Table of Contents

Well nuts vs rivets are a concern for many business owners. Well nuts and rivets are both commonly used fasteners in industry. For many people, correctly stating the difference between them can be a daunting task. However, we want to show you the differences between weld nuts and rivets in this guide.

We will compare all the important features, applications, advantages and disadvantages. Let’s explore together!

Table of Contents

What Are Well Nuts?

Well Nuts consist of a metal nut embedded in a rubber housing. These fasteners are often used for connections on thin sheets, metals, plastics or other materials. It provides a strong connection in environments where vibration, shock, or sealing is required.

What Are Rivets?

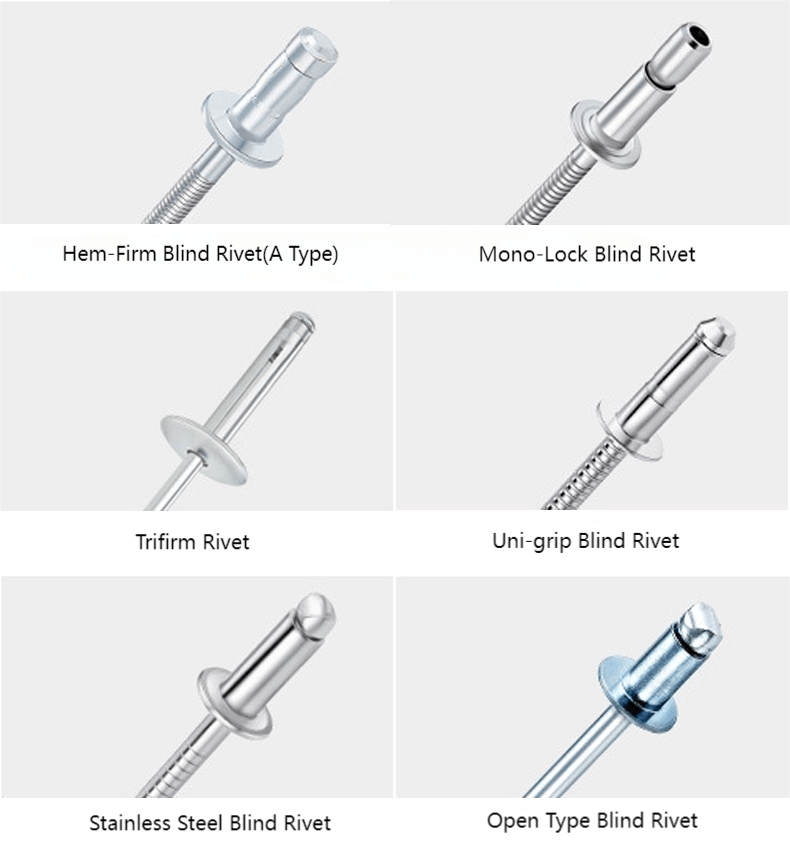

Rivet can hold two or more different or identical materials together. Generally, rivets provide a permanent connection. Once properly installed, they are very difficult to remove unless the structure of the rivet is destroyed.

Rivets offer the advantages of high strength, excellent durability and versatility. These characteristics have led to their widespread use in industrial and engineering applications. Rivets are ideal in applications where long-term stability and high reliability are required.

Well Nuts vs Rivets : Installation Methods

There is a significant difference between Well Nuts and Rivets in terms of installation methods.

The installation of Well nuts does not require complicated tools, only bolts and spanners are needed to complete the installation. Installation of well nuts is simple, but requires precise control of the tightening force to avoid excessive compression of the rubber. This can still be difficult.

