Custom Steel Blind Rivets from Rivets Factory

Carbon Steel Blind Rivets are typically used in applications demanding high connection strength and structural reliability, or as critical connecting components within products. Compared to aluminum rivets, carbon steel offers superior tensile and shear strength, maintaining stable connections under heavy loads.

Due to their superior mechanical properties and durability, carbon steel blind rivets are widely adopted across various industrial sectors, including machinery equipment, steel structural components, and industrial assembly. When paired with appropriate surface treatments (such as galvanization), they also offer adequate corrosion resistance, ensuring a long service life even in demanding operating conditions.

Types of Steel Blind Rivets

Due to the inherent high strength and load-bearing capacity of steel, a wide variety of blind rivet types are manufactured from this material to meet diverse structural and operational requirements. Among these, Carbon Steel Blind Rivets represent the most common and widely applied category.

Carbon steel blind rivets are typically employed in critical structural components and heavy-duty equipment, where they are well-suited to withstand significant tensile and shear loads. In industrial practice, they are frequently utilized in machinery, steel structural assemblies, and engineering installations as essential fasteners ensuring overall structural integrity. When paired with appropriate surface treatments, carbon steel blind rivets also maintain excellent durability in demanding environments.

Carbon Steel Open Type Blind Rivets

Carbon Steel Sealed Type Blind Rivets

Carbon Steel Uni-grip Blind Rivets

Carbon Steel Multi-grip Blind Rivets

Carbon Steel Interlock Rivets

Carbon Steel Monobolt Rivets

Carbon Steel Hemlok Rivets

Carbon Steel Lockbolt Rivets

Carbon Steel Bom Rivets

Carbon Steel Hucklok Rivets

Carbon Steel Self Piercing Rivets

Carbon Steel Ground Rivets

Carbon Steel Grooved Type Blind Rives

Carbon Steel Q Rivets

Carbon Steel Speed Rivets(BRV Series)

Carbon Steel Speed Rivets(CBT Series)

Steel Blind Rivets Sizes

Rivmate offers multiple specifications of Steel Blind Rivets for various projects, accommodating different material thicknesses and load requirements. Common diameter specifications include:

3/32″ (2.4 mm), 7/64″ (3.0 mm), 1/8″ (3.2 mm), 5/32″ (4.0 mm), 3/16″ (4.8 mm), 6/32″ (5.0 mm), 15/64″ (6.0 mm), and 1/4″ (6.4 mm). These sizes cover a wide range of applications from light-duty to medium-load structural connections.

In engineering selection, smaller diameters suit thin sheet metal and light-duty assemblies, while larger diameters provide higher tensile and shear resistance for critical structural applications. Should standard specifications fail to meet your project requirements, Rivmate also supports custom manufacturing, including non-standard diameters, lengths, and clamping ranges, to ensure optimal riveting performance and structural integrity.

Types of Steel Blind Rivets Head

Different projects have varying requirements for blind rivet head types. Selecting the appropriate head type helps achieve a balance between strength, appearance, and material protection. For most general assembly applications, Dome Head Steel Blind Rivets offer broad applicability and stable installation, meeting standard structural connection needs.

When applications demand surface flatness, Countersunk Head Steel Blind Rivets are the preferred choice. Their flush-mounted finish facilitates subsequent bonding, sliding, or decorative treatments.

For projects involving fragile or soft materials like sheet metal, plastics, or composites, Large Flange Head Steel Blind Rivets provide a larger load-bearing surface. This reduces the risk of material damage and enhances connection reliability.

Rivmate offers all three head types of steel blind rivets, enabling flexible selection for diverse applications to ensure optimal assembly results and structural integrity.

Rivet & Mandrel Materials

In practical applications, the rivet body and mandrel of blind rivets are not necessarily made of the same material. By combining different materials, an optimal balance can be achieved between strength, corrosion resistance, and cost.

Aluminum Body & Carbon Steel Mandrel

This combination offers lightweight properties and smooth installation, with the mandrel providing sufficient tensile force to form a stable back structure. Suitable for light to medium load applications while meeting moderate corrosion resistance requirements.

Carbon Steel Body & Carbon Steel Mandrel

The all-steel construction delivers higher tensile and shear strength, making it suitable for critical structural areas and heavy-duty applications. Commonly used in machinery, steel structures, and industrial assembly scenarios.

