing, it is recommended to use Closed End Rivets first to ensure that the new joint has complete sealing performance.

Rivmate suggests using rivets of the same material or of a higher grade (such as 316 stainless steel or Monel) to prevent electrochemical reactions caused by metal mismatch.

Use Rivmate 316 stainless steel closed-type rivets for reinforcement and maintenance

After long-term use, even if there are no obvious structural issues, regular protective reinforcement can be carried out. The 316 stainless steel closed-type rivets series of Rivmate is specifically designed for marine environments. It has passed the ASTM B117 salt spray test for 1000 hours and demonstrates outstanding corrosion resistance.

Reinforcement and maintenance can be carried out under the following circumstances:

- There are minor water seepage issues in the weld areas of the hull;

- There is slight deformation at the aluminum plate joints;

- The bottom of the ship or the compartments need to have enhanced anti-vibration connections.

This type of preventive maintenance can extend the lifespan of the aluminum ship structure by 3 to 5 years and reduce the risk of major repairs in the future.

FAQ

Q1: What size closed end rivets should I use for aluminum boats?

The size of the rivets should be determined based on the total thickness of the ship’s hull plates (Grip Range). Generally speaking, the diameter of the hole should be 0.1–0.2 mm larger than the diameter of the rivet to ensure that the rivet can be formed smoothly without loosening. For example:

- For the connection of aluminum plates with a thickness of 3–4 mm, the 4.8 mm (3/16″) closed-type rivets can be selected;

- For thicker structural plates (such as the bottom of a ship or a support), it is recommended to use 6.4 mm (1/4″) structural closed rivets to achieve higher shear strength.

Rivmate recommends using the models with Multi-Grip to reduce inventory and installation errors.

Q2: Are stainless steel rivets safe for aluminum hulls?

Not completely safe. Although stainless steel closed-type rivets (such as type 316) have excellent anti-corrosion properties, Galvanic Corrosion may occur when in contact with aluminum. If stainless steel rivets must be used on an aluminum vessel, insulating gaskets (EPDM, nylon, or anti-corrosion coatings) should be installed between the contact surfaces.

Q3: How do I waterproof rivets on my aluminum boat?

The key to achieving waterproofing is to use Closed End Rivets and follow the correct installation procedures. Before installation, it is necessary to apply waterproof sealant (Marine Sealant) or corrosion inhibitor at the hole opening; after the rivets are installed, the closed cavity at the tail end will completely prevent water from penetrating, thus forming a permanent seal. Compared to ordinary open rivets, the closed design significantly improves waterproof performance and reduces the need for long-term maintenance.

Q4: Can closed end rivets replace welding on small boats?

In certain structures, closed-type rivets can indeed replace welding. For small aluminum boats (Jon Boats, fishing boats, lightweight hulls), the use of closed-type structural rivets can achieve a fastening effect with strength comparable to that of welding. The advantages include:

- One-sided installation makes construction easier;

- No need for high-temperature operation, which will not damage the aluminum structure;

- Waterproof, shockproof and maintenance-free.

However, for the main structural parts that are subjected to high impact or stretching loads, it is still recommended to use them in conjunction with welding or reinforcement components.

Ensure Lasting Strength and Sealing with Rivmate Closed End Rivets

Closed End Rivets for Aluminum Boat has been proven to be the most reliable and cost-effective waterproof fastening solution. It not only achieves a complete seal to prevent water and salt spray from entering, but also maintains excellent shear and tensile strength in high-vibration and high-humidity marine environments. Compared to welding and bolt connections, the closed-end rivet structure is lightweight, easy to install, requires no maintenance, and is particularly suitable for the structural assembly and long-term use of small and medium-sized vessels.

Rivmate has over ten years of experience in marine fastening technology, specializing in providing high-strength, corrosion-resistant marine riveting solutions for shipyards, maintenance technicians, and individual boat owners. Our products comply with the ASTM B117 salt spray test standard and the ABYC H-1 hull fastening specification, ensuring that each rivet can maintain stable performance in the most demanding marine environments.

👉 Click here to visit [Rivmate Marine Fastening Center]

Explore the complete Closed End Rivets for Aluminum Boats, installation tools and anti-corrosion solutions. Keep your aluminum boat waterproof, safe and reliable for every voyage in the future.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met