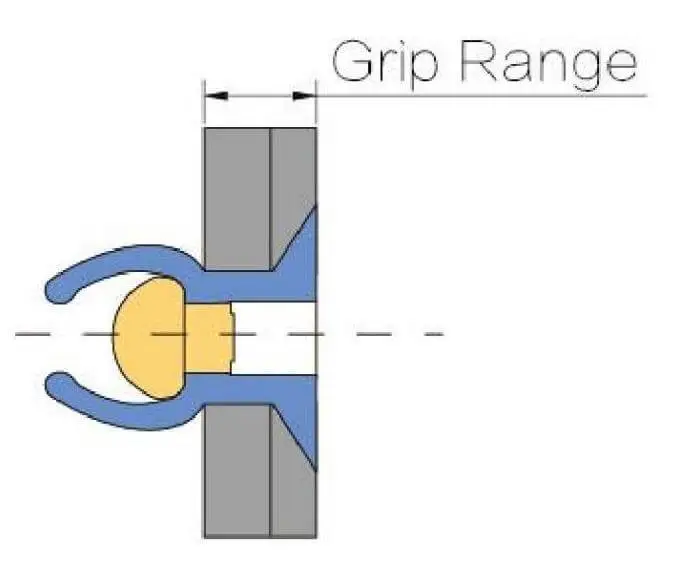

The installation of rivets is simpler and faster. The operator only needs to use a rivet gun to complete the installation of blind rivets.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

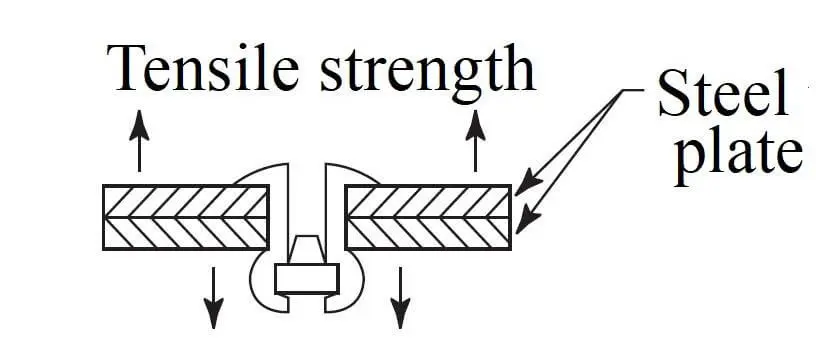

Well Nuts vs Rivets: Strength

Common fastener strengths include the following:

- Tensile strength

- Shear strength

- Stress distribution

- Durability of the connection

In practice, well nuts are more commonly used in low to medium strength applications. While rivets can be used in both low to medium and high strength applications.

Well nuts have a lower pullout strength due to the more limited expansion force provided by the rubberized shell. The shear strength of well nuts is limited by the friction of the rubber.

There are many types of Rivets. Rivets can provide high blind rivet shear strength and blind rivet tensile strength, and since the rivet body expands and extrudes to hold the joint material, the stresses are evenly distributed throughout the joint area.

Well Nuts vs Rivets : Fatigue Performance

Well nuts are made of rubber and nuts. The fatigue properties of rubber can easily and gradually deteriorate under long-term dynamic loading. This leads to a gradual loss of elasticity and strength, ageing, cracking and deformation of the well nuts.

Rivets are usually made of aluminium, steel, stainless steel or other high-strength metals. These materials have excellent fatigue resistance. Metal rivets maintain structural integrity under repeated loads and are less susceptible to fatigue fracture. As a result, Rivets offer greater reliability and durability under dynamic loading.

Differences Between Well Nuts and Rivets in Terms of Applicable Materials

Rivets and well nuts both work well for joining metal materials. The following types are included:

- Aluminum

- Carbon Steel

- Stainless Steel

- Copper

- Brass

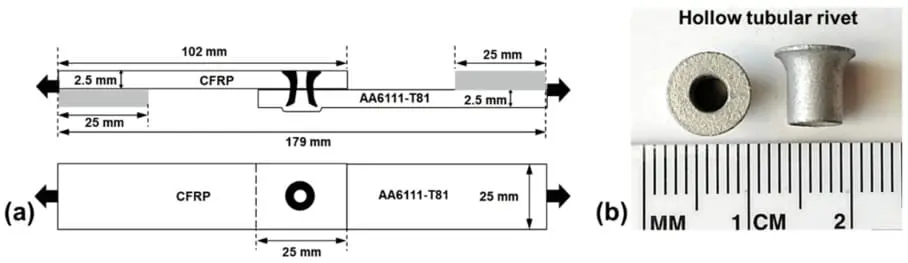

In addition to metal materials, rivets has an even wider range of joining materials. If your project is to join plastic, wood or composite materials, then you should choose rivets for the joining.

