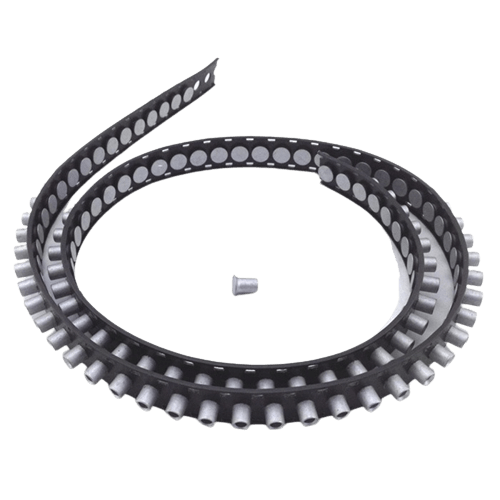

What Material Is Self-Piercing Rivets?

Table of Contents

What material is self-piercing rivets? The selection of materials not only affects the strength of the rivets themselves, but also directly influences their anti-corrosion performance, fatigue life and the reliability of the overall assembly.

The material of self-piercing rivets is the core factor determining the success or failure of the process. Different materials determine whether they can adapt to high-demand applications such as automotive lightweighting, aerospace, or building curtain walls. This blog will systematically introduce the common materials of SPR and provide a professional selection guide.

The material selection of self-piercing rivets (SPR) directly determines their strength, corrosion resistance and service life. Different materials are suitable for different working conditions. Reasonable selection can reduce the risk of failure and extend the service life of the structure. The following are several common types of SPR materials:

a. Carbon Steel SPRs

- Features: High strength and excellent cost performance.

- Applications: Commonly used in the connection of automotive steel plates and in construction steel structures.

- Disadvantages: Insufficient corrosion resistance. Usually requires galvanization, electrophoresis or surface coating treatment to enhance protective capabilities.

b. Stainless Steel SPRs

- Features: It boasts excellent corrosion resistance and high strength. Even in damp, salt spray or chemical environments, it can maintain stable performance.

- Applications: It is used in aerospace, shipbuilding, marine engineering, and various outdoor structures exposed for long periods.

- Disadvantages: It is costly, difficult to process, and requires higher standards for molds and equipment.

c. Aluminum SPRs

- Features: Lightweight and avoids the common problem of electrochemical corrosion in aluminum structures (especially in aluminum-to-aluminum connections).

- Applications: Widely used in automotive lightweight bodywork, home appliances, and electronic product casings.

- Disadvantages: Lower strength than steel and stainless steel, not suitable for components that need to bear high loads or long-term high stress.

d. Special Alloys (e.g., Monel, Titanium)

- Features: It can maintain stable performance under high-temperature, high-corrosion or extreme working conditions.

- Applications: Mainly used in high-end manufacturing fields such as aerospace, energy equipment, and military industry.

- Disadvantages: The cost is extremely high and it is usually only applied in special scenarios.

Comparison Table by Material

| Material | Strength | Corrosion Resistance | Weight | Cost | Typical Applications |

|---|---|---|---|---|---|

| Carbon Steel | High | Medium (requires coating) | Heavy | Low | Automotive steel structures, Building panels |

| Stainless Steel | High | High | Heavy | High | Aerospace, Marine, Outdoor structures |

| Aluminum | Medium | Medium (surface treatment needed) | Light | Medium | Automotive lightweight design, Appliances, Electronics |

| Monel / Titanium | Very High | Very High | Medium | Very High | Aerospace, Energy, Defense |

- Carbon steel SPR

The advantages are high strength and low cost, making it suitable for mass production. The disadvantage is that it has insufficient corrosion resistance and requires galvanization or protective coatings. It is commonly used in automotive body steel plates and building steel structures. - Stainless Steel SPR

It combines strength and corrosion resistance, and can maintain stability in harsh environments. The drawback is that it has a high cost and is difficult to process. Typical applications include aerospace, marine engineering, and long-term outdoor structures. - Aluminum SPR

The greatest advantage is its light weight, which makes it highly suitable for lightweight design. It can avoid electrochemical corrosion of the aluminum-aluminum structure. However, its strength is lower than that of steel and stainless steel, and it is not suitable for high-load components. It is mostly used in aluminum car bodies, household appliances and electronic devices. - Monel / Titanium Alloy SPR

It belongs to high-end application materials and possesses extremely high strength and corrosion resistance. It can be used for a long time in high-temperature, high-salt spray and extreme environments. However, the cost is extremely high and it is only suitable for special fields such as aerospace, energy and military industry.

