Table of Contents

Today, rivets are one of the most commonly used fasteners in industry. So do you know what the purpose of a rivet is? This blog will tell you the history of rivets.

Rivet has always played an irreplaceable role in the field of structural connections. From the age of steam to the present day, rivets have been used as a “permanent connection” solution for structures with high strength and safety requirements, from bridges and ships to aerospace. Compared to screws or welds, riveted connections are not only maintenance-free, vibration-resistant and less prone to loosening, but also offer unique structural advantages by providing a stable and reliable clamping force in situations where it is not possible to work from the back.

In this paper, we will focus on the topic of “What is the purpose of a rivet” to systematically explain the mechanism of action, typical applications and why it is still the first choice for many critical assembly scenarios. An engineering review of its historical evolution and modern technological value helps readers fully understand the centrality of this classic fastener in today’s manufacturing industry.

Table of Contents

What are Rivets?

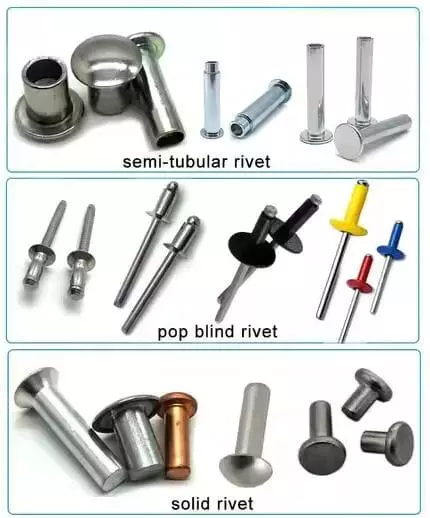

Whether solid rivets, hollow rivets or blind rivets, they are a type of mechanical fastener. Their primary function is to permanently fasten two or more parts (usually metal, plastic or wood) together. A rivet consists of a smooth cylindrical stem and a larger head. During installation, the rod (tail) is deformed or expanded by pressure to create two heads, which are tightened.

Rivet is a reliable mechanical connection. With their wide applicability and excellent performance, rivets play an important role in modern manufacturing and engineering.

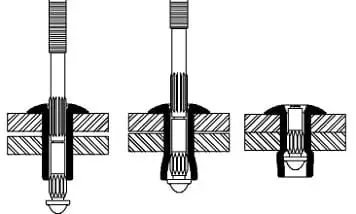

When using rivets, it is necessary to insert the stem of the rivet into a pre-drilled hole in the connecting material in advance. A riveting tool is then used to apply pressure to the stem of the rivet, causing the tail to deform plastically to form a new “head”.

What is the Purpose of a Rivet?

A rivet is a fastener that provides a permanent connection. Its primary purpose is to securely join two or more components together in a mechanically permanent method. Unlike screws, bolts, and other fasteners, rivet connections usually cannot be disassembled after installation, making them suitable for application scenarios that require long-term fixing and vibration resistance. Of course, manufacturers use rivets for more than just permanently securing two or more pieces of material together. Here are some of the main purposes for which users use rivets:

- Fixing components: The basic function of a rivet is to hold two or more materials (e.g. sheet metal, plastic, wood, etc.) together, ensuring that they do not move again.

- Prevents loosening: Rivets are virtually impervious to loosening or falling out due to vibration, friction or external forces.

- Provides a Seal: Blind or sealed rivets provide a good seal at the point of attachment.

- Simplify the installation process: Rivets are often very simple to install and do not require complicated tools or extensive handling.

- Increased Joint Strength: Solid rivets provide more strength than many other fasteners.

- Reduced Damage to Materials: Rivets are installed without excessive heat affected zone (HAZ) on the joining material, thus reducing the risk of deformation or degradation of the material.

- Adaptation to the connection of different materials: Rivets are suitable for the connection of many different materials, especially metals, plastics, composites and so on.

The purpose of rivets is not just to connect, but to provide a long-term, reliable and robust connection. In application scenarios where vibration, corrosion and sealing resistance is required, rivets can still stabilize their simple, cost-effective and efficient installation, and are an important fixing method in a variety of fields such as industrial, construction, aerospace and automotive.

History of Rivets

The history of rivets can be traced back to ancient times, and their application and development has been through many centuries. As a kind of fixed connectors, rivets have played an important role in the process of human manufacturing and construction.

1. Ancient Period

The earliest rivets date back to the 3rd century B.C. in Ancient Egypt and Ancient Greece. During those times, rivets were used to join wood and metal together. Rivets would be used frequently in the construction of ships and in building structures. Ancient rivets were usually hand-forged and made of black iron or copper. They were very simple in function and construction and were mainly used to hold two or more pieces of material together.

2. Medieval and Renaissance Period

As the use of rivets gradually expanded into the Middle Ages and Renaissance, rivets became an important part of architecture and mechanical devices. In construction, rivets were used in the building of large structures such as cathedrals and castles to join steel and wood components. In the maritime industry, rivets were used to build strong wooden hulls to support the structure of ships.

At this time, rivets were mostly solid metal nails that were heated and forged through a process that created a strong connection.

3. Industrial Revolution (late 18th to early 19th century)

The Industrial Revolution gave a great impetus to the development of rivets. With the innovation of steam engines, railroads, and steel manufacturing technology, the application of rivets entered a new stage.

- The wide application of steel: In the early 19th century, with the improvement of steel production technology, steel began to become the main material for rivet manufacturing. The strength and durability of rivets increased dramatically.

