Table of Contents

For composites, the question of how to install them without damaging the material is a matter of concern, and Riveting offers an excellent solution.Riveting composites material allows for stable connections without damaging the surface of the material.

By reading this article, you will learn about the method of riveting composites, how to select rivets and practical applications.

Table of Contents

Characteristics of composite materials and riveting risks

Composite materials are widely used in structural systems such as aerospace, automotive, photovoltaic, and electrical enclosures due to their lightweight, high strength, and design flexibility. However, compared to metal materials, composite materials present a series of unique risks during riveting. If not handled properly, these risks can not only affect the strength of the connection but also lead to structural failure or even safety hazards. The main riveting risks are as follows:

- Layered structure prone to delamination failure

- Anisotropic mechanical properties leading to uneven load distribution

- Drilling prone to thermal burning and fiber tearing

- Electrochemical corrosion when in contact with metal rivets

- Thermal expansion mismatch causing fatigue cracks

Although composite materials offer structural advantages, their laminate characteristics, thermomechanical behavior, electrochemical stability, and processing sensitivity must be comprehensively considered during riveting. Rivmate provides a complete riveting product solution and engineering expertise for composite material connections. Through structural optimization, material matching, and assembly process control, we effectively mitigate the aforementioned risks to achieve safe, stable, and durable fastening connections.

Why can't traditional rivets be used with composite materials?

Traditional rivet designs are primarily based on the connection requirements of metallic materials, such as steel plates, aluminum plates, and stainless steel plates—all homogeneous materials. However, when such rivets are directly applied to composite materials (such as carbon fiber, glass fiber, SMC/BMC, etc.), they often result in structural damage, connection failure, or a significant reduction in service life. The core reason lies in the mismatch between the structural expansion force and point loading characteristics of traditional rivets and the physical response of composite materials.

While traditional rivets are simple in structure and cost-effective, they exhibit significant shortcomings in mechanical compatibility, electrochemical compatibility, and structural support methods when applied to composite materials—non-metallic heterogeneous structures. Direct use may trigger irreversible damage:

- Panel bulging/collapse

- Interlaminar delamination/microcrack propagation

- Core shaft slippage/corrosion pitting

- Insufficient overall structural rigidity after installation

Therefore, composite materials should use specially optimized composite-specific rivets. These rivets feature a large cap surface with low stress distribution, corrosion resistance, flexible mandrels, and expansion control, enabling truly safe, stable, and long-lasting mechanical connections.

Rivmate offers multiple series of composite-specific rivet products, which are widely used in new energy, aerospace lightweight structures, and rail transit composite components.

What are the methods of riveting composites?

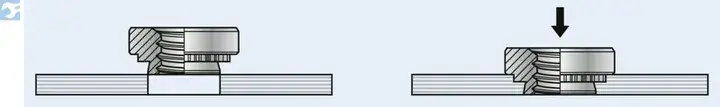

Self Clinching Fastener

Self clinching fastener is embedded in the composite material by pressure or impact. It is suitable for hybrid joining of metals and composites. However, incorrect use may result in delamination of the composite or fiber breakage.

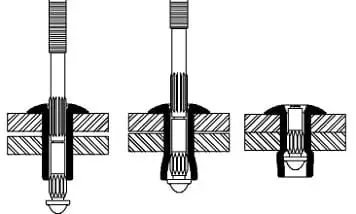

Riveting

riveting is the mechanical deformation of rivets by tension to form a stable connection. Rivets can join many different composite and metallic materials. However, before using rivets, holes need to be drilled in advance. A large number of rivets are used in aircraft skins.

However, excessive riveting force can cause damage around the hole, so it is necessary to closely control the hole diameter (deviation ≤ 0.1mm) and riveting force.

