Table of Contents

How Strong are Pop Rivets? I believe this is a concern for many people. The strength of a blind rivet is very important for use. Through this article, you will learn HOW STRONG ARE POP RIVETS, what makes up the strength of a blind rivet, how to provide blind rivet strength and how to choose the right rivet strength.

Table of Contents

What is the Load Capacity of Blind Rivets?

The amount of load carrying capacity of a blind rivet is related to several factors.

- Rivet Material

- Rivet Size

- Installation method

- Type of material being joined

- The environment in which it will be used

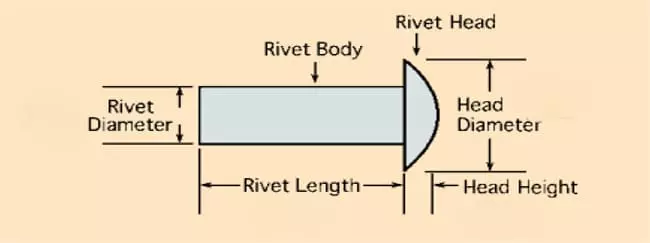

Rivet Size

The diameter of a blind rivet directly affects its load carrying capacity. Obviously, the larger the diameter of the rivet, the greater the load carrying capacity.

In addition to this, the length of the rivet (or “grip range”) also affects its load carrying capacity. Longer rivets are better suited for joining thicker materials and generally provide higher tensile strength.

Installation Method

The tools used for installation and the pressure they generate are critical to the strength of the rivet. Correct installation ensures that the rivets have the load carrying capacity for which they were designed, whereas improper installation (e.g., over-tightening or uneven pressure application) can result in reduced strength.

Rivet Materials

Load carrying capacity of Blind Rivets of different materials

| Rivet Type | Tensile Strength | Shear Strength | Suitable Materials |

| Aluminum Rivet | Approximately 400-500 kgf (880-1100 lbf) | Approximately 250-300 kgf (550-660 lbf) | Suitable for light structures or thin materials |

| Stainless Steel Rivet | Approximately 800-1200 kgf (1760-2640 lbf) | Approximately 600-900 kgf (1320-1980 lbf) | Suitable for high strength or corrosive environments |

| Steel Rivet | Approximately 1500 kgf (3300 lbf) | Approximately 1000 kgf (2200 lbf) | Suitable for heavy-duty structures or high-load scenarios |

Important Tips:

- Tensile Strength: refers to the maximum tensile force that the rivet can withstand in the axial direction.

- Shear Strength : refers to the maximum transverse shear force on the rivet.

Calculation of load-bearing capacity

In order to estimate the load carrying capacity of a blind rivet, calculations can be based on the following formulas, although these calculations are usually performed by a professional engineer for specific application conditions:

- Tensile force = Strength of the rivet material × Area of breakage of the rivet.

- Shear force = shear strength of the rivet material × shear area.

How Strong are Blind Rivets Compared to Other Rivet Types?

The strength of Blind Rivets compared to other rivet types depends primarily on their design features, material, diameter and application scenario. The following is an analysis of Blind Rivets compared to other rivet types such as Solid Rivets, Semi-Hollow Rivets and Self-Pierce Rivets:

Blind Rivets vs Solid Rivets

Blind rivets can be installed from one side, while solid rivets must be operated from both sides. Also, blind rivets can be used to join multiple layers of material.

However, the strength of blind rivets is lower than that of solid rivets. Solid rivets usually have high tensile and shear strengths because they are more compact. While the interior of a blind rivet is hollow, its shear and tensile strength is lower than that of a solid rivet.

Blind Rivets vs Semi Hollow Rivets

A semi-hollow rivet will completely deform and seal at the end, but it is weaker. In high vibration or shock environments, semi-hollow rivets are more resistant to loosening.

Do You Have Any Questions?

Let Us Solve Your Problem

| Rivet Type | Tensile Strength | Shear Strength | Applicable Scenarios |

| Blind Rivet | Moderate, suitable for light loads | Moderate, suitable for light loads | Metal sheets, plastic panels, lightweight structures |

| Solid Rivet | High, suitable for heavy loads | High, suitable for heavy loads | Aerospace, bridges, mechanical structures |

| Semi-Hollow Rivet | Moderate to high, suitable for dynamic loads | High, suitable for vibration environments | Automotive components (brake pads, suspension systems) |

How to Choose Pop Rivets Strength?