- Railroad construction: The construction of railroads requires a large number of rivets to connect rails, bridges and other components. In bridge construction, the use of rivets is critical as they provide a high strength connection that ensures the safety of the structure.

- Shipbuilding: The rise of steel ships has made rivets a standard tool in the construction of ships, especially large iron-hulled vessels.

4. Early Twentieth Century - Modern

Into the 20th century, with the process of industrialization and mechanization, the application of rivets gradually expanded to more fields. In the aerospace, automotive manufacturing and construction industries, rivets became an indispensable connecting tool.

- The emergence of aluminum alloy rivets: with the application of lightweight materials (such as aluminum alloys), rivet materials have also changed. Aluminum alloy rivets are widely used in the aerospace industry due to their light weight and corrosion resistance. The use of aluminum alloy rivets not only improves the efficiency of the connection but also reduces the overall weight.

- Invention of blind rivets: In the early 20th century, blind rivets (pop rivets) came into existence. This type of rivet can be operated unilaterally, making it possible to perform riveting operations in places where space is limited. Blind rivets have been widely used especially in construction, automobile manufacturing and various electronic devices.

- Automated riveting technology: with the automation of manufacturing, rivet installation is also gradually to automation and mechanization direction. Modern rivet guns and automated riveting systems make the riveting process more efficient and accurate.

Do You Have Any Questions?

Let Us Solve Your Problem

Main Applications of Rivets

The main applications of rivets cover a wide range of industries. Below are the main application areas and specific uses of rivets:

- Aerospace: connection of aircraft fuselage, wings and internal support structures. For example, solid rivets are widely used in the fuselage of Boeing and Airbus airplanes.

- Automotive manufacturing: body panels, frames, chassis and interior components. The body structure of electric vehicles is basically connected with rivets.

- Buildings and bridges: metal frames, curtain walls, roof structures and decorative panels are fixed.

- Shipbuilding and offshore engineering: ship hull structures, rig mounting. Rivets are used to fix thin plates where hull welding is inaccessible.

- Furniture manufacturing: joining of wood and metal frames.

Do You Have Any Questions?

Let Us Solve Your Problem

Types of Rivets Materials

| Material Type | Features | Applications |

| Aluminum Rivets | Lightweight, corrosion-resistant, easy to process | Aerospace, automotive, home appliances |

| Stainless Steel Rivets | High strength, corrosion-resistant, high temperature tolerance | Aerospace, marine environments, food processing, chemical industry |

| Copper Rivets | Excellent electrical conductivity, good corrosion resistance, easy to process | Electrical equipment, electronic products |

| Titanium Rivets | Ultra-high strength, extreme corrosion resistance, lightweight | Aerospace, high-end racing, industrial equipment |

| Zinc Alloy Rivets | Economical, moderate strength, good corrosion resistance | Automotive, home appliances, general industrial equipment |

| Carbon Steel Rivets | High strength, low cost, poor corrosion resistance | Industrial machinery, construction projects |

| Galvanized Rivets | Good corrosion resistance, moderate strength, low cost | Automotive, exterior metal components, construction projects |

| Brass Rivets | Good electrical conductivity, corrosion-resistant, moderate strength | Electrical equipment, decorative applications, electronic products |

Future Trends of Rivets

With the manufacturing industry towards lightweight, intelligent and sustainable, rivet technology is ushering in a multi-dimensional innovation and upgrading. The future development trend is mainly reflected in the following directions:

First, high-strength composite material rivets are gradually replacing the traditional metal rivets. In the field of aerospace, rail transportation and new energy vehicles, these companies are using high strength rivets. Through the introduction of titanium alloy, carbon fiber composite core rod and multi-layer structure design, improve the connection strength while significantly reducing the overall weight.

Secondly, the integration of rivets and automated assembly systems has become a mainstream trend. Automatic nail feeding, fast positioning and intelligent inspection technology is accelerating the application of precision manufacturing and high-volume production lines. This solution solves the problem of low efficiency and human error in traditional riveting.

In terms of sustainability, green materials and RoHS compliance requirements have become the new standard. The promotion of lead-free coatings, recyclable aluminum and low-pollution anodizing technologies have made rivets more compliant with global environmental regulations and customers’ ESG policies.

It is worth mentioning that leading rivet brands such as Rivmate are actively exploring structural optimization and new processes to promote riveting technology to achieve leapfrog upgrades in high-end manufacturing.

FAQs

Why use rivets instead of bolts?

A: Rivets are a permanent connection that is not removable after installation and are used in applications where loosening or structural vibration is not allowed. Compared to bolts, rivets are lighter, better suited for high volume assemblies, and still allow for efficient installation in structures where the backside is not accessible.

Do rivets hold better than screws?

A: The structural stability of rivets is superior to that of screws in environments where dynamic loads, vibration, or regular maintenance is not possible. In high vibration industries such as aerospace and automotive, rivets are better able to maintain a durable and reliable connection to avoid loosening or shifting.

What is the use of rivets in the photovoltaic/aerospace/automotive industry?

A: In the photovoltaic system, rivets are used to fix the aluminum profile bracket and panel components. In the field of aviation, rivets undertake high-strength, high-fatigue life connection tasks, is the standard connecting parts of the fuselage skin. In automotive manufacturing, rivets are used for lightweight connection and vibration-resistant assembly of doors, chassis, brackets and other components.

Wholesale Rivets from Rivmate

Rivmate is the top rivet manufacturer in China. Whether it is solid rivets, hollow rivets, blind rivets or structural rivets, you can get satisfactory solutions from Rivmate.

If you are purchasing rivets for your project or business, please contact our engineers. Get a quote today.