Rivets vs Well Nuts: Cost

The cost of a fastener is evaluated in two main ways.

- Cost of materials

- Cost of Installation

Well nuts have a higher unit and installation cost.

The price of Rivets is determined by the raw materials used in manufacturing. The raw material is expensive, the price of rivets will be higher. But the installation of rivets is very fast and cheap. Its installation cost is extremely low. Operators can directly install it without training.

Well Nuts vs Rivets: Thickness of the Connection

Well nuts are suitable for joining thin materials. If your project has a certain thickness, well nuts may not perform as well.

Rivets can be applied to a wide range of material thicknesses. Whether it’s a thin sheet of material or a material with a certain thickness, rivets have a type of rivet that can be matched. For materials of varying thicknesses, rivets of the appropriate length can be selected to accommodate the different thicknesses.

Material Composition of Rivets and Well Nuts

There are also many differences in the materials used to make well nuts and rivets.

| Materials | Types | |

| Well Nuts | Caoutchouc | Neoprene EPDM Caoutchou |

| Metal | Copper Stainless Steel Galvanised Steel | |

| Rivets | Metal | Aluminum Steel Stainless Steel Monel Copper |

Comparison of Well Nuts and Rivets : Removability

Well nuts provide an excellent connection point for thin sheet connections.Well nuts are a removable, reusable connection. The bolts can be installed and removed several times.

Rivets are usually considered permanent connections. Once properly installed, the only way to replace or repair them is through destructive removal. The operator needs to destroy the internal structure of the rivet so that it is rendered completely useless.

Difference in Application Between Rivets and Well Nuts

Well nuts provides excellent shock and water resistance due to the expanded and flexible design of the rubber housing. They are therefore particularly suitable for applications where vibration is to be absorbed, noise is to be minimised and a seal is to be provided. Commonly used well nuts are used in the following applications:

- Housings or components for electronic equipment

- Vehicle interior panels, trim strip fixing

- Outdoor equipment that needs to be sealed or waterproof. Solar devices, weather instruments, etc.

Rivets provide high strength and permanent fixing through mechanical deformation.Rivets are used where long term stability is required and connections cannot be loosened.

Rivets are especially structural due to their unique design. The locking structure is designed to provide long-lasting connection strength even in harsh environments.

Rivets are used in a much wider range of scenarios than well nuts. Whether it is a light application or a heavy application, rivets provide a stable connection. Below are some common application scenarios for rivets.

- Wing, fuselage sheet metal fixingFixing of bridges

- building steel structures

- Assembly of car bodies and chassis

Quick FAQS

There are many types of raw materials used in the manufacture of rivets.Stainless steel rivets will not rust.Carbon steel blind rivets will use some anti-rust measures to prevent the rivets from rusting.

Therefore, if rusting of rivets is a concern for your project, you can choose a rivet material that will not rust. Or use some rust release measures.

Typically, rivets would be considered a permanent connection. Once rivets are properly installed, there is no way to remove them unless the structure of the rivets is damaged.

How to Choose Between Well Nuts or Rivets?

Although well nuts and rivets are used to join thin sheet materials. However, you can choose them correctly by the actual project requirements.

- Choose Rivets: When you need a high-strength, permanent connection, especially in harsh environmen.s, Rivets is the better choice for industrial and structural applications.

- Choose Well Nuts: When you need shockproof, waterproof, removable connections and a more complex environment (e.g., needing to seal or accommodate material deformation).Well Nuts are the more appropriate choice for low- to medium-strength applications such as electronics, automotive and outdoor equipment.

Conclusion

By reading the information in this guide, you now have a clear idea of the difference between well nuts and rivets.

If you are planning to purchase rivets, you can contact our engineers. They will provide you with professional answers and rivets solutions.