How to Select the Right SPR Material?

Selecting the appropriate self-tapping rivet (SPR) material requires comprehensive consideration from three aspects: material matching, operating environment, and cost-performance balance. Correct selection can prevent early failure, extend product lifespan, and ensure assembly efficiency.

1) Matching of Materials

Aluminum + Aluminum → Use Aluminum SPR, avoiding electrochemical corrosion and maintaining lightweight characteristics.

Aluminum + Steel → It is recommended to use Steel SPR, but additional surface anti-corrosion measures are required, such as galvanizing or protective coatings.

Steel + Steel → Depending on the requirements, choose Carbon Steel SPR or Stainless Steel SPR. If exposed to a humid environment for a long time, stainless steel is more recommended.

2) According to Environmental Conditions

Indoor Applications → Carbon steel SPR is usually sufficient and offers good value for money.

Outdoor or high humidity environments → Choose Stainless Steel SPR, to ensure long-term corrosion resistance.

Oceans or extreme environments → It is recommended to use Monel or titanium SPR, which can maintain stable performance even in high salt spray and strong corrosive conditions.

3) Based on the Cost vs Performance Tradeoff

Carbon Steel SPR: The lowest cost, suitable for large-scale standard applications.

Aluminum SPR: Balances lightweighting and moderate corrosion resistance requirements, commonly used in automotive lightweighting designs.

Stainless Steel SPR: It has a relatively high cost, but it is indispensable in aerospace, marine and outdoor engineering applications.

Monel / Titanium SPR: This belongs to the high-end solution category. Although it is extremely costly, it holds unique value in the fields of aerospace, energy, and military industry.

Surface Treatments for SPRs

In the application of self-tapping screws (SPR), surface treatment plays a crucial role in corrosion resistance, service life and reliability. Different surface treatment methods have their own advantages and are suitable for different scenarios.

Galvanized (Zinc-Plated) SPRs

Galvanization is the most common SPR (Steel-Prepared-Rust-Free) anti-corrosion treatment method. It covers the surface of the rivets with a layer of zinc to form a barrier, preventing the steel from directly contacting air and moisture, thereby delaying corrosion. The galvanization process is mature and has a low cost, so it is widely used in automotive steel structures and interior assembly. It should be noted that in high salt spray or marine environments, a simple galvanized layer may be insufficient, and usually additional protective measures need to be combined.

Nickel or Tin Plated SPRs

Nickel-plated or tin-plated SPR is more durable than galvanized coating and can significantly enhance corrosion resistance and wear resistance. These treatment methods are highly suitable for scenarios requiring long-term stable operation, such as aviation components or the electronics industry. The nickel plating layer also has certain electrical conductivity and is suitable for assembly in electrical equipment. However, the process cost of nickel plating or tin plating is higher, so it is usually only applied to products with extremely high requirements for durability and reliability.

Anticorrosive Coating (E-coating, Organic Coating)

Electrophoretic coating (E-coating) or organic anti-corrosion coating can form a uniform and dense protective layer on the SPR surface. This coating not only effectively resists salt fog, acidic environments and chemical corrosion, but also can form a covering in the gaps of complex structures, providing a better protective effect than traditional coatings. Therefore, this type of surface treatment is often used in marine engineering, building facades and equipment exposed to the outdoors for a long time. Compared with galvanizing or nickel plating, although the anti-corrosion coating is slightly more expensive, it can significantly extend the service life of SPR in harsh environments.

Applications by Material

1. Automotive Industry

Carbon steel SPR: Commonly used in vehicle body steel structures, it can provide high-strength connections and is suitable for withstanding impacts and vibrations.

Aluminum SPR: Widely used in aluminum alloy vehicle bodies, it helps automobiles achieve lightweight design, reducing fuel consumption and carbon emissions.