Copper Body & Steel Mandrel

This pairing combines excellent electrical conductivity with installation strength. It is frequently used in electrical-related or specialized industrial applications while maintaining stable riveting performance.

Grip Range of Steel Blind Rivets

Rivet Grip Range is one of the critical parameters in selecting steel blind rivets. The grip range directly determines whether the rivet can form a stable back-side deformation under varying total material thicknesses, thereby affecting installation reliability and final joint strength.

Incorrect selection of the rivet grip range may result in incomplete expansion, loosening, or pull-out issues. Properly matching the grip range ensures effective locking of the rivet across varying material thickness combinations.

In practical applications, Steel Blind Rivets typically cover a broad clamping range. Common parameters include:

- Minimum clamping range: 0.020 – 0.062 inch, suitable for ultra-thin sheets or light-load connections.

- Maximum clamping range: 1.125 – 1.250 inch, meeting assembly requirements for multi-layer panels or thicker structural components.

When selecting for engineering applications, it is recommended to make a comprehensive assessment based on the total thickness of the materials being joined, the rivet diameter, and the load requirements.

Applications of Steel Blind Rivets

Steel Pop Rivets for Car Manufacturing

Carbon Steel Blind Rivets are commonly used in the automotive manufacturing process to attach metal panels of automotive bodies (such as doors, roofs, fenders, etc.) to the frame structure. The high strength of Carbon Steel Blind Rivets makes them suitable for securing these critical exterior and interior structural components in environments subject to vibration and stress.

Steel Pop Rivets for Building Structures

Carbon steel blind rivets are used to connect load-bearing steel beams and other metal framing components in structural steel buildings. Due to their durability and strength, Carbon Steel Blind Rivets provide long-lasting, strong connections in building frames. They are also widely used to secure exterior metal structures such as curtain walls and parapets.

Steel Pop Rivets for Transportation Facilities

The fixing of traffic facilities requires high strength fasteners. Carbon steel blind rivets have high tensile strength and strong vibration resistance for the reason that they are widely used in fixing metal guardrails, road signs and signal light brackets in traffic facilities.

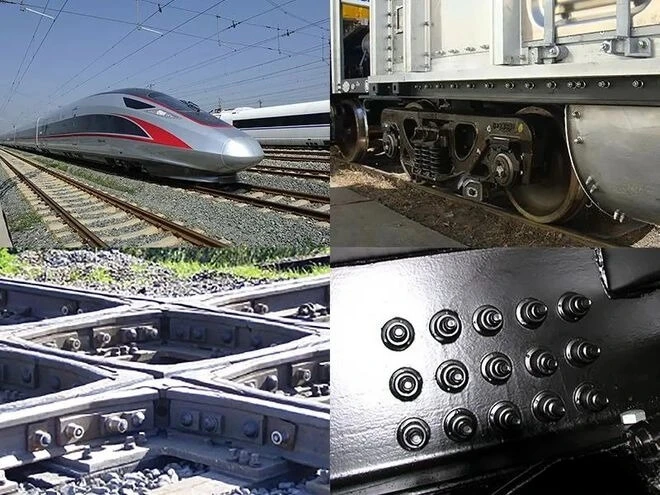

Steel Pop Rivets for Railroads

Incredibly, carbon steel blind rivets are also used to connect railroad cars. This is because the Carbon Steel Blind Rivets are able to withstand the severe vibrations and loads that are generated during train operations. In addition to this

In addition to this, the frames, chassis and door frames of the railroad cars are also connected using steel blind rivets.

Are Steel Rivets Stronger than Aluminum Rivets?

