Table of Contents

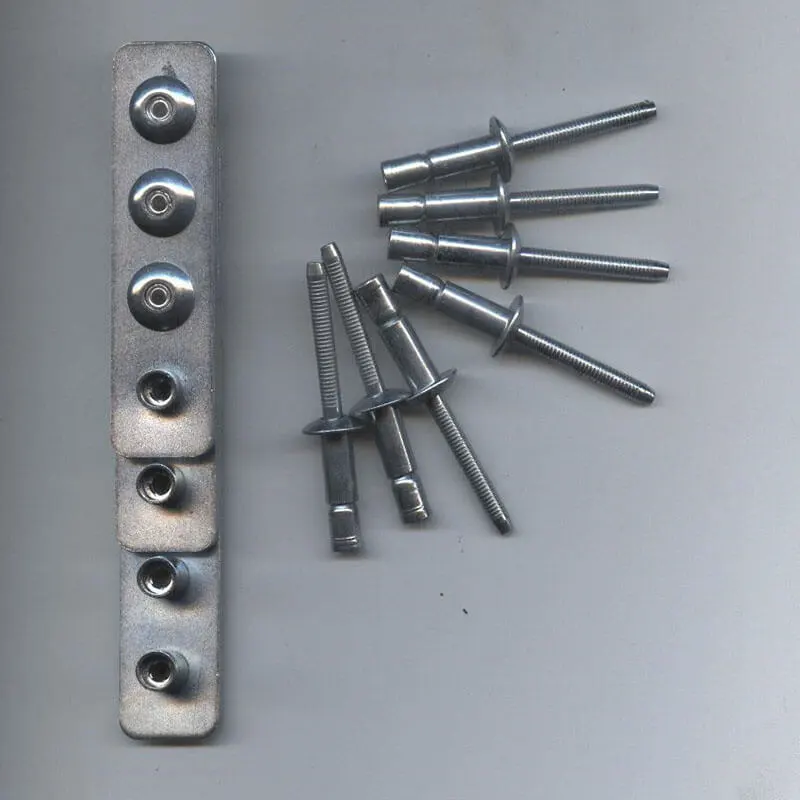

Before starting a new project, you should learn about structural rivets and blind rivets. understand the differences between structural rivets and blind rivets and provide unique value to your customers.

Table of Contents

In the industrial field, a variety of products and projects use structural rivets or blind rivets to provide a safe and stable connection.Structural rivets can provide high strength to condense, which can make your heavy-duty projects safer.Blind rivets can help you with many general projects. You can use them to join a variety of materials, including metal and wood.

In this blog post, we will demonstrate the difference between structrural rivets and blind rivets. You will also learn about their advantages and disadvantages. So, let’s get started.

What are Structural Rivets?

Structural rivets are blind rivets designed for heavy equipment and applications. In everyday use, structural rivets are often found in critical areas. It makes joining and assembling heavy equipment a quick and easy process.

Structural rivets provide ultra-high shear and pullout strengths. In addition, they can be joined with consistent quality. You can use structural rives to create reassuring connections in thin sheets on any heavy-duty project.Structural rivets can also provide your project with special properties such as waterproofing and dustproofing by adding gaskets.

Prons and Cons of Structural Rivets

Now let’s look at the pros and cons of structural rivets.

Prons of Structural Rivets

Structural rivets are a very effective riveted fastener with a variety of advantages. Here are some of the advantages of structural rivets:

- Structural rivets can withstand extremely high shear and pulling forces and are stronger than ordinary rivets. The raw materials used in the manufacture of structural rivets are generally higher strength materials.This characteristic makes them suitable for connections under high loads and dynamic conditions, facilitating their use in automobiles, aircraft and construction.

- Structural rivets have a unique locking design. During the riveting process, its mandrel is securely locked into the rivet body and will not loosen or fall out. This is critical for high vibration environments. This locking mechanism increases the overall strength of the rivet and prevents vibration induced loosening, ensuring long term stability.

- During installation, structural blind rivets provide consistent tightening force and locking depth. This consistency ensures uniform strength at each joint, minimizing installation errors and improving overall structural safety and reliability.

- Structural rivets have a locked mandrel. Structural blind rivets excel in vibration environments, resisting fatigue and loosening caused by vibration. Structural rivets have become indispensable fasteners in the railroad, aerospace and heavy machinery sectors.

- Unlike blind rivets, many structural rivets are designed to be sealed, preventing the ingress of water, air or other substances through the joint. It minimizes the effects of water, gas and dust and is ideally suited to handle automotive bodywork and marine fabrication.

Cons of Structural Rivets

Structural rivets have a number of disadvantages in addition to a variety of advantages. The following are some of the disadvantages of structural rivets:

- Structural rivets are typically made from high strength and corrosion resistant materials such as stainless steel or high strength alloys at a higher cost. While these materials offer superior performance, they also increase the overall cost of the rivet, especially when used in large quantities.

- Structural rivets are typically heavier than regular rivets due to the use of high strength materials. This can become an issue in applications where weight reduction is required, such as aerospace or automotive manufacturing, where a balance between strength and weight is required.

- Structural rivets are primarily used in applications where high strength and reliability are required, and may be too expensive or complex in light duty or general applications. In these cases, the use of structural rivets may not be cost effective and standard rivets or other fasteners may be a better choice.

What are Blind Rivets?

Blind Rivets are the best joining solution for general applications. Blind core rivets do not provide as much strength as structural rivets. Typically, the strength of a blind rivet is half or even one-third that of a structural rivet. You can choose the rivets according to the requirements of the project or the needs of the customer. However, blind rivets can still provide a stable and reliable connection.

