Table of Contents

Rivets are generally used to join thin sheet products. So do you know HOW to choose rivets for thick material?

By reading this blog, you will get to know the points to look out for rivets for thick material.

Table of Contents

Why Use Rivets for Thick Material?

If you look closely, you’ll notice that there are more and more applications using rivets these days. Rivets connect thick materials are widely used in industry, construction, transportation and other fields. Its core advantages are reflected in strength, reliability, installation flexibility and adaptability.

- High strength and fatigue resistance

- Single-sided installation

- Wide material compatibility

- Low cost

- Lightweight Advantage

Typical applications of rivets in joining thick materials are as follows:

- Heavy machinery: excavator boom (thick steel plate) using structural rivets to resist shear.

- Aerospace: aircraft wing skin and skeleton with titanium alloy rivets to reduce weight and fatigue.

- Shipbuilding: thick steel plate riveted hull corrosion and seawater impact resistance.

Cautions

- Thickness Limit: Ordinary blind rivets are suitable for ≤25mm, thicker materials need solid rivets or a combination of solutions.

- Professional selection: according to the load, the environment to match the rivet material and type (refer to this article selection guide).

Types of Rivets for Thick Material

Not all rivets can be used to install thick materials. Below I will describe several rivets that are suitable for riveting thick materials.

Riveting thick materials generally requires rivets that can withstand high strength. Designed for high strength applications, structural rivets have excellent rivet shear strength and rivet tensile strength. However, the installation of structural rivets requires the use of a specialized pneumatic rivet gun.

Structural rivets are usually riveted to load-bearing areas. Applicable scenarios are as follows:

- Materials with a total thickness of 6-25 mm (e.g. steel structures, heavy machinery).

- Where dynamic loads are required (e.g. vehicle frames, bridges)

Multi grip blind rivets span a wide rivet grip range. This type of rivet can accommodate a wide range of material thicknesses (e.g. 3-13mm).Multi grip blind rivets can take the pressure off your inventory. Regardless of the thickness of the sheet material, the same size multi rivets can be used for riveting.

The applicable scenarios for Multi grip blind rivets are as follows:

- When you are not sure about the thickness of the material or when there are variations (e.g. sheet metal splicing, vehicle repairs).

- No need to accurately predict quantities, suitable for DIY or on-site work.

Blind Rivet Reinforced

To hold thicker materials in place, blind rivets can be used in larger sizes or steel core designs. This design of blind rivet provides higher holding power and shear strength to the backing material.

Applicable Scenarios:

- Single-sided operation, total thickness 5-12 mm (e.g. steel containers, industrial equipment).

- It is recommended to choose a steel core or stainless steel to increase the load capacity (e.g. Magna-Lok series).

Solid Rivets

Solid rivets are the most traditional rivets. Its installation requires a double-sided operation (knockout molding). Solid rivets are extremely reliable and are well suited for use on heavy-duty projects.

Today, solid rivets are used exclusively for riveting thick materials. Here are some of its application scenarios.

- Extremely thick materials (e.g. boilers, shipbuilding, aerospace).

- Permanent non-removable connections for static load dominated applications.

Do You Have Any Questions?

Let Us Solve Your Problem

How Thick of Material Can you Rivet?

The thickness of material that can be riveted to a rivet varies depending on the type, material and design. The following are common types of rivets and the range of material thicknesses they are suitable for.

- Standard blind rivets: aluminum blind rivets are suitable for riveting single-layer materials with a total thickness of 0.5-6mm. steel core/stainless steel blind rivets are suitable for riveting a total thickness of 1-12mm (higher strength, suitable for thicker materials).

- Structural rivets: single-layer material thickness of 6-25mm (such as steel structure, heavy machinery).

- Multi grip blind rivets: very wide range of coverage. 3-13mm (such as sheet metal splicing, vehicle frame).

- Solid Rivets: Theoretically capable of riveting very thick materials (e.g. boilers, ships with steel plates over 20mm).

- Monobolt rivets: thin to medium materials: 1-8mm (commonly used in electronic equipment, furniture).

How to Choose Rivets for Thick Material?

When selecting blind rivets for thick materials, it is important to consider the thickness of the material, strength requirements, installation conditions and environmental factors. The following are specific steps.

1. Measure the total thickness → 2. Select the type (multi-clamping/structure) → 3. Determine the material → 4. Match the diameter and length.

I. Specify the total thickness of the material

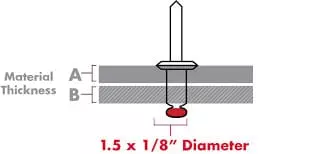

- Measure the total thickness: the material to be connected to the multi-layer superposition, measure the total thickness (eg: two 8mm steel plate superposition for 16mm).

- Reserve margin: the rivet “clamping range” should cover the total thickness, and leave a margin of about 1-2mm (eg: the total thickness of 10mm, choose the rivet clamping range of 8-12mm).

Ⅱ. select the type of blind rivets

Select the following types based on thickness and strength requirements:

- Multi grip blind rivets (Multi-Grip): for thicknesses from 3-13mm (e.g. metal frames, vehicle repairs).

- Structural Blind Rivets (High Strength Blind Rivets): For thickness 6-25mm (e.g. steel structures, bridges).

- Large Diameter Blind Rivets with Steel Core: For thickness 8-12mm (e.g. industrial equipment, cargo containers).

Ⅲ. determine the material

- Aluminum rivets: lightweight, corrosion-resistant, but lower strength, suitable for thickness ≤ 6mm non-load-bearing scenes.

- Steel core/stainless steel rivets: high strength and shear resistance, suitable for load-bearing structures with thickness ≥ 6mm.

Ⅳ. matching rivet diameter and length

1. Diameter Selection

The thicker the material to be riveted for your project, the larger the rivet diameter needs to be (common diameters: 3mm, 4mm, 5mm, 6mm). Specifically you can refer to the following rules:

- Thickness ≤ 6mm: choose 3-4mm diameter.

- Thickness 6-12mm: choose 4-5mm diameter.

- Thickness>12mm: choose ≥5mm diameter, or switch to structural rivets.

2. Length calculation

Rivet length ≈ total material thickness + the length required to form the head of the rivet (usually 1.5 times the diameter). Let’s take for example a material with a total thickness of 10mm to be riveted. For a 5mm diameter rivet, the length of the rivet would be ≥ 10mm + (5 x 1.5) = 17.5mm.

Do You Have Any Questions?

Let Us Solve Your Problem

Wholesale Rivets for Thick Material Project

Read through this guide and if you’re still not sure how to choose the right rivets for your THICK MATERIAL project, contact us!

Rivmate is leading rivet manufacturer in china. you will get professional riveting solution.

Get samples for testing now.