History of Rivets

Table of Contents

When exploring the history of metal connection methods, History of Rivets is always an unavoidable topic. As one of the oldest mechanical fasteners, rivets have a history of application for thousands of years. From the bronze artifacts of ancient Egypt to the bridges and armor of the Roman Empire, rivets have always been one of the most reliable structural connection methods in human civilization. The question is, why can rivets survive for thousands of years and still be active in the core areas of modern industry?

From the ancient manual craftsmanship to the large-scale application during the Industrial Revolution, and then to the widespread use of blind rivets and self-tapping rivets in modern aviation, architecture, and automotive industries, we will systematically analyze the evolution process of rivets. From this perspective, you will understand how rivets have maintained their unique position in technological changes and remain the preferred connection method for engineers and manufacturers.

Origins of Rivets

The history of rivets can be traced back to around 3,000 BC, which was the earliest period when humans knew to use metal fasteners. Archaeologists discovered early rivets on ancient Egyptian bronze artifacts, ornaments and tools. These rivets were mostly small metal pegs, used to fix the edges of bronze sheets to prevent cracking or loosening of the objects over time. This practice demonstrated the early understanding of humans regarding mechanical connection and structural stability.

During the Ancient Greek and Roman periods, the application scope of rivets expanded significantly. With the widespread adoption of iron smelting technology, iron rivets gradually became the mainstream and were widely used in bridges, chariots, ships, armor and helmets. In the large stone bridges and aqueducts built by the Romans, iron rivets and metal connectors worked together to ensure the stability of these magnificent structures over hundreds of years. In military equipment, rivets not only provided a strong protective effect but also gave the soldiers’ armor some flexibility.

The production method of these early rivets was mainly through hand forging, and their structure was relatively simple, usually only serving the functions of fixation and compression. Nevertheless, their value cannot be underestimated: on the one hand, it proved the feasibility of cold processing metal connection technology; on the other hand, it also laid the foundation for the subsequent development of diversified rivet structures (such as solid rivets, blind rivets, self-tapping rivets). It can be said that rivets are an important witness of the transition from ancient metal processing to modern industrial connection.

Rivets in the Industrial Revolution

From the 18th to the 19th century, the Industrial Revolution brought about unprecedented technological changes. The emergence of steam engines, railway transportation, steel smelting, and large-scale shipbuilding industries placed greater demands on reliable structural connection methods. Against this backdrop, rivets, due to their advantages of high strength, resistance to impact, and the ability to be mass-produced, gradually became indispensable fasteners in the industrial era.

The Invention and Derivation of Riveting Technology

In the early days, rivets were mostly made by hand, with limited efficiency. As the Industrial Revolution progressed, the Hot Riveting process was invented and widely adopted. Workers would heat the rivets to a red-hot state, insert them into the connection holes, and then have the riveters quickly hammer them into shape. The head of the cooled and contracted rivet would firmly lock the two steel plates together. This process not only enhanced the connection strength but also significantly improved the construction efficiency.

Meanwhile, different structural requirements have led to the emergence of new types of rivets:

- Solid Rivets: Primarily used in high-strength projects such as bridges and shipbuilding.

- Semi-Tubular Rivets: Reduce the hammering force and are suitable for mechanical assembly.

- Large-Diameter Rivets: Satisfy the connection requirements for railway rails and thick plates.

These technological innovations and product developments made rivets one of the most representative engineering technologies in the Industrial Revolution.

During the Industrial Revolution, almost all major infrastructure and transportation systems relied on rivets:

- Railways and Bridges

The widespread use of railways is inseparable from the use of rivets. Whether it’s the tracks, carriages, or bridges spanning rivers, rivets play a crucial role. For instance, the Forth Bridge (completed in 1890) in the UK used 6 million rivets and is still in service today, being hailed as a symbol of Victorian industry. - Eiffel Tower (1889)

This Parisian landmark structure utilized over 2.5 million rivets. The rivets not only provided structural strength but also became an integral part of the “steel aesthetics”, elevating the riveting process from a mere engineering technique to a symbol of industrial art. - The Titanic (1912)

As the most advanced ocean-going vessel at that time, the Titanic was held together by approximately 3 million rivets. Although subsequent investigations revealed that some of the rivets might have had quality issues, this still demonstrated the irreplaceable importance of rivets in large-scale engineering projects at that time. It represented an ultimate attempt in human industrial manufacturing capabilities.

Evolution in Modern Manufacturing

In the 20th century, with the rapid development of welding technology, some traditional riveting methods were gradually replaced. Welding can achieve faster assembly efficiency and higher structural integrity, so it has become the main process in shipbuilding, steel construction and railways. However, welding cannot cover all applications completely, especially in the connection of different materials and single-sided installation scenarios, where rivets still have an irreplaceable advantage.

In this context, new types of riveting techniques have emerged one after another:

- Blind Rivets:

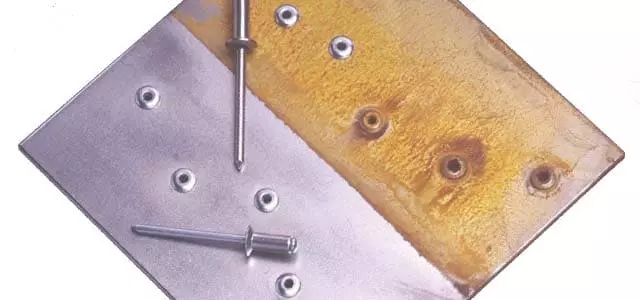

Introduced in the 1930s by George Tucker Eyelet Company. It solved the problem of single-sided operation and greatly simplified the installation process. Blind rivets quickly gained popularity in aerospace maintenance, home appliance assembly, and building facades, and have become one of the most commonly used fasteners. - Self-Piercing Rivets (SPR):

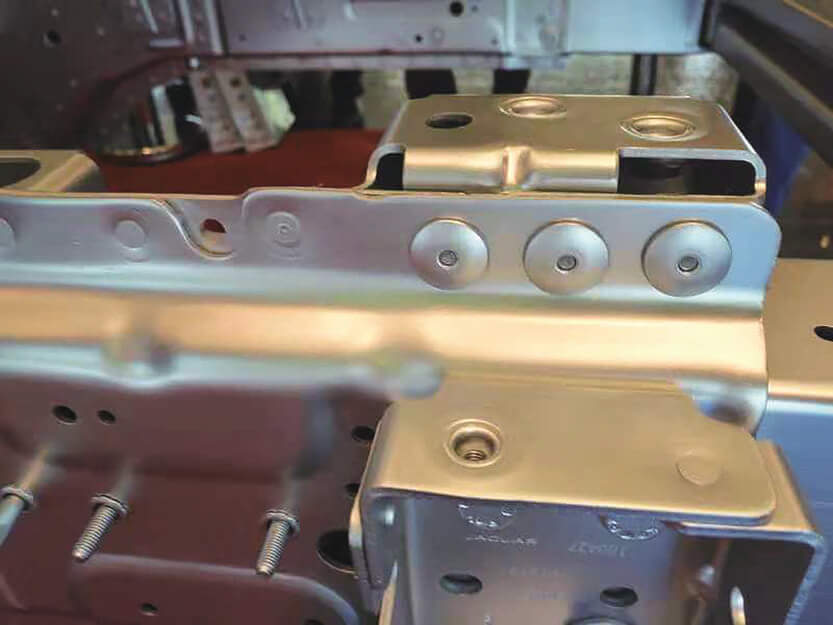

With the increasing demand for automobile lightweighting and aerospace manufacturing, SPR came into being. It can directly penetrate the material and lock in place without the need for pre-drilling, making it particularly suitable for aluminum + steel, aluminum + composite materials joint connections. It is widely used in electric vehicle and aircraft manufacturing.

Iconic Applications by Industry

a. Architecture

During the period from the 19th century to the early 20th century, rivets were the most crucial structural connecting components in the construction of high-rise buildings and bridges. Take the Chrysler Building in New York (completed in 1930) as an example. The entire building used millions of rivets to fix the steel beams, ensuring stability under extreme conditions such as wind loads and earthquakes. Similar classic bridges, such as the Tower Bridge in London (completed in 1894) and the Brooklyn Bridge (completed in 1883), relied almost entirely on rivet connections for their steel structure. These buildings remain stable to this day, demonstrating the long-term reliability of rivets in architectural history.

b. Aviation

In the aviation industry, the role of rivets remains unchallenged to this day. Compared to welding, rivet connections are more suitable for withstanding high-frequency vibrations and alternating loads. A Boeing 747 requires approximately 6 million rivets, most of which are used for fixing the wings and fuselage skins. The number of rivets in the Airbus A380 is even larger. This not only demonstrates the importance of rivets in terms of safety, but also reflects their advantages in aviation maintenance – a single rivet can be replaced independently without having to re-weld the entire structure, significantly reducing maintenance risks and costs.

With the development of the “new energy vehicles and lightweighting trends”, the mixed use of aluminum and high-strength steel is becoming increasingly common. Traditional welding is prone to generating heat-affected zones and corrosion problems when dealing with different metals. Therefore, “Self-Piercing Rivets (SPR)” has become the industry standard. For example, in the aluminum body design of Jaguar Land Rover, each vehicle uses an average of 2,500 – 3,000 SPR. These rivets not only ensure strength but also meet the requirements for efficient automated assembly.

Before the widespread adoption of welding technology, rivets were almost the only means of connection for large ships. The most representative case is the Titanic (1912), whose hull was held together by approximately 3 million rivets. Although some studies suggest that poor-quality rivets in the bow area might have accelerated the sinking process, overall, it still represents one of the most complex and largest riveting projects at that time. Even today, in some ship repair projects and special ships (such as warships and ice-breaking ships), rivets still play a role that welding cannot replace, especially in structural areas that require resistance to fatigue and impact.

Why Rivets Still Matter

Strength and Reliability

In environments with high vibration and high fatigue loads, rivets tend to be more stable than bolts. For instance, in the aviation industry, aircraft experience intense impacts during takeoff and landing. The mechanical locking of rivets can prevent the risk of bolt loosening. Data shows that rivet connections have a fatigue life improvement of 20% – 30% compared to spot welding.

Adaptability

Compared with welding, rivets can easily achieve the connection of different materials. Combinations such as aluminum and steel, or metal and composite materials are becoming increasingly common in the automotive and construction industries. Welding often leads to electrochemical corrosion or thermal influence, while rivets can avoid these problems and ensure structural stability.

Riveting is suitable for the automated integration of large-scale production lines. Both self-piercing Rivets (SPR) and Blind Rivets can be installed quickly, reducing assembly time. Research shows that the assembly efficiency of a single vehicle on a complete vehicle production line using an automated riveting process can be increased by more than 15%. This keeps rivets competitive in modern manufacturing.

Rivmate Expertise & Insights

Rivmate, as a professional fastener supplier, not only excels in traditional solid rivets but also continuously innovates in modern riveting techniques. We offer a complete product line including blind rivets, self-tapping rivets (SPR), and structural rivets, which can meet the assembly requirements of various industries.

In practical applications, the performance of rivets is not only determined by the material, but also closely related to the installation process and structural design. The technical team of Rivmate provides customers with comprehensive support including material selection (aluminum, stainless steel, titanium alloy, Monel), surface treatment solutions, and corrosion prevention optimization, ensuring that the rivets maintain reliable performance in different environments.

Furthermore, Rivmate provides in-depth services to key industries such as construction, automotive, aviation, and shipping. Whether it is the structural safety of bridges and skyscrapers, the lightweight requirements of new energy vehicles, or the high-strength and fatigue resistance demands of aircraft manufacturing, Rivmate can combine historical experience with modern technology to assist customers in making the best selection.

Through the “global supply chain and local service network”, we not only ensure the stability of delivery, but also provide customers with “test verification and process improvement suggestions”. This makes Rivmate a reliable long-term partner for our customers.

FAQ

Q1: Where was the earliest application of rivets in the world?

The earliest known example dates back to around 3000 BC in ancient Egypt. Small metal pegs were used to fix the bronze joints of objects, enhancing their durability. Subsequently, this technique was extended to structures such as bridges, chariots, armor and helmets in ancient Greece and Rome.

Features: Hand-forged, simple in shape, but already demonstrates the rudimentary form of “cold processing mechanical connection”.

Q2: Why were the rivets used on the Titanic criticized for being of poor quality?

The research indicates that the dross content of the “mature iron rivets” used in areas such as the bow of the ship is relatively high, and their toughness is insufficient. In low-temperature seawater, the material’s brittleness increases, and it is more prone to cracking or being pulled out under local impact. At that time, the consistency of process and quality was limited: the quality of rivets from different batches and different ship sections varied greatly.

Core conclusion: Systemic failure (resulting from the combination of design, materials, processes and operating conditions), rather than a single “bolt failure”.

- Appearance Time: Solid rivets were first seen in ancient times; Blind rivets were industrially popularized in the 1930s and were used to solve the problem of single-sided installation.

- Process Path: Solid rivets are pressed tightly on both sides by plastic forming; blind rivets are locked in place by the core rod breaking, without requiring back operation.

- Application Iteration: During the Industrial Revolution, Large Structures = Solid Rivets Dominated; In modern maintenance, household appliances, and thin plate assembly, Blind Rivets Became Popular; The lightweighting of automobiles led to the emergence of SPR.

- Maintenance method: Solid rivets are mostly used in scenarios where both sides are accessible; blind rivets facilitate quick replacement and on-site maintenance.

Q4: Can Rivmate supply rivets that meet aviation/construction standards?

Yes. Products that comply with common standards such as ISO/DIN/IFI can be supplied according to project requirements; for aviation/transport projects, they can be aligned with specifications like NAS/MS/AS (subject to the drawings and terms).

Provide material and heat treatment traceability (such as EN 10204 3.1 material certificate), shear/tensile test reports, and can conduct salt spray (ASTM B117/ISO 9227), dimensional tolerance and assembly verification as per requirements.

Support for sample production and small-scale trial production, surface treatment (zinc-nickel, Dacromet/ chromium-free alternatives, ALMAC, etc.) and process window assessment to ensure compliance and durability requirements for various industries such as aviation, construction, automotive, and shipping.

Build the Future with Rivmate Riveting Solutions

The history of rivets can be traced back thousands of years. From the bronze artifacts of ancient Egypt to the bridges of the Roman Empire, and then to the railways and shipbuilding projects of the Industrial Revolution, it has always been the most reliable connection method in human engineering development. Even with the widespread adoption of welding and advanced fastening technologies today, rivets still hold an irreplaceable position due to their strength, durability and adaptability.

Rivmate combines this historical heritage with modern technology to offer high-strength rivet solutions for industries such as aviation, automotive, construction, and shipping. Whether it’s standardized mass production or customized engineering support, we can assist our clients in achieving greater safety and efficiency.

👉 Contact Rivmate to obtain the historical accumulation + technological innovation fastening solutions and jointly create a reliable structure for the future.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met