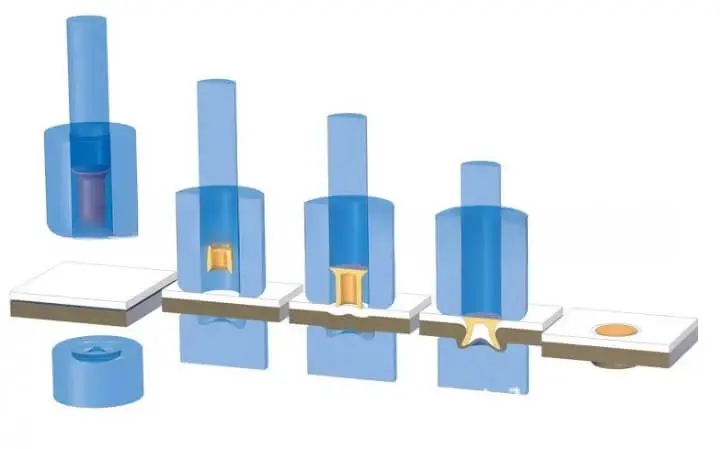

Self Piercing riveting

The use of self piercing riveting eliminates the need for pre-drilled holes, directly penetrating the material and riveting it with punching force.

Self piercing rivets are mainly used for short fiber composites or thermoplastic basic composites. Its advantages include reduced hole damage and high joining efficiency.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Choose Rivets for Composites?

I. Rivet material selection

Common riveting materials for riveting composites are listed below:

- Titanium alloy: Aircraft skins, hatches and other parts that require high lightweight and fatigue resistance.

- Aluminum: low cost and light weight. Corrosion resistance and can be riveted to carbon brazing.

- Nickel: suitable for riveting composite materials in high temperature environment.

Ⅱ. rivet structure type

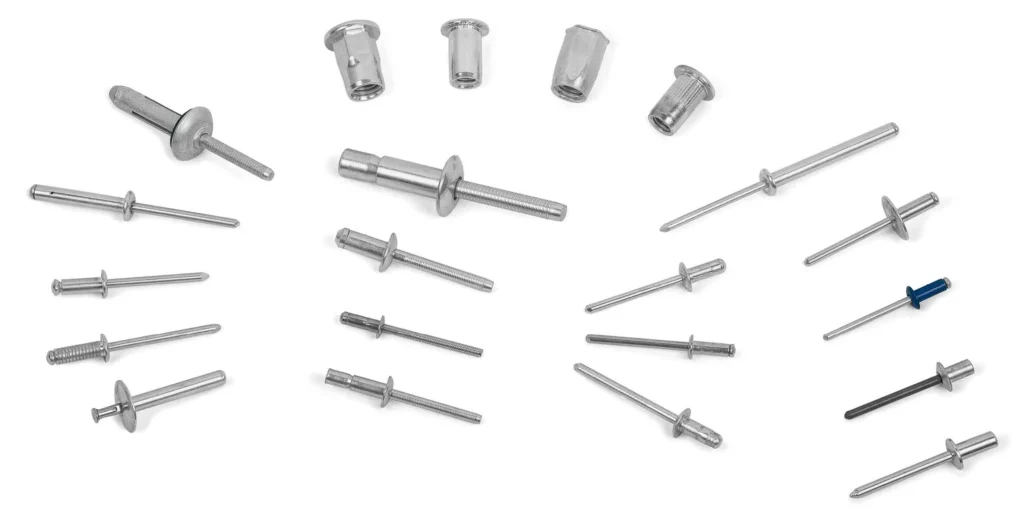

Blind Rivets: Its structure is characterized by the expansion of the tail to form a latch, suitable for unilateral operation. When riveting composite materials, you can choose titanium alloy or 5056 aluminum alloy, lightweight and tensile strength ≥ 500MPa. It is used more in the UAV fuselage, small-size composite parts connection.

Break Stem Rivets: The rivet mandrel breaks during riveting to form a high tensile strength connection. This type of rivet is very suitable for riveting high yield strength composite materials (such as IM7 carbon fiber / epoxy resin).

Shear-Type Rivets: Flat or countersunk head design, preferentially subjected to shear loads, used to join composites to metal laminations.

Ⅲ. rivet optimization design key technology

Surface Finishes

- Anti-corrosion coatings: Titanium rivets can be aluminized or coated with PTFE to block galvanic coupling corrosion with carbon fibers.

- Lubrication and drag reduction: Manganese Phosphate coating reduces the frictional drag of the riveted joint (coefficient of friction reduced by 30%).

Coupling shape optimization

- Streamlined rivet head: reduces aerodynamic drag (for exposed aircraft connections).

- Distributed grooves: promote uniform rivet expansion (especially for thick plywood).

Lightweighting program

- Honeycomb core rivets: internal honeycomb structure reduces weight by 15%~20%, strength loss ≤5%.

