What are Countersunk Blind Rivets Used for?

Table of Contents

In modern industrial assembly, countersunk blind rivets play an irreplaceable role. They are a type of single-sided installation rivet with a countersunk head design. After installation, the rivet head is flush with the surface of the workpiece, without any protrusion. This structure not only ensures a smooth and aesthetically pleasing appearance but also reduces air resistance or friction interference, making it particularly suitable for products that require streamlined designs or smooth surfaces. Due to the fact that installation only requires single-sided operation, countersunk blind rivets can quickly achieve reliable connections even when the backside of the structure is inaccessible.

The core value of countersunk blind rivets lies in their simultaneous fulfillment of both functionality and aesthetics. They ensure connection strength while keeping the surface free from obvious protrusions, thus avoiding issues such as scratches and jams. This is also the core concern of users when searching for this product – they want to know in which scenarios it is applicable, what structural advantages it has, and the key points to note when selecting.

Structure and Design of Countersunk Blind Rivets

Countersunk Head Design

Countersunk blind rivets feature a countersunk head structure, which becomes flush with the surface of the plate after installation. This design prevents surface protrusions, reduces the risk of scraping or interfering with moving parts, and enhances the aesthetic appeal of the finished product. It is commonly used in assembly scenarios where a smooth and flat appearance or a smooth touch is required.

Blind Riveting Principle

This type of rivet is based on the blind riveting connection principle and can be installed from a single side only, making it highly suitable for structures where double-sided access is not possible. The installation process is fast and repeatable, reducing the time required for workstation adjustments. This feature is particularly important in confined spaces, closed cavities, or special structural components.

Material Diversity

Countersunk blind rivets can be made of various materials such as aluminum, stainless steel, copper, and alloy steel. Aluminum is lightweight and suitable for equipment where weight reduction is a requirement; stainless steel has strong corrosion resistance and can be used for a long time in damp or chemical environments; copper has good electrical conductivity and antibacterial properties, making it suitable for electrical equipment and medical devices. According to statistics, the service life of stainless steel countersunk blind rivets in outdoor structural components can be 2 to 3 times longer than that of ordinary steel.

Product Advantages of Rivmate

Rivmate strictly controls the head forming accuracