Blind Rivet vs Solid Rivet: Which Rivet is Best for Your Business

Table of Contents

What are the fundamental differences between Blind Rivet and Solid Rivet? What are the specific differences in terms of strength and installation methods? Different types of rivets directly affect the structural lifespan, safety, and production cost. Blind Rivet is a single-side installation blind riveting structure, while Solid Rivet is the most typical types of aircraft rivets in the aviation field, renowned for its extremely high fatigue life. As Rivmate, with the ability for structural testing and experience in aviation-grade rivets, we will provide professional assistance to help you make the right choice.

Understanding Blind Rivets and Solid Rivets

Before comparing blind rivet vs solid rivet, it is necessary to first understand the structural essence and installation methods of the two types of rivets. The working principles of the two types of rivets are completely different, and therefore their applicable scenarios also have significant differences.

What Are Blind Rivets?

Blind rivets are a type of riveting method that can be installed on only one side. They consist of a cap body and a mandrel. During installation, the mandrel is pulled backward by a riveting gun, causing the tail of the cap body to expand and clamp the material. Because the construction workers only need to touch one side of the riveted components, blind rivets are particularly suitable for enclosed cavities, back areas that are inaccessible, or thin plate structures that require rapid batch assembly.

Blind rivets are widely used in lightweight structures such as sheet metal, appliance shells, vehicle interiors, and HVAC equipment. They have a simple structure, stable installation, and controllable cost, and are one of the most commonly used riveting methods in modern manufacturing.

What Are Solid Rivets?

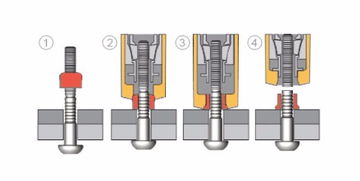

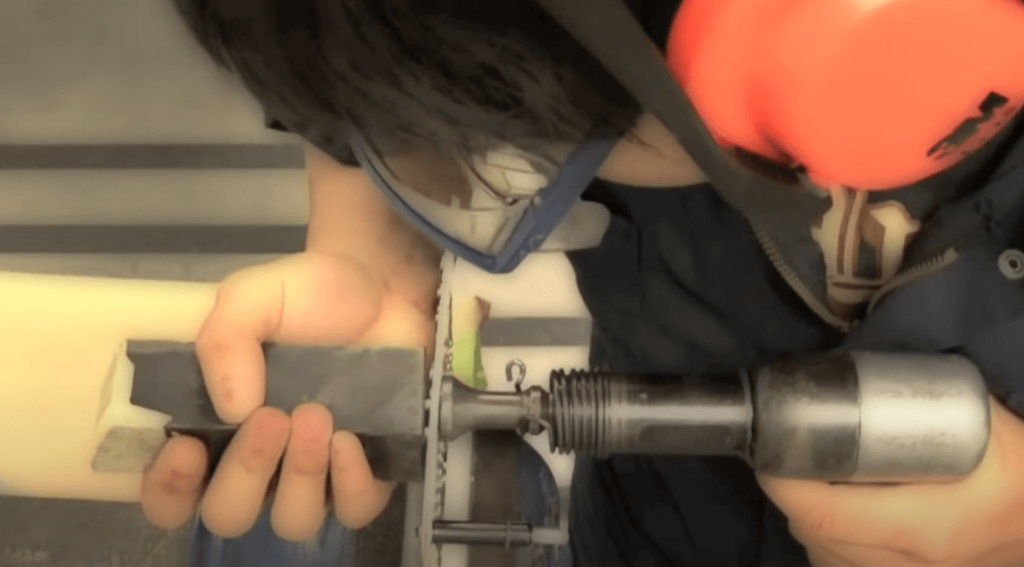

A solid rivet consists of a complete metal rod and a rivet head. It is the most traditional and structurally strongest type of rivet. During installation, it requires dual operations: one side applies impact or compressive force, while the other side uses an anti-rivet block for support, causing the rivet tail to undergo plastic deformation and form a locking shape. Due to the fact that this “forging” method can achieve extremely high strength and consistency, Solid Rivet is widely used in aircraft fuselages, wing structures, bridge connections, railway vehicles, and heavy machinery.

Its fatigue resistance ranks among the best among all types of rivets, and it is one of the most important fastening technologies in the aviation industry.

