Table of Contents

Riveting is a mechanical connection. It provides a stable connection, so is riveting permanent or temporary?

By reading this guide, you will know clearly understand this question. Including the difference between permanent and temporary connections, applications of riveting as a permanent connection.

Table of Contents

What is Riveting?

Riveting form a locking structure by plastic deformation of the rivet, which cannot be separated in a non-destructive way after joining. Riveting is categorized into cold riveting and hot riveting. After the development of mechanization, pneumatic riveting gradually replace manual operation. Rivets are usually considered permanent connections. If you want to remove rivets, the only way to do so is by cutting or drilling.

Cold riveting is limited by the hardness and diameter of the material (usually ≤8mm); while hot riveting is more expensive due to the need for heating equipment. Rivets are usually considered permanent connections. If you want to remove a rivet, the only way to do so is by cutting or drilling.

Permanent Connection vs Temporary Connection

Permanect connection: basic concept

A permanent joint is a type of irreversible connection in mechanical engineering, where destructive operations are required to separate the parts after joining. It is used in industrial design for connection strength, sealing or long-term stability of the higher requirements of the scene, such as aerospace, automotive industry, building structures. Typical forms include Riveting, Welding, Adhesive Bonding and Press Fit.

temporary connection: basic concept

A temporary connection is a connection in mechanical engineering that allows for non-destructive disassembly and reusability, usually through mechanical forces (e.g., friction or threaded occlusion) to realize the fixation of components. It is widely used in scenarios that require frequent adjustments, maintenance or modular design, such as equipment assembly, maintenance and debugging, and test system construction. Typical forms include Bolts, Screws, Clamps, Pins and Snap-fits.

Permanent Connection vs Temporary Connection

| Comparison Aspect | Permanent Connections (Riveting, Welding, Adhesive Bonding) | Temporary Connections (Bolts, Screws, Clamps) |

| Disassembly | Requires destructive methods (e.g., cutting rivets, grinding welds) | Non-destructive, reusable |

| Lifespan | Irreversible, long-term fix | Reversible, suitable for periodic adjustments |

| Mechanical Performance | ◾ Superior vibration/fatigue resistance◾ Rigid (no loosening) ◾ Better sealing | ◾ Preload-dependent (loosening risk) ◾ Stress concentrations ◾ Sealing requires gaskets |

| Process Complexity | ◾ Requires specialized tools (welders, riveters) ◾ Higher skill level | ◾ Simple tools (wrenches, screwdrivers) ◾ Standardized processes |

| Cost Efficiency | ◾ Lower initial cost (no dedicated fasteners) ◾ Higher maintenance cost | ◾ Higher component cost (bolts/nuts) ◾ Lower maintenance cost |

| Typical Applications | ◾ Long-term stability (bridges, aircraft fuselages, pressure vessels) ◾ High-vibration environments | ◾ Frequent disassembly (robotic fixtures, test beds) ◾ Modular assembly (furniture, electronics) |

| Examples | ◾ Aircraft fuselage riveting ◾ Structural steel welding ◾ Automotive exhaust press fits | ◾ Engine-to-frame bolting ◾ 3D-printed part assembly with screws ◾ CNC machine clamps |

| Sustainability | ◾ Hard to recycle due to destructive disassembly | ◾ Reusable components reduce waste |

Do You Have Any Questions?

Let Us Solve Your Problem

Is Riveting Permanent or Temporary?

In practice, riveted joints are permanent connections. The main reasons for this are as follows:

- Irreversibility: rivets in the installation through plastic deformation (such as nail head forging) to form a locking structure, once completed that can not be separated without damage.

- Destructive disassembly: Separation of riveted parts requires the destruction of the rivet itself or the part being connected (e.g. drilling, cutting).

- Designed for: Rivets are designed to provide permanent stability and excellent resistance to vibration.

- Process Characteristics: Both cold and hot rivets form a permanent joint by deformation, regardless of the type of rivet (solid rivet, blind rivet).

Application of riveting as a permanent connection

Riveting, as a classic permanent connection, occupies an irreplaceable position in several key areas due to its fatigue resistance, material compatibility and lack of thermal influence.

I. Aerospace

Large amounts of aluminum and titanium alloys are used in aircraft. These metals are sensitive to welding heat (which tends to cause embrittlement) and riveting produces no heat affected zone (HAZ). And the rivet array disperses vibration stresses for longer life. In addition to this, rivets can join dissimilar metal materials.

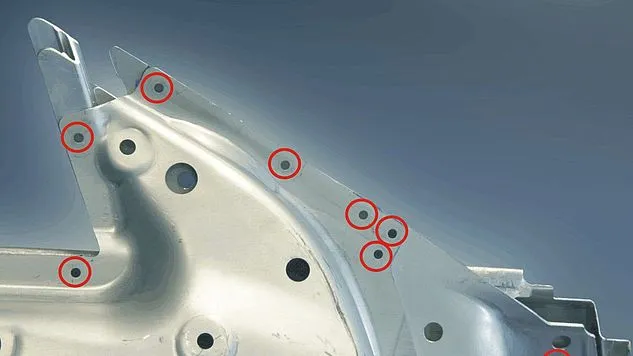

- Aircraft skin: aluminum alloy/composite fuselage panels riveted to the skeleton (e.g. Boeing 737 fuselage using hundreds of thousands of rivets).

- Engine nacelles: riveting high-temperature alloy components (e.g., titanium blade mounts).

- Spacecraft structures: lightweight aluminum honeycomb panels connected to frames.

II. Automobile manufacturing

Compared with welding, riveting does not generate electric arcs or sparks, making it suitable for battery packs and other components with high safety requirements. And SPR in riveting is ideal for automated scenarios. It does not require pre-drilling, and the word operation takes less than 0.5s, which is suitable for assembly line operation.

- Body-in-white frame: aluminum alloy frame mixed with steel plate riveted (e.g. Tesla Model Y using self-pierce riveting SPR).

- Battery pack shell: sealed riveted aluminum alloy shell of lithium battery pack (taking into account strength and explosion-proof).

- Roof and door: riveting of lightweight composite cover parts.

III. Construction

Buildings require high wind vibration resistance at connection points. And riveted nodes stress dispersion ability is better than bolts, reducing fatigue damage under long-term wind load. Sealed rivets prevent rainwater from penetrating into steel structure gaps.

- Steel bridge: steel truss node riveted (such as the early riveted structure of the Golden Gate Bridge in San Francisco).

- High-rise building facades: riveting of glass curtain walls to aluminum frames.

- Temporary structures: scaffolding connection nodes.

IV. Rail transportation

In rail transportation, the connected fasteners need to be under high-frequency vibration for a long period of time, and the riveted connection has better resistance to loosening than bolts. And riveted joints do not damage the material fireproof coating (welding high temperature may erode the protective layer).

- High-speed rail vehicle body: hybrid riveting of aluminum alloy frame and skin (combined with laser welding).

- Rail vehicle interior: riveted fixing of fireproof sound insulation boards.

- Subway doors: mechanical riveting of lightweight composite doors.

Do You Have Any Questions?

Let Us Solve Your Problem

Enhance Your Business with Rivmate

By reading this blog, I believe you have a clear understanding of “is riveting permanent or temporanry”. The removal of rivets requires the destruction of the original structure of the rivet, so riveting is a permanent connection. Riveting can provide a lightweight, stable connection to your project.

If you want to make your business more successful, contact us for professional riveting solutions.