- Variable cross-section design: localized thickening of connecting segments to improve tensile/shear performance.

Do You Have Any Questions?

Let Us Solve Your Problem

Applications of Riveting Composites

There are numerous examples of riveted composites being used in aerospace and automotive manufacturing, where the core of the technology is to achieve lightweight, high-strength connections through optimized processes.

Aerospace

Riveting can provide significant weight savings and stable connections for aerospace.

- Aircraft fuselage and wings (Airbus A350/A380): Carbon Fiber Reinforced Composite (CFRP) + Titanium skeleton.

- Spacecraft Fuel Tank (SpaceX Starship): Carbon Fiber/Epoxy Composite + Inconel Alloy Liner.

- UAV structure (MQ-9 Reaper): carbon fiber/epoxy skin with aluminum honeycomb core riveted on one side.

Automotive Manufacturing

- All-aluminum body (Audi A8/A6 e-tron): self-pierce riveted (SPR) + glued. Body torsional stiffness increased by 25%, 15% weight reduction in white body.

- New energy vehicle battery box (Tesla Model Y): automated self-pierce riveting robot. Avoid welding heat affected zone (HAZ), vibration resistance improved by 30%.

- Steel-aluminum hybrid body (Ford F-150 Lightning): high-strength steel rivets. Reduced processes, steel-aluminum connection strength up to 1.5 times that of conventional welding.

Custom Riveting Solutions for Composites Project

During composite material riveting, even if suitable specialized rivets are selected, improper installation or neglect of critical process details may still lead to structural hazards or performance degradation. The following are common installation issues and troubleshooting tips for composite material riveting.

- Asymmetric rivet deformation / off-center riveting: Use a positioning die to ensure drilling and assembly alignment. Adjust the riveting gun direction to ensure vertical force application. Control hole diameter tolerance within the recommended range (typically rivet diameter +0.1mm).

- Panel bulging / abnormal appearance: Prioritize the use of large-head, low-expansion rivets (e.g., Bulb-Tite, Tri-Fold). Alternatively, install specialized riveting washers on the back side.

- Insufficient tensile strength / loose rivet grip: Select the appropriate clamping range specification based on the total plate thickness.

- Exposed or fallen core shaft after riveting: Switch to a closed-type rivet structure to prevent core shaft penetration.

Composite material riveting is not the same as metal riveting; the installation process must be optimized according to the material properties. Structural optimization-type specialized rivets should be used as a priority to avoid structures with high expansion and high concentrated forces. Drilling and riveting process parameters must also be strictly controlled. It is recommended that 2–5 samples be tested before each batch of riveting to ensure system consistency.

Rivmate provides specialized rivet installation guidance for composite materials, on-site technical support, and equipment compatibility recommendations to help customers systematically improve riveting quality.

FAQs

Q1: Can composite materials be connected with rivets? Is it reliable?

A1: Yes, but rivets specifically designed for composite materials (such as three-piece blind rivets, Bulb-Tite, etc.) must be used. As long as the type is selected and operated properly, the reliability of riveting on composite materials can meet long-term structural requirements.

Q2: Can ordinary aluminum rivets be used on carbon fiber plates or fiberglass plates?

A2: Not recommended. Ordinary rivets have high expansion force, which can easily cause delamination, local tearing, or instability of the panel surface, especially in thin panels and sandwich structures where the risk is higher. Special rivet products with low tensile force, large cap surface, and flexible expansion design should be selected.

Q3: Does Rivmate offer specialized rivet products for composite materials?

A3: Yes. Rivmate offers a range of composite-specific rivets designed specifically for materials such as carbon fiber, glass fiber, SMC/BMC, and more. These include closed blind rivets, three-piece large-surface pressure structures, and dual-clamping structure rivets. In addition, we provide custom design services based on drawings, bulk sampling, and structural optimization consulting services.

Custom Riveting Solutions for Composites Project

Composites can provide high strength, light weight, wear and temperature resistance, but how to safely rivet composites has become a challenge. Composites are very susceptible to fiber tearing and delamination around the hole when drilling, and riveting technology, which does not require pre-drilling, is the perfect solution to this problem.

If looking for a reliable rivet supplier for your composite project, contact us!Rivmate is the leading rivet manufacturer and supplier for professional riveting solutions.

Get samples for testing today!