How They Work: Blind Rivet vs Solid Rivet

Understanding the structural differences between the two types of riveting methods is crucial for determining which one is more suitable for your project. There are fundamental differences in installation methods, back-forming methods, and final structural performance between the two.

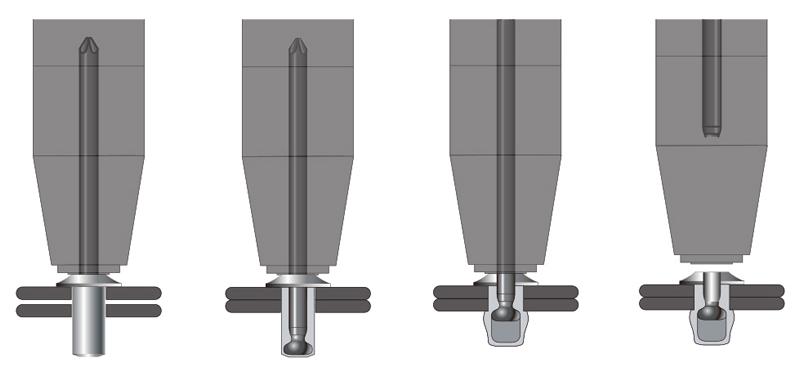

Blind rivets are fastened by the expansion force generated when the core shaft is pulled. During installation, the core shaft is pulled backward, causing the tail of the cap body to undergo plastic deformation, forming a stable “mushroom-shaped” expansion structure. This structure firmly clamps two or more pieces of material together. Its key features include:

- Single-side installation, suitable for structures where the back side cannot be accessed.

- No need for high-temperature construction, will not affect the heat treatment state of the material.

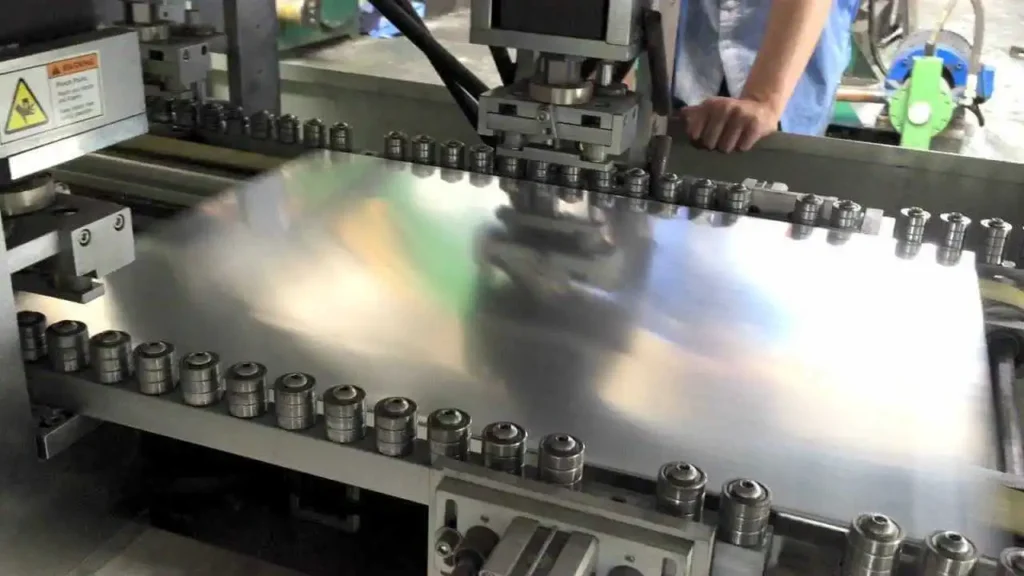

- Installation is fast and can be achieved through batch automation.

Therefore, blind rivets are widely used in industries such as sheet metal, HVAC, automotive parts, and home appliance casings.

Solid Rivet Working Principle

Solid rivets undergo plastic deformation of the rivet tail through external force hammering or the compression of an air-powered riveting gun. After the rivet tail is “molded”, a very tight and consolidated head is formed, with extremely high structural strength. Its characteristics include:

- The construction must be carried out simultaneously on both the front and rear sides (hammering on one side, buckling on the other).

- The deformation of the rivet tail is a process of metal cold forging, which can significantly enhance the fatigue resistance.

- It is suitable for structures that can withstand high shear, high vibration, and high fatigue loads.

Therefore, solid rivets are the standard solution for high-load structures such as aircraft structures, bridges, vehicle side beams, and fuselage skins.

Differences Between Solid and Blind Rivets

In the discussion of “Blind Rivet vs Solid Rivet”, the performance differences are the aspect that users are most concerned about and has the highest search weight. There are significant differences between the two in terms of structural strength, fatigue life, waterproofing ability, vibration resistance performance, and process consistency. The following is the core comparison explanation.

Structural Performance Comparison: Solid Rivet vs Blind Rivet

| Performance Aspect | Blind Rivet | Solid Rivet |

|---|---|---|

| Shear Strength | Medium to High | Very High (Aerospace Grade) |

| Tensile Strength | Moderate | Extremely High |

| Vibration Resistance | High | Excellent (Plastic deformation provides damping) |

| Fatigue Life | Good | Best in the industry |

| Waterproof Capability | Closed-end type can be fully sealed | Requires additional sealant |

| Weight Impact | Lightweight (available in aluminum) | Slightly heavier |

| Process Consistency | High, easy to standardize | Highly dependent on worker skill and technique |

1. Shear Strength

The shear resistance performance of Blind Rivet falls under the category of medium to high level, which can meet most industrial requirements such as sheet metal, mechanical enclosures, and roofing. However, its expansion locking structure limits the maximum load-bearing capacity.

Solid Rivet achieves overall integration through the cold forging deformation of the metal at the rivet tail. Its shear strength can reach the highest level in the industry. Therefore, it is widely used in aviation, rail transportation and structural frameworks.

The shear strength of solid rivets is 45–60% higher than that of blind rivets under the same diameter conditions.

The tensile strength of Blind Rivet mainly relies on the residual core shaft and the side wall support, thus it is rated as “medium level”. Solid Rivet, on the other hand, forms a single metallic unit and has a stronger tensile capacity, especially suitable for withstanding cyclic tensile or impact loads. The tensile strength of solid rivets is approximately 1.5–2 times that of blind rivets.

3. Vibration Resistance

Blind rivets have excellent vibration resistance properties, especially for structural blind rivets. However, Solid Rivet, due to its more thorough tail deformation and more uniform force distribution at the joint surface, can maintain extremely high stability in high-vibration environments.

The strong vibration areas such as the skin of the aircraft wing and the main beam joints have long confirmed the advantages of solid rivets.

4. Fatigue Life

The fatigue life of Blind Rivet is excellent and it is suitable for regular vibration or light-load conditions. Solid Rivet, on the other hand, is almost the “ceiling” of fatigue life in the industrial field. Thanks to its forged structural shape, it has no internal voids and the load distribution is extremely uniform.

The lifespan of solid rivets in high-frequency fatigue tests is approximately more than three times that of blind rivets.

The Closed-End Blind Rivet can achieve 100% sealing, which is its significant advantage. However, the Solid Rivet itself does not have a sealing function. If used in a sealing structure, additional sealant, adhesive layer, or special sealing sheet needs to be used. In scenarios such as HVAC, roofing, and exterior walls, the closed-end blind rivet is significantly more advantageous.

6. Weight Consideration

Blind rivets can be made of lightweight materials such as aluminum, stainless steel, and copper, resulting in a significantly lower overall weight. Solid rivets usually use aluminum alloy or steel, but due to their denser structure, they will slightly increase in weight. For the lightweight requirements of aviation or transportation equipment, a comprehensive balance needs to be achieved based on the specific conditions.

Why Are Blind Rivets Installed in Lieu of Solid Rivets?

If you’re an engineer, you’ll find that pop rivets are much more likely to show up in real industrial applications than solid rivets. Although a blind rivet is not as strong as a solid rivet, it can still provide a stable and strong connection.

So why do engineers prefer to use blind rivets over solid rivets? Because a blind rivet offers many advantages that a solid rivet does not.

Accessibility

The use of blind rivets is a reliable solution when access to the back side of the material being joined is not possible or difficult. Blind rivets can be installed from one side only, eliminating the need for backside access.

Efficiency and Speed

Blind rivets offer a faster and more efficient installation process than solid rivets. They can be installed quickly using specialised tools, reducing total assembly time. In high-volume production environments, saving time is critical to productivity.

Ease of Installation

Blind rivets are relatively easy to install and require less skill and training.

Cost-effectiveness

Blind rivets are more cost-effective than solid rivets. Fewer tools and equipment are required to install blind rivets, reducing initial investment costs. In addition, blind rivets typically have lower material costs.

Vibration Resistance

Blind rivets have good resistance to vibration. The rivet core inside the blind rivet expands and grips the material tightly, reducing the likelihood of loosening or failure caused by vibration or dynamic loading.

How to Choose Between Solid Rivets and Blind Rivets

a. Strength Requirements

Solid rivets are a better choice if your project’s strength requirements are very high, requiring maximum strength and structural integrity. For example, application scenarios such as wings, tails, etc. of aircraft in the aerospace industry.

Blind Rivets are mainly used for joining thin sheet materials, especially in applications where it is necessary to maintain a flat surface in the joint. Examples include automotive body assemblies, thin body panels, doors and other components. Shells and panels for avionics, joining of thin metal sheets, etc.

b. Workspace

The great thing about blind rivets is that they can be installed with access to only one side of the material. So if your project has limited access space and you need to complete the entire installation process on one side, then a blind rivet is best for your project! You can look directly to the blind rivet manufacturer and they will give you a professional recommendation!

Solid rivets are required to be accessible on both sides for installation. So if you have a project that is fully accessible on both sides and requires a great deal of strength, then you should choose solid rivets for your project. This is the optimal choice!

c. Cost Considerations

You need to figure out what your project budget is. Blind rivets are typically more cost effective as they have a lower material cost and require fewer tools for installation. Solid rivets may have a higher material cost and require special tools and skilled labour for installation, which may increase the total cost.

d. Vibration Resistance

If your application is subject to vibration or dynamic loads, then you need to consider the vibration resistance of the type of rivet you choose. Blind rivets are designed to make a stable connection through expansion, so they have good resistance to performance under vibration and are able to grip the material firmly. If this is a requirement for your project then solid rivets are not suitable to be chosen!

How to Find the Right Rivets

Choosing between Blind Rivet and Solid Rivet essentially depends on the structural requirements, installation environment and safety level. As a Rivmate engineering specialist who has been involved in structural connection testing for a long time, I suggest making the judgment based on the following four most critical dimensions:

1. If you are looking for fast installation speed, high assembly efficiency and low cost → Choose Blind Rivet

Blind rivets do not need to contact the back side and can be installed on one side in a narrow space. The construction speed is 2-4 times that of traditional solid rivets. The equipment requirements are low, the installation consistency is strong, and it is suitable for batch production scenarios. Especially applicable to: home appliance shells, thin sheet metal, building curtain walls, metal edge pieces. Its cost advantage is obvious, and it is the preferred solution for most OEM factories.

2. If you are seeking extremely high structural strength, fatigue life and safety level → Choose Solid Rivet

Solid rivets achieve an integrated metal connection through plastic deformation, offering top-level structural reliability. Their shear, tensile, and fatigue resistance are significantly superior to blind rivets. They are particularly suitable for:

- Aviation structures (airframe, wing skins)

- Heavy machinery equipment

- Bridges or load-bearing structures

- High cyclic fatigue environment

If the project involves safety levels, impact, or long-term vibration, Solid Rivet is a more reliable choice.

3. If single-sided installation, closed structure or on-site construction is required → Prefer Blind Rivet

Many applications cannot reach the back side, such as closed steel pipes and profile cavities. At this point, Solid Rivet cannot be used for construction, while Blind Rivet offers a perfect solution. The closed-end type can also achieve waterproof and airtight sealing.

4. If used in aviation, rail transportation, or heavy machinery structures → Must use Solid Rivet

These industries have strict requirements for structural integrity and fatigue life. The metal continuity and plastic deformation characteristics of Solid Rivet are essential for meeting safety standards. Rivmate suggests:

- Aircraft skin → Solid aluminum rivets (such as 2117-T4)

- Heavy-duty steel structure → Solid steel or stainless steel rivets

- Railway vehicles → High-strength structural solid rivets

Get the Right Rivet Solution for Your Project

The difference between blind rivets and solid rivets lies fundamentally in their installation methods, structural strength, and applicable scenarios. Blind rivets are suitable for single-side installation, thin plate structures, and high-efficiency production; while solid rivets have an absolute advantage in terms of strength, fatigue life, and safety level, and are the standard choice in the aviation and heavy industry sectors.

If you are choosing the appropriate riveting method for your project, the Rivmate engineering team can offer you:

- Free samples

- Material and thickness matching suggestions

- Strength and fatigue life assessment

- Customized riveting solutions

Please feel free to contact us to obtain the Rivmate connection solution that is most suitable for your business.

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met