Prons and Cons of Blind Rivets

Although we have learned what a blind rivet is, it is still necessary to recognize its advantages and disadvantages.

Prons of Blind Rivets

Blind rivets are an excellent joining solution. Allowing you to complete many general projects, here are some of the benefits of the blind rivet:

- Blind rivets allow you to install from one side very quickly. The biggest advantage of blind rivets is that they can be installed from one side without having to touch the other side of the joint. This feature makes it particularly suitable for enclosed structures, pipes or hard-to-reach areas.

- The installation process for blind rivets is very simple. It can be accomplished using a rivet gun. This makes blind rivets ideal for mass production and rapid installation. It can increase productivity and reducing installation time and labor costs.

- Blind rivets can be used to join a wide range of materials, including metals, plastics, composites and more.

- Blind rivets are typically made of aluminum, stainless steel or other lightweight materials. These materials provide sufficient strength while remaining lightweight. The lightweight nature of blind rivets is especially important in aerospace, automotive manufacturing, and other applications that require weight reduction.

- Blind rivets are designed to prevent the connection from loosening during use and perform particularly well in vibrating environments.

Cons of Blind Rivets

- Compared to structural rivets or bolts, blind rivets have lower shear and pullout resistance. Blind rivets are not suitable for extremely high load applications. Where large mechanical stresses are required, blind rivets may not provide sufficient strength and are prone to failure.

- The head of the blind rivet is often exposed and may detract from the appearance or design requirements of the product. In applications where smooth surfaces or hidden connections are required, blind rivets may not be suitable. The designers need to consider the impact of this exposed portion.

- Blind rivets require a matching hole size. If the hole size is too large or too small, the rivet may not fit correctly or provide adequate tightening force. Drilling accuracy is required during the manufacturing process and any errors may affect the quality of the final connection.

- Although blind rivets are suitable for a wide range of materials, they are not suitable for all materials. For example, in very hard materials, stronger fasteners such as structural rivets may be required.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Structural Rivet vs Blind Rivet: What is the Difference?

Structural rivets are a type of blind rivet. They have many similarities, but they also have significant differences. Here are the main differences between structural rivets and blind rivets.

| Structural Rivet | Blind Rivet | |

| Design Purpose | Designed for high-strength applications, they are capable of withstanding extremely high shear and pull-out forces. | Suitable for general load applications, providing basic stationary functionality. |

| Applications | Used for critical structural connections such as aerospace, automotive chassis, and architectural steelwork. | Used for general industrial and everyday applications such as electronic equipment, home appliances, furniture, etc. |

| Vibration Resistance | Extremely vibration resistant, suitable for long term stable connections in high vibration environments. | Weak vibration resistance and may come loose in high vibration environments. |

| Cost | Relatively high for application scenarios with high performance requirements. | Lower for high-volume, cost-sensitive projects. |

1. Desigh Purpose

Blind rivets were originally invented to solve the problem of not being able to touch both sides of a material at the same time. It is suitable for general load applications and can provide a basic holding function. For connections subjected to high loads, blind rivets are not suitable.

Structural rivets are designed to solve the problem of ordinary blind rivets not being able to withstand high loads. Structural rivets are designed for high-strength applications and can withstand extremely high shear and pull-out forces. Structural rivets are used to complete the joining process, such as steel connections in construction and assembly of critical parts of automobiles.

2.Vibration Resistance

Like in airplanes, automobiles, you’ll find that structural rivets are used a lot more than blind rivets. This is because structural rivets are much more vibration resistant. It can establish a long-term stable connection without loosening under high vibration environment.

3.Cost

Structural rivets have higher strength and better vibration resistance than blind rivets. However, structural rivets are more expensive. This means that you need to pay more financial cost.

Factors to Consider When Choosing Rivets

A variety of factors influence the rivet selection for each project. Here are some of the factors that go into choosing the right type of rivet:

- The application scenario of the rivet will affect the rivet selection. Different application scenarios use different rivets. Structural rivets are not suitable for all scenarios. Therefore, you should consider the load requirements of the application and select the corresponding rivet type.

- Of course, the budget of the project will also affect your choice. If your budget is not sufficient, you need to choose the most cost-effective rivets under the premise of meeting the needs of the application.

Would you like to learn how to choose the right rivets for your project? Please read the hyperlinked article

Which One Should I Choose?

Rivet selection depends on your project requirements. Determine the rivet material you want and the rivet size that corresponds to the hole diameter. Rivets allow you to quickly join materials or components. You can use them in fully automated industrial production plants.

Structural rivets can make your project more secure. Higher strength makes them available for a wider range of applications, including automotive production and repair. It can also help provide your project with special features such as waterproofing.

Therefore, if your project has a high level of strength, structural rivets are for you. However, if it is just to hold the sheets together, you should choose the blind rivets.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Conclusion

Structural rivets and blind rivets are very effective connecting fasteners. It allows you to finish your project quickly. These riveting fasteners also provide a reliable support for your business.

However, you need to make sure that you are using the right rivets for your project. Consider the actual needs of your project to choose the best rivets for your specific requirements. Use pop rivet manufacturer‘s structural rivets to create a perfect project through unique value.

Buy the Right Rivets for Your Project from Rivmate!

Blind rivets and structural rivets are both effective fasteners for joining thin sheet materials.Rivmate offers high quality blind rivets and structural rivets to meet your needs. You can explore several other thin sheet solutions at Rivmate. Request a quote to get the best riveting solution for your project.