Table of Contents

There are many types of blind rivets, and there may be questions about multi grip pop rivets vs exploding pop rivets. This comprehensive guide will give you a detailed overview of the differences between multi grip pop rivets vs exploding pop rivets.

But before we look at multi grip pop rivets vs exploding pop rivets, we need to briefly understand a little bit about multi grip pop rivets and exploding pop rivets.

Table of Contents

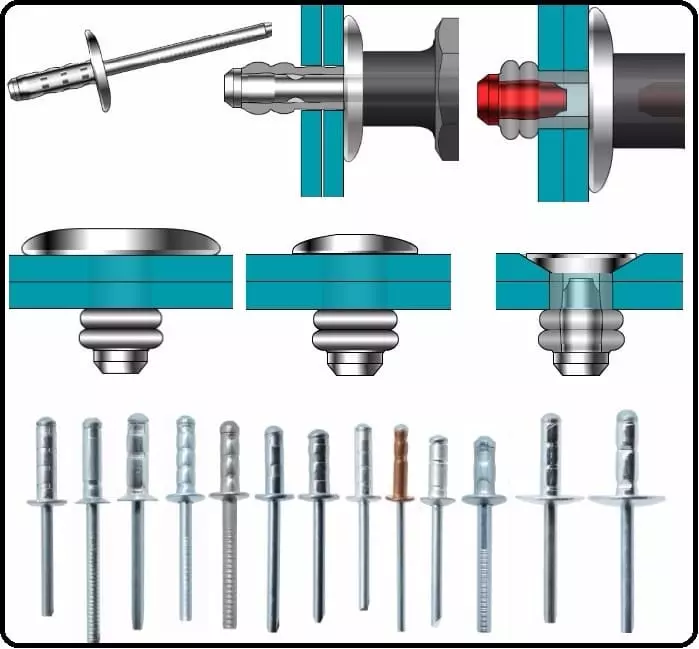

Multi-Grip Blind Rivets are specialty blind rivets with a wide riveting range. It requires only one size to accommodate material combinations of different thicknesses.

Multi grip pop rivets provide reliable clamping force through uniform deformation of the tail, making them ideal for joining multiple layers or dissimilar materials. And its installation is very simple and efficient, especially suitable for scenarios that require flexibility and reduced stock specifications. Because of their good tensile and shear resistance and protection of materials, multi grip pop rivets are widely used in automotive, aerospace, electronic equipment, industrial assembly and construction engineering.

Pros and Cons of Multi Grip Pop Rivets

As one of the most commonly used types of blind rivets, multi grip pop rivets offer many advantages and disadvantages that other rivets do not. A good understanding of multi grip pop rivets can help you better enhance your business.

Pros of Multi Grip Pop Rivets

- Wide riveting range: one model can cover a wide range of material thicknesses (e.g. 3-6mm or 6-9mm). This results in fewer rivets in stock and lower overhead costs. It also improves installation flexibility to accommodate changes in material thickness.

- High clamping force: Multi grip pop rivets can provide reliable tensile strength and rivet shear resistance.

- Reduced installation errors: eliminating the need to precisely match material thicknesses, Multi grip pop rivets will have far fewer failures due to thickness errors during installation.

- Material Friendly: Multi grip pop rivets provide uniform pressure distribution and reliable tail deflection. It is very friendly to riveting thin materials!

Cons of Multi Grip Pop Rivets

- Multi grip pop rivets have a higher unit price compared to standard blind rivets. This is because of its more significant manufacturing complexity and functionality enhancements.

- Limited application scenarios: Multi grip pop rivets are ideally suited for applications with medium strength requirements. However, it has limited performance in high dynamic loads, very high strength or extreme environments. It may not meet the needs of certain industrial equipment or high stress scenarios.

Main Applications of Multi Grip Pop Rivets

Multi grip pop rivets are widely used in several scenarios as one of the best selling type of blind rivets. It covers automotive, aviation, construction, electronic equipment, furniture, rail transportation and so on. Especially suitable for use on products that meet the following conditions:

- Different thickness or material combination.

- Multi-layer material splicing.

- Single-sided installation of closed structures.

- Reliable connections under dynamic loads.

Multi grip pop rivets offer efficient and stable solutions in a wide range of complex conditions thanks to their wide grip range and high adaptability. The following are common application components and parts:

- Automotive industry: fixing of plastic decorative parts in cars and assembly of battery housings for electric vehicles.

- Aerospace: fixing of interior panels and lightweight brackets.

- Construction: assembly of window and door frames.

- Industrial equipment: assembly of sheet metal housings and frames for industrial equipment.

- Light structures: assembly of billboards and connection of artifacts to decorative materials.

What are Exploding Pop Rivets?

