Table of Contents

Rivet guns are the most commonly used riveting tools. So know how to use a rivet gun? This guide will explain you in detail through 10 steps.

Table of Contents

Why Use Pneumatic Pop Rivet Guns?

There are several advantages to using a Pneumatic Pop Rivet Gun over other joining tools, especially in industrial or construction environments where efficient, accurate and high volume riveting is required.

- Increased Productivity: Pneumatic Pop Rivet Guns use compressed air to power the rivets, which can significantly speed up the riveting process. Reduce the time spent on manual riveting. And after the riveting is completed, the core bar of the rivet will be automatically disconnected, and the waste collection device inside the rivet gun can also automatically dispose of the core bar debris.

- Reduce labor intensity: Compared with manual rivet guns, pneumatic rivet guns greatly reduce the manual operation of physical exertion.

- Ensure the consistency of riveting: pneumatic rivet gun each time the riveting force is relatively consistent, to avoid the human factor caused by the difference in riveting strength.

- Suitable for large-scale industrial production: Pneumatic core-pulling rivet gun is particularly suitable for assembly line operations, such as automobile manufacturing, aircraft assembly, home appliance manufacturing and other industries in the high-volume riveting tasks. It can complete a large number of rivets in a short period of time.

- Easy to operate: pneumatic rivet gun is easy to operate, workers can quickly get started without complex training.

How to Use a Rive Gun: 10 Steps

Pneumatic rivet guns are the most used riveting tools in industry. When using a pneumatic rivet gun, it is important to ensure that it is operated correctly and safely. Ensure the consistency of riveting quality. The following are detailed steps for using a pneumatic rivet gun.

1. Check Equipment and Prepare Tools

Before using the pneumatic rivet guns, the operator needs to carefully check the various components of the pneumatic rivet gun. You need to make sure that the gun nozzle, jaws, pneumatic interface is not damaged, and that there are no signs of air leakage from the gas source interface.

If the rivet gun is fine, the next step is to choose the right blind rivets. We need to be riveted according to the thickness, strength and connection needs of the material, select the appropriate rivet type, rivet size and rivet material (such as aluminum, stainless steel, carbon steel, etc.).

2. Preparation for Drilling

Before formal drilling, you need to know what size drill bit for rivets?When you drill a hole in the material to be riveted, the hole diameter should be slightly larger than the rivet’s diameter, usually 0.1-0.2 millimeters larger than the rivet’s diameter, so as to ensure that the rivet can pass through the hole smoothly. Of course, if the hole is too small, it may cause the rivet to fail.

After drilling the hole, there will be a lot of burrs and iron chips around the hole. To ensure a good riveting result, you need to clean the hole. Clean the burrs and debris around the holes and make sure the edges of the holes are smooth, so that you can avoid damage to the material or poor riveting.

3. Connect the Air Source

There are three common power sources for rivet guns: human powered, electric powered, and pneumatic powered. And pneumatic rivet guns are powered by compressed air. When in use, the operator connects the pneumatic rivet gun to the air compressor to ensure that the air source pressure meets the requirements of the rivet gun (usually the air pressure is 6-7 bar, about 90-100 PSI). Use pneumatic hose to connect the compressor and check the sealing of the air source connector to make sure there is no air leakage.

4. Calibrate the Gun Nozzle

For better riveting, you need to choose a snub nose that matches the size of the rivet. The operator needs to check that the nozzle of the rivet gun matches the diameter of the rivets, and if the nozzle needs to be replaced or adjusted, make sure that the nozzle selected properly clamps the rivet mandrel. Make sure the nozzle is the proper size to prevent the rivet from jamming or failing to clamp.

5. Inserting the Rivet

o far, we have completed the pre-preparation for installing rivets. The next step is to insert the mandrel of the rivet into the nozzle of the rivet gun and make sure that the rivet cap is correctly placed in the hole of the material to be connected.

The rivet is then properly aligned with the material to be riveted. The nail cap of the rivet should be tightly pressed against the surface of the material, with the mandrel fully inserted into the hole in the material.

6. Press the Trigger to Rivet

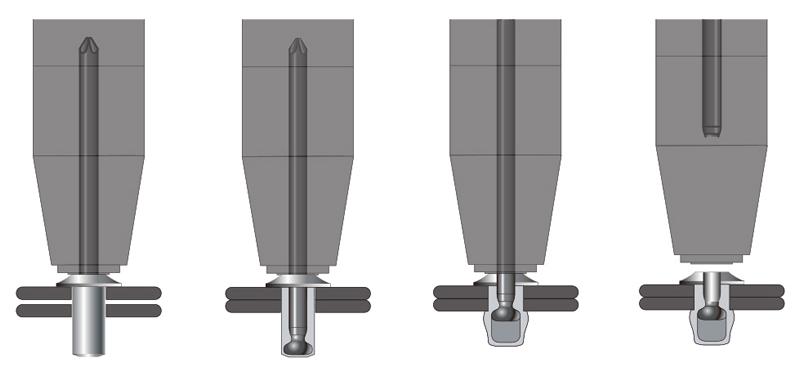

By gently pressing the trigger of the rivet gun, compressed air enters the air chamber of the rivet gun and drives a piston that pulls the core bar of the rivet tight. As the mandrel pulls back, the end of the rivet begins to expand, forming an expanding head.