It is not correct for the product to have pop rivets that are too strong or too weak. Only the optimum strength of the pop rivet is critical to ensure a strong, safe and long term stable riveted joint. So how do you choose the right strength of pop rivets?

1. Determine Application Requirements

- Tensile Strength: The tensile strength of the blind rivet must meet the needs of the connected parts under axial tension. If the riveted connection is primarily subjected to tensile forces, select a high tensile strength blind rivet, such as steel or stainless steel.

- Shear Strength: If the riveted joint is primarily subjected to lateral shear, select rivets with high shear strength.

2. Selection According to the Working Environment

- Corrosive environments: If riveted parts are exposed to corrosive environments (e.g., marine, high humidity areas), select stainless steel or galvanized rivets for corrosion resistance.

- Temperature environments: High or low temperature environment may affect the performance of rivets, choose materials suitable for temperature changes (such as stainless steel or special alloy rivets).

- Vibration and dynamic loads: In vibration environments, select high-strength and anti-loosening performance of the blind rivets, such as rivets with locking structure (such as structural blind rivets).

| Application Scenario | Material Type | Rivet Material | Recommended Diameter | Recommended Length | Environmental Requirements |

| Light Equipment Assembly | Aluminum Alloy | Aluminum Rivet | 3.2mm | 6-8mm | No special environmental requirements |

| Automotive Parts (High Vibration Environment) | Steel or Aluminum | Stainless Steel Rivet | 4.8mm | 10-12mm | Vibration resistance, corrosion resistance |

| Mechanical Equipment Connections | Carbon Steel | Carbon Steel Rivet | 6.4mm | 12-16mm | Heavy load, high strength |

| Marine Engineering Devices | Stainless Steel | Stainless Steel Rivet | 4.8mm | 8-10mm | High corrosion environment |

3. Determine the Rivet Material

Rivets made of different materials have different strength ratings:

- Aluminum Pop rivets: light weight, suitable for light load applications, good corrosion resistance.

- Stainless steel pop rivets: high strength, good corrosion resistance, suitable for high loads and harsh environments.

- Carbon steel pop rivets: high strength, suitable for industrial and mechanical heavy-duty scenarios.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Improve the Strength of Blind Rivets?

Methods to improve the strength of blind rivets typically involve optimizing the material, design and installation process. The following are some common ways to improve the strength of blind rivets.

1. Selection of High Strength Materials

The primary factor affecting the strength of a blind rivet is the material used to make the rivet. The strengths of commonly used metal materials are listed below in descending order:

Carbon Steel > Stainless Steel > Aluminum

2. Increase Rivet Diameter and Length

Increasing the diameter of the rivet can significantly increase its strength. In general, the larger the rivet diameter, the greater its tensile, shear and durability properties will be. Therefore, you can choose a larger diameter to enhance the overall strength of the connection.

The correct rivet length ensures that it holds the thicker material tightly, thus increasing its tensile strength.

3. Optimized Rivet Head Design

Common head shapes for blind rivets are dome head, large flange head and countersunk head. the larger the head, the stronger the riveted joint.

In addition, some structural rivets have a self-locking design inside the head, which can further increase their strength.

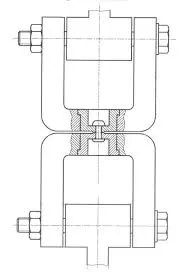

How to Test the Blind Rivet Strength?

Strength testing of blind rivets is a critical step in ensuring that blind rivets will perform as intended in the application. Common test methods include physical testing and engineering calculations. Of course, there is no way to bypass the following steps when testing the strength of a blind rivet:

- Tensile Test

- Sheat Test

- Peel Test

- Peel Shear Test

- Fatigue Test

- Vibration Test

- Thermal Cycling Test

- Torque Test

- Installation Test

Wholesale Strong Pop Rivets for Your Project

Blind rivet strength is critical. Through this blog, you have clearly understood how strong are pop rivets. If your project requires high strength of blind rivets, please contact us! Rivmate is the top rivet manufacturer in China, which can provide you with blind rivets of any strength.

Get rivet samples for testing today!