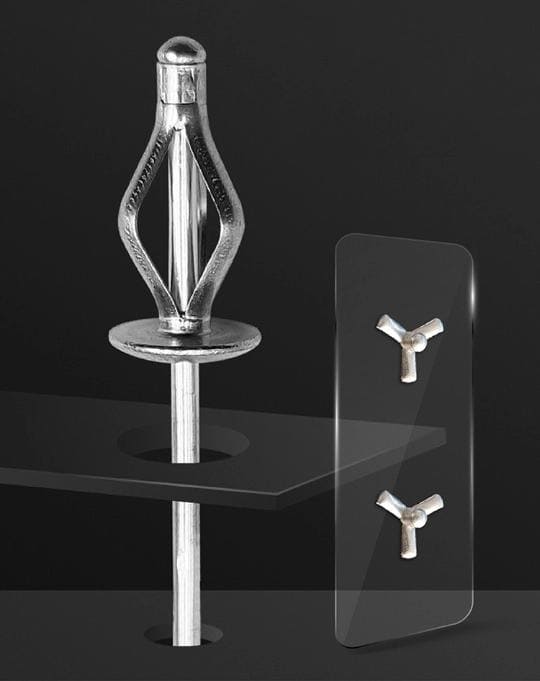

Exploding pop rivets are a special design of blind rivets. When installed, exploding pop rivets have multiple “petal” shapes that unfold at the end of the rivet to provide a larger clamping area and greater fixing stability.

Exploding pop rivets are ideal for joining soft materials (e.g., plastics, fiberglass, wood) or thin-walled materials to avoid possible pull-through or deformation problems.

Pros and Cons of Exploding Pop Rivets

Exploding pop rivets are structural rivets that are very difficult to produce. It is made of aluminum, which provides excellent corrosion resistance and performs well in lightweight applications.Exploding pop rivets with rubber gaskets provide excellent water resistance. Below are some of its main advantages and disadvantages.

Pros of Exlpoding Pop Rivets

- Suitable for soft or brittle materials: such as plastic, fiberglass, wood, etc., to avoid material breakage or pull through.

- Large contact area: The “petal” shape of the tail provides a larger contact area and evenly distributes the pressure.

- Versatility: Can connect a variety of material combinations, such as metal and plastic, plastic and wood, etc.

- Waterproof: When used in conjunction with a gasket, exploding pop rivets provide excellent waterproofing.

Cons of Exploding Pop Rivets

- Limited strength: Not suitable for high strength or high dynamic load applications.

- High requirements for hole accuracy: too large a hole may result in uneven tail spread, too small a hole may prevent rivet insertion.

- Slightly higher cost: Compared with ordinary blind rivets, the manufacturing process is more complicated and the unit price is higher.

Main Applications of Exploding Pop Rivets

Exploding pop rivets are a type of blind rivet optimized for soft materials and lightweight applications. And when paired with a waterproof gasket, they provide excellent waterproofing.

- Furniture manufacturing: fixing of wood to metal frames, reinforcing connections at splicing points in wooden furniture.

- Automotive industry: fixing of interior parts (e.g. plastic panels, armrest installation).

- Building decoration: curtain wall fixing (fiberglass panels or decorative panels).

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Multi Grip Pop Rivets vs Exploding Pop Rivets

Multi grip pop rivets and exploding pop rivets are both part of the same group of rivets. While they can both provide a stable connection to thin plates, there are some differences in the scenarios and conditions of use. Here are the main differences between multi grip pop rivets vs exploding pop rivets.

| Feature | Multi-Grip Pop Rivets | Exploding Pop Rivets |

| Tail Expansion | Simple expansion to adapt to various thicknesses. | Splits into “petals,” creating a larger contact area. |

| Grip Range | Wide grip range, suitable for multiple material thicknesses. | Fixed grip range, requires precise thickness matching. |

| Material Compatibility | Suitable for metals, plastics, and composites. | Best for soft or brittle materials like plastic, wood, or fiberglass. |

| Clamping Force | High, suitable for multi-layer or mixed materials. | Moderate, focuses on distributing pressure to prevent material damage. |

| Tensile Strength | High, supports medium to heavy-duty applications. | Moderate, suitable for lightweight applications. |

| Shear Strength | High, suitable for dynamic loads or vibration. | Moderate, less effective in dynamic load scenarios. |

| Material Protection | Protects thin materials with uniform pressure distribution. | Prevents pull-through or cracking in soft or brittle materials. |

| Typical Applications | Automotive frames, industrial enclosures, building facades. | Furniture assembly, plastic enclosures, decorative panels, wood joints. |

| Dynamic Load Suitability | Suitable for vibration and high dynamic loads. | Not recommended for high dynamic loads; better for static applications. |

| Hole Precision Requirement | Tolerant to slight mismatches in hole size. | Requires precise hole size and alignment for proper installation. |

| Cost | Higher due to functionality and versatility. | Lower for lightweight, specific applications. |

Order High Quality Multi Grip Pop Rivets or Exploding Pop Rivets

As a business owner, you need to know clearly the difference between multi grip pop rivets vs exploding pop rivets. This way you can choose the most effective riveting solution for your business.

If you are looking for reliable multi grip pop rivets or exploding pop rivets for your project, contact us! Rivmate is a blind rivets manufacturer of IATF 16949.

Get rivet samples for testing today!