Blind rivets continue to tighten as the mandrel continues to pull, and the tail end of the rivet fully expands, firmly holding the material together. When the proper tension is reached, the rivet mandrel automatically breaks at the predetermined break point.

7. Release Trigger

When the rivet mandrel breaks and the riveting is complete, release the trigger on the rivet gun. At this point, the piston of the pneumatic rivet gun will automatically reset, ready for the next riveting operation.

8. Checking the Quality of the Riveted Joint

After completing the installation process of pop rivets, in order to ensure excellent riveting results. The operator needs to perform a brief inspection of the riveted joint. Mainly check the following aspects:

- That the cap of the rivet is tight against the surface of the material.

- Whether the tail end of the rivet expands well

- whether the connection is firm and not loose

If it is found that the riveting is poor or the rivets are not fully secured, the operator needs to re-punch and rivet to ensure the quality of the connection.

9. Handling of Waste Materials

The mandrel of a rivet will break when the rivet gun is used to finish riveting a blind rivet. When a rivet’s mandrel breaks, it is usually collected by the rivet gun’s waste collection system. If your rivet gun does not have an automatic collection device, this will require you to manually clean up the work area to ensure that the broken rods are not strewn about the job site to prevent a safety hazard.

10. Finish the Job and Store Tools

After using the pneumatic rivet gun, you should take care of it. After completing the riveting task, the operator needs to turn off the pneumatic system and disconnect the rivet gun from the compressed air. When storing, make sure the rivet gun’s hose and air connections are dry and undamaged.

In addition to this, the cleaning and maintenance of the rivet gun is also very important. You can use a dry cloth or air pressure gun to clean the rivet gun, especially the nozzle, jaws and pneumatic connections to avoid clogging with dust or debris. If necessary, the O-rings, seals and other wear parts of the rivet gun can be checked regularly to ensure the proper operation of the tool.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

FAQs

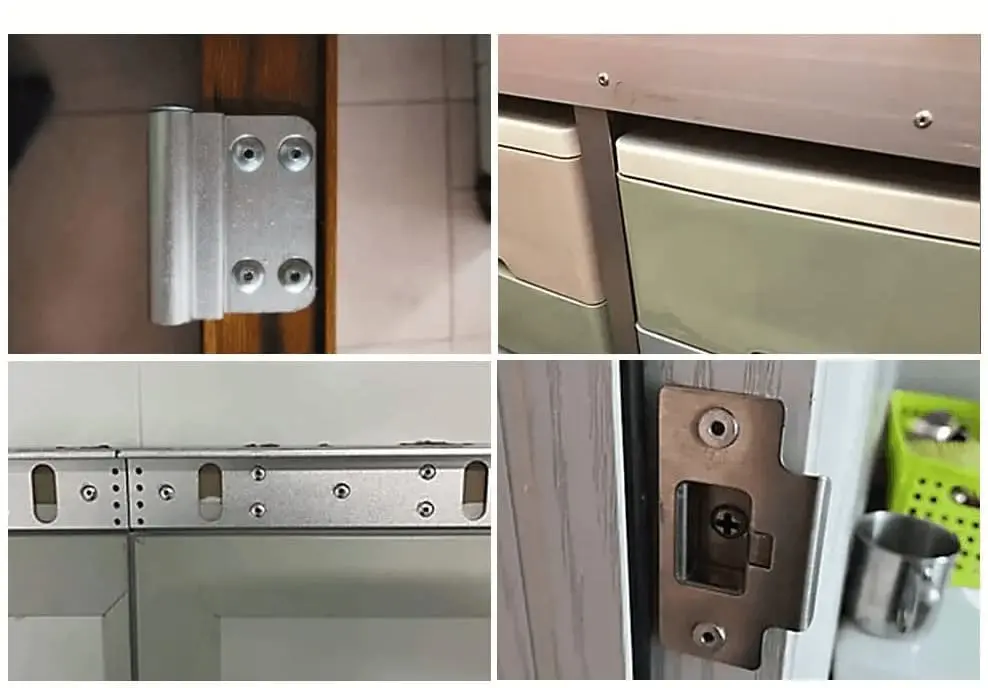

What Application Scenarios are Pneumatic Rivet Guns Suitable for?

Pneumatic rivet gun is widely used in industrial production, construction engineering, automobile manufacturing, aerospace, home appliance assembly and other fields. In occasions where a large number of rivets or high-strength rivets are required, the pneumatic rivet gun is the best choice. It is especially suitable for riveting metals, plastics and composites where efficient and stable riveting is required.

Can the pneumatic rivet gun adjust the riveting force?

Some pneumatic rivet guns can be used to adjust the riveting force by adjusting the pressure of the air source. By adjusting the air pressure, it can be adapted to different materials and rivets to ensure that the expanding head of the rivet is well formed and does not unduly damage the material.

How long does a rivet gun last?

The life of a rivet gun depends on the frequency of use, maintenance and the working environment. Regular maintenance, such as lubrication and replacement of wear parts, can extend the life of a rivet gun. For most industrial grade tools, the life expectancy can be several years if they are properly maintained.

OEM Pneumatic Pop Rivet Guns for Your Project

Rivmate is the top pneumatic pop rivet gun manufacturer in China.If you need to buy high quality pneumatic rivet gun, please contact us.

We offer Rivmate pneumatic rivet gun. Besides that, our factory also provides OEM service. If you want to publicize your brand with lower cost, please contact our engineers!