Table of Contents

The blind rivet tensile strength is an indicator that business owners need to keep an eye on. This ensures that your project is in safe hands.Let’s explore!

Table of Contents

What is the Blind Rivet Tensile Strength?

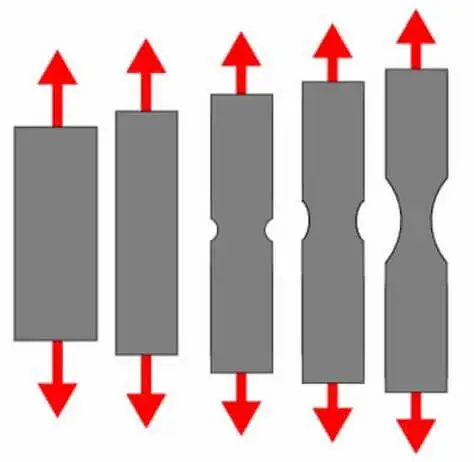

Tensile Strength is the maximum stress at which a material will resist fracture under tensile force. For blind rivets, this parameter indicates the maximum load that the rivet can withstand when a tensile force is applied, and is usually expressed in megapascals (MPa) or pound force (lbf).

Blind Rivet Tensile Strength is a measure of the ability of a blind rivet to resist tensile stress in its axial direction when joining two pieces of material.

For blind rivet, shear strength and tensile strength are the two most important strength indicators. Qualified tensile strength ensures that the blind rivet will maintain the stability of the connection in practical applications. When business owners buy blind rivets, they basically pay attention to the index of tensile strength.

Factors Affecting the Blind Rivet Tensile Strength

Blind rivet tensile strength is used as one of the important indicators for blind rivets. It is influenced by a number of factors that determine the maximum tensile force that the rivet can withstand in practice. The following are the key factors affecting the blind rivet tensile strength:

1.Material

There are many types of materials used to manufacture blind rivets. Different materials have different inherent strength properties. For example, stainless steel has high tensile strength, while aluminum is lighter but less strong. Monel (nickel-copper alloy) combines high strength with excellent corrosion resistance.

In addition to this, the tensile strength of different grades of the same material (e.g. different contents of carbon steel or different types of stainless steel) can vary significantly.

In general, a larger rivet diameter usually means higher tensile strength. This is because the larger the rivet diameter the more tensile force it can withstand. Smaller diameter rivets are more likely to break under the same amount of tension.

3.Rivet Design

Blind rivets are available in three head types: countersunk head, large flange head and round head. Different rivet head designs affect the distribution of forces in the material, which in turn affects the tensile strength of the rivet. Large flange head can better distribute stresses and reduce material deformation, which helps to improve the overall tensile strength.

4. Material Thickness

The tensile strength of blind rivets may be compromised when used in materials that are too thick or too thin. Excessively thick materials may not lock completely, while excessively thin materials may be pulled through or deformed, affecting the reliability of the connection.

5. Surface Treatment

Anti-corrosion coatings: Materials that are susceptible to corrosion, such as carbon steel, are often given a surface treatment (e.g., galvanized or coated). This improves their corrosion resistance and tensile strength. However, improper surface treatment may cause the coating to peel off or the rivet to corrode, reducing tensile strength.

Anodizing: Aluminum rivets are often anodized to increase their surface hardness and corrosion resistance, which indirectly increases tensile strength.

6. Fatigue and Aging

Blind rivets are subjected to repeated tensile stresses and their tensile strength gradually decreases. Microscopic cracks caused by fatigue may eventually cause the rivet to break.

Over time, certain materials (e.g., plastics or certain metals) may deteriorate. This is resulting in a reduction in the tensile strength of the blind rivet.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Test Methods for Blind Rivet Tensile Strength

Rivmate’s Blind Rivets are tested for tensile strength in accordance with international standards such as ASTM F606/F606M and ISO 14589. These two standards are internationally recognized standards for rivet testing.