2. Aerospace

Stainless Steel SPR: Used in aircraft fuselage connections and cabin door components, it offers high strength and corrosion resistance.

Titanium SPR: Suitable for use in high-temperature and highly corrosive environments, commonly found in the vicinity of engines and critical structural parts.

3. Construction Industry

Carbon steel SPR + surface galvanization: Suitable for curtain walls, steel structure frames and roof systems. The galvanization process enhances corrosion resistance and prolongs the lifespan of the building.

4. The Appliance Industry

Aluminum SPR: Suitable for the shells of refrigerators, washing machines, air conditioners, etc. Aluminum material is not only lightweight but also maintains a good appearance, and is suitable for rapid assembly of thin plate structures.

Rivmate Expertise & Solutions

As a professional supplier of self-piercing riveting (SPR) solutions, Rivmate continuously innovates in material research and surface treatment to ensure that its products can meet the strength, corrosion resistance and durability requirements for various application scenarios.

① Material of Rivmate SPR Products

- Boron steel (37MnB5 / 36MnB4) Rivmate widely adopts this type of high-strength boron steel in the foreign trade market, replacing the earlier used SCM435. Its performance is stable and it is suitable for most automotive and construction applications.

- 304 Stainless Steel Due to insufficient hardness, it is currently impossible to effectively penetrate the 5-series aluminum plate, so production has not yet been carried out.

- 420 Stainless Steel (Iron-based, Carbon-containing) The hardness can be enhanced through heat treatment, and it is capable of piercing 5-series aluminum materials. However, there are still limitations when it is applied to 6-series and 7-series aluminum materials.

② Rivmate SPR Surface Treatment

- Mechanical Galvanizing (Zinc-Tin Alloy) → Can achieve 240H without rust, suitable for medium-level corrosion prevention needs.

- Zinc-Nickel Electroplating (Zinc-Nickel Alloy) → Provides 480H without rust, with superior corrosion resistance.

- Dacromet (Zinc-Aluminum Coating, Chromium Included) → Common protective method, can reach 240H without rust.

- ALMAC (Zinc-Aluminum Coating, Chromium-Free, Environmentally Friendly) → Offers 480H without rust, compliant with environmental regulations.

③ Support Provided by Rivmate

- Engineering Material Selection Recommendation: Based on the customer’s material combination and process requirements, we recommend the most suitable SPR material and surface treatment.

- Material Compatibility Consultation: Assist customers in avoiding electrochemical corrosion issues between different materials such as aluminum and steel.

- Customized Solutions: According to the specific industry requirements, we provide exclusive material optimization and coating customization services.

FAQ

Q1: What is the most common material used in SPR?

Answer: Currently, the most common type is carbon steel SPR. It has high strength and low cost, making it suitable for large-scale applications such as in automobiles and construction. If corrosion resistance is required, it can be combined with galvanization, nickel plating or coating processes.

Q2: Can steel SPR be used on aluminum materials?

Answer: Yes, but be aware of the issue of corrosion prevention. The combination of steel and aluminum may result in electrochemical corrosion. It is recommended to perform appropriate surface treatments (such as galvanizing, ALMAC) or add an isolation layer to ensure long-term reliability.

Q3: What material is the most suitable for SPR in marine environments?

Answer: In marine environments, Stainless Steel SPR or Monel/Titanium SPR perform the best. They can resist salt fog and long-term humid conditions. However, cost considerations should be taken into account. Titanium and Monel are typically used for high-end or critical components.

Q4: Can Rivmate offer customized SPR materials?

Answer: Yes. Rivmate can provide customized material options (such as special alloys) and surface treatment solutions (such as the 480H corrosion-resistant ALMAC coating) based on the customer’s working conditions. We can also offer material compatibility consultation to prevent connection failure due to improper material selection.

The materials of self-tapping screws (SPR) mainly include carbon steel, stainless steel, aluminum and special alloys. Each material has its own advantages: carbon steel focuses on cost-effectiveness, stainless steel emphasizes anti-corrosion performance, aluminum meets the demand for lightweight, and special alloys are suitable for extreme environments. The correct selection of material is the key to ensuring connection strength, durability and cost control.

Contact us to obtain customized material and surface treatment solutions, enabling your project to achieve the optimal balance between performance and cost.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met