| Comparison Factor | Steel Rivets | Aluminum Rivets |

| Tensile Strength | High, ideal for high load and strong fastening | Low, suitable for lightweight and moderate-strength applications |

| Shear Strength | High, suitable for high shear stress applications | Lower, suited for moderate shear stress environments |

| Material Hardness | High hardness, good wear resistance for abrasive environments | Low hardness, suitable for softer materials |

| Weight | Heavier, not ideal for weight-sensitive designs | Lightweight, ideal for weight-sensitive applications |

| Corrosion Resistance | Low, requires galvanizing or surface treatment to improve corrosion resistance | Naturally corrosion-resistant, requires no additional treatment |

| Durability | High durability, suitable for long-term heavy loads and vibration environments | Less durable, ideal for light and moderate load applications |

| Cost | Higher, especially with corrosion protection | Relatively lower, more economical material and processing costs |

| Service Life | Long service life, especially under heavy load and vibration | Shorter lifespan, particularly in high-stress and heavy load environments |

| Vibration Performance | Excellent, ideal for dynamic loads and vibration | Poor, may loosen or fail in prolonged vibration |

| Typical Applications | Construction, bridges, heavy machinery, steel structures, transportation facilities | Aerospace, automotive bodies, electronics, household appliances |

What Are the Quality Standards for Carbon Steel Blind Rivets?

The quality standards of Carbon Steel Blind Rivets directly impact the safety and consistency of connections. As a professional manufacturer, Rivmate produces carbon steel blind rivets in strict compliance with internationally recognized quality and dimensional specifications, ensuring product reliability across diverse markets and applications.

During production and inspection, Rivmate primarily references and implements international and industry standards such as ISO, DIN 7337, and IFI 114. These standards specify precise requirements for rivet dimensional tolerances, material properties, and mechanical strength. Simultaneously, our product design and performance align with the technical specifications of internationally renowned brands like HUCK and Avdel, meeting the demands for high strength and consistent performance in critical applications.

How Do You Ensure lot-to-lot Consistency of Your Carbon Steel Pop Rivets?

To ensure consistent dimensions and performance of Carbon Steel Pop Rivets across different batches, Rivmate—as one of China’s leading pop rivet manufacturers—has established a systematic, traceable quality management process.

- Controlled Raw Material Sourcing: Raw materials are sourced exclusively from certified suppliers. Composition and performance are verified prior to acceptance to ensure stable and reliable base materials.

- Standardized Production Processes: Unified process parameters and operational specifications are established. Critical operations are controlled to minimize human variation.

- Automated Production Equipment: Automated machinery completes key forming processes. This enhances dimensional accuracy and batch stability.

- IATF 16949 Quality System: Operates the quality management system in compliance with IATF 16949 requirements. Continuously monitors and improves processes and outcomes.

- Batch Sampling Inspection: Conducts sampling inspections for each production batch. Focuses on verifying dimensions, tolerances, and mechanical properties.

- Batch Documentation and Traceability: Maintains comprehensive batch records. Enables full traceability from raw materials to finished products.

Materials Commonly Used in the Manufacture of Carbon Steel Pop Rivets

Carbon Steel is typically categorized into the following major types based on carbon content, with each type directly influencing the strength, toughness, and applicable scenarios of blind rivets:

Mild Steel (Low Carbon Steel)

Typically contains 0.04%–0.25% carbon. Low-carbon steel offers excellent plasticity and formability, resulting in blind rivets that are easier to install and relatively cost-effective. Low-carbon steel blind rivets are commonly used in low-strength applications such as thin sheet metal connections and general sheet metal assembly—scenarios where load-bearing requirements are low but installation efficiency is prioritized.

Medium Carbon Steel

Features higher carbon content than low-carbon steel, delivering significantly enhanced strength and hardness. Blind rivets made from this material are suitable for medium-load applications, offering a favorable balance between strength and toughness.

High Carbon Steel

Features the highest carbon content, delivering superior hardness and tensile strength. Corresponding blind rivets are commonly used for high-strength structural connections, though they demand more rigorous manufacturing and installation techniques.

Alloy Carbon Steel

By adding other alloying elements to carbon steel, strength, wear resistance, or fatigue resistance can be further enhanced. Alloy carbon steel blind rivets are primarily used in demanding conditions, such as rail connections, critical automotive components, and heavy-duty industrial equipment.

In summary, low-carbon steel blind rivets are better suited for light-load and thin-sheet applications, while medium-carbon, high-carbon, and alloy carbon steel blind rivets are widely used in structural scenarios demanding higher strength and reliability. When selecting rivets for practical applications, comprehensive evaluation based on load conditions, material thickness, and operating environment is essential.

Does the Tensile Strength and Shear Strength of Carbon Steel Blind Rivets Meet the Requirements?

Before selecting Blind Rivets, Blind Rivet Shear Strength and Blind Rivet Pullout Strength / Tensile Strength are two core performance metrics that businesses and engineers must prioritize. These parameters directly determine the safety and stability of the connection under load and during long-term use.

Qualified and stable shear and pullout strengths significantly reduce the risk of structural failure. In practical engineering, this translates to fewer instances of loosening, breakage, or rework issues. Long-term, it effectively lowers maintenance and rework costs, delivering substantial overall cost savings for projects.

To validate product performance, the video demonstrates our laboratory strength testing process for Lockbolt Rivets. By quantifying key mechanical properties through standardized testing methods, we provide reliable data for product selection and application. We hope these test results assist your project decision-making.

As a Rivet Manufacturer, What is Your Delivery Capacity?

As a professional pop rivet manufacturer, delivery capacity is one of the key factors customers prioritize when selecting suppliers. Stable, predictable lead times directly impact project schedules and supply chain security.

As China’s leading pop rivet manufacturer, we have established a comprehensive production and planning system, enabling sustained, high-volume delivery capabilities. Regardless of order size—from routine batches to project-level large orders—we complete production and delivery within mutually agreed-upon timelines.

In production management, we ensure stable and controllable production rhythms through standardized processes, optimized capacity allocation, and automation of critical operations. Even during industry peak delivery periods, we execute according to established plans, preventing production fluctuations from disrupting customers’ assembly and shipping schedules.

Simultaneously, our mature raw material supply system and inventory management mechanisms enable us to effectively respond to demand fluctuations, minimizing delays caused by material shortages or scheduling issues.

Choosing us means choosing reliable delivery assurance and long-term, stable supply capabilities, empowering your project execution with greater confidence and control.

How Much Production Capacity Do You Have?

As one of China’s leading hollow rivet manufacturers, Rivmate’s production capacity has been consistently validated by the market and our customers, enabling us to reliably support large-scale, sustained order demands.

In terms of production capacity, we maintain a comprehensive production line layout and mature process systems, achieving a monthly output exceeding 1 billion rivets. This scale allows us to simultaneously serve multiple major project clients without compromising delivery reliability. Among our existing client base, long-term customers with annual procurement exceeding ten million RMB are commonplace—a testament to our production capacity and delivery reliability.

From a supply chain management perspective, Rivmate ensures production execution according to schedule even during peak order periods through stable raw material sourcing, rational production planning, and automation of critical processes. Large orders never compromise delivery resources for smaller ones, as maintaining controllable lead times remains our fundamental principle.

Therefore, whether you require a one-time bulk project purchase or a long-term, stable annual framework order, Rivmate possesses sufficient production capacity and experience to deliver on time. Choosing us means your production schedule won’t be disrupted by rivet supply issues.

Are There Price Discounts for Bulk Purchases?

Sure. If you have a large number of orders, we can purchase large quantities of raw materials at once, which will reduce the cost of production. That’s why we usually give a price discount for bulk purchases, which will save you a lot of financial costs.

Do You Offer Customized Value-added Services?

Yes, we offer customized value-added services to help clients reduce overall costs, enhance sales efficiency, and shorten time-to-market. These services are particularly suited for distributors, brand owners, and long-term project clients.

Customized Packaging

We provide bespoke packaging solutions tailored to your market and channel requirements, including branded packaging, retail packaging, or project-specific packaging. This enables goods to enter sales or assembly immediately upon arrival, reducing labor and time costs associated with secondary packaging.

Customized Rivet Logo Service

Supports custom client branding on rivets or related packaging, enhancing brand recognition and channel differentiation while boosting product professionalism and market visibility.

These value-added services typically incur only minimal additional fees, yet significantly reduce storage, labor, and reprocessing costs in actual operations. For most clients, this represents an effective way to achieve higher efficiency and faster cash flow with a modest investment.

If you require products ready for immediate sale or deployment upon arrival, our customized value-added services are the ideal solution. We welcome you to discuss your specific requirements with us.

Do You Provide Technical Support When I Purchase Carbon Steel Blind Rivets?

If you’re advancing a project but unsure how to select the right blind rivet for your specific application, this is a very common scenario. The diameter, length, clamping range, material, and head type of the rivet all directly impact assembly strength and long-term reliability. Improper selection often leads to rework and additional costs.

Our engineering team offers expert technical support. Whether recommending suitable rivet specifications for your application or assisting with evaluations of shear strength, pull-out strength, and real-world installation performance, we provide clear, actionable advice based on engineering expertise. For projects requiring validation, we can also supply relevant performance data and application references to help mitigate selection risks.

If you have any questions about Steel Blind Rivets or other riveting solutions, please feel free to contact us anytime. From selection guidance to application solutions, our engineers will support your project decisions throughout the process, ensuring the rivets truly meet your practical requirements.

Can You Provide Technical Data Sheets for Materials and Properties?

Our Sample Book provides a comprehensive list of key technical parameters for all types of blind rivets, designed to assist engineers and procurement personnel in accurate selection. These parameters directly impact rivet installation compatibility, joint strength, and long-term reliability.

The Sample Book typically includes the following core information:

- Rivet Diameter: Determines basic load-bearing capacity and hole size.

- Rivet Size: Enables quick model identification and application scope.

- Rivet Body Length: Influences back-side forming results.

- Rivet Grip Range: Defines the total thickness range of connectable materials.

- Drill (Recommended Hole Diameter): Ensures stable and consistent installation.

- Mandrel Dia (Mandrel Diameter): Relates to forming force during the riveting process.

- Mandrel Reveal (Mandrel Residual Height): Affects appearance and assembly safety.

- Tensile Strength: Evaluates axial load capacity.

- Shear Strength: Evaluates lateral load capacity.

For easier comprehension and comparison, the following section uses Carbon Steel Monobolt Rivets as an example to detail corresponding technical parameters and their engineering significance, aiding in intuitive selection and application evaluation.

| Size | d (mm) | k (mm) | L (mm) | dk (mm) | P (mm) | dm (mm) | Hole Dia (mm) | Grip Range (mm) | Tensile (N) | Shear (N) | Breaking Load (N) | Retention Load (N) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.8×10 | 4.70–4.80 | 2.1 | 18.2 | 10.1 | 27 | 3.1 | 4.9–5.1 | 1.6–6.9 | 5110 | 6440 | 7500 | 600 |

| 4.8×14 | 4.70–4.80 | 2.1 | 24.5 | 10.1 | 27 | 3.1 | 4.9–5.1 | 1.6–11.0 | 5110 | 6440 | 7500 | 600 |

| 6.4×14 | 6.40–6.58 | 2.9 | 23.7 | 13.4 | 33 | 4.1 | 6.7–7.0 | 2.1–9.5 | 10450 | 11780 | 12500 | 1100 |

| 6.4×19 | 6.40–6.58 | 2.9 | 33.0 | 13.4 | 33 | 4.1 | 6.7–7.0 | 2.1–15.8 | 10450 | 11780 | 12500 | 1100 |

| 9.8×21.3 | 9.65–9.90 | 4.1 | 36.2 | 20.3 | 32 | 6.1 | 10.0–10.4 | 3.0–15.9 | 14850 | 23730 | — | — |

Is it Possible for You to Have a Stocking Program?

Yes, we can provide a Stocking Program, which is one of our key service capabilities as a professional blind rivet manufacturer.

Leveraging thousands of square meters of dedicated warehouse space, we maintain ample stock of standard models and commonly used specifications for our customers. For pop rivet types with stable market demand and high usage frequency, customers can achieve rapid shipment, effectively shortening lead times and reducing supply risks associated with emergency procurement.

Additionally, we support customized stocking plans tailored to customer requirements. Based on your annual consumption, project timelines, and safety stock requirements, we can pre-schedule production and manage inventory accordingly. This approach ensures continuous supply, minimizes stockout risks, and enhances overall supply chain efficiency.

Through our hybrid model combining standard inventory with customized stocking, we deliver greater flexibility in meeting diverse customer delivery requirements. Whether for routine expedited shipments or stable supply for long-term projects, we provide reliable support, empowering customers to advance their production and delivery schedules with confidence.

Wholesale Steel Blind Rivets from China Factory

Wholesale high strength steel pop rivets from China pop rivet manufacturer. Here the benefits are believed to be clear to you. You can get the best cost performance by importing steel pop rivets from China. Whether it is quality or price, you will get the best.

Request a quote or get a sample today!

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!