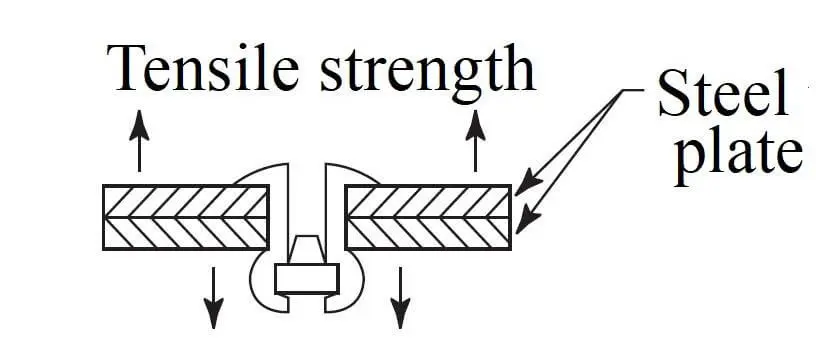

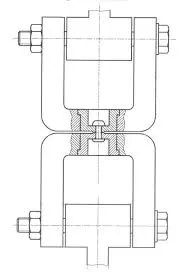

General testing of blind rivet tensile strength requires the use of a tensile testing machine and fixtures. This equipment is capable of applying and accurately measuring the maximum tensile strength of a blind rivet before it breaks.

Below are the steps to test the blind rivet tensile strength:

- Installation of blind rivets to be tested into the fixture

- Start the tensile tester and apply the tensile force slowly and evenly. The speed of application should be in accordance with standard specifications.

- A tensile tester will record the maximum tensile force, or tensile strength, at which a rivet breaks. Record the relevant data.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

How to Choose the Right Blind Rivet?

1.Material Selection Based on Tensile Strength

The difference in tensile strength of different materials is significant. Therefore choosing the right material can have a direct impact on the strength and durability of the connection. The strength requirements of most projects can be categorized into the following two types:

- High Tensile Strength Requirements

- Medium Tensile Strength Requirements

Typically projects with high tensile strength requirements will choose higher strength materials. For example, stainless steel blind rivets, carbon steel blind rivets and monel blind rivets. These material types are perfect for providing a stable and secure connection for high strength applications.

Projects with medium tensile strength requirements include electrical connections and lightweight design projects. Such projects typically use aluminum rivets with a good strength-to-weight ratio and copper rivets with good electrical conductivity.

2. Selection of Blind Rivets According to the Actual Application

In actual use, many projects have very strict requirements for blind rivet tensile strength. For example, in construction and structural engineering, blind rivets need to withstand external loads (e.g. wind, vibration, etc.). Then blind rivets need to have high tensile strength, so as to ensure the safety and stability of the structure.

Typical applications for medium tensile strength include the connection of electrical equipment and electronics. These applications do not require high strength, but they do require specific properties of the blind rivet. For example, light weight or extremely high electrical conductivity.

Frequently Asked Questions

1.Why is the Blind Rivet Tensile Strength Important?

Blind rivet tensile strength determines the ability of the rivet to maintain the integrity of the connection when subjected to external forces. In applications where high tensile forces need to be resisted, choosing the right blind rivet tensile strength can prevent joint failure or structural damage.

2.What Applications Require Special Attention to the Tensile Strength of Blind Rivets?

Tensile strength is a factor that must be given special attention when selecting blind rivets for applications such as building structures, aerospace, bridges, heavy machinery and other applications where high stresses and tensile forces need to be applied.

3. What is the Difference Between the Tensile and Shear Strength of Blind Rivets?

Tensile strength measures the ability of a rivet to resist the action of a tensile force. Shear strength, on the other hand, measures the ability of a rivet to resist a shear force, such as two pieces of material sliding against each other. Both parameters are critical for different types of loads.

Conclusion

Blind rivet tensile strength is an important metric for manufacturers to consider when selecting a blind rivet. A blind rivet with the proper tensile strength will ensure that the connections in your project are stable and secure. This will minimize subsequent repairs and result in significant cost savings.

With this guide, I’m sure you’ve got a primer on blind rivet tensile strength. Please carefully evaluate the tensile strength of blind rivets before purchasing blind rivets for your project. if you need help, please contact our engineers.

Order Right Tensile Strength Blind Rivets for You

Rivmate is not only a reliable pop rivet manufacturer, but also a professional rivet customization solution provider. Any technical questions and ordering problems regarding pop rivets, Rivmate can solve them for you.

Order high quality blind rivets in bulk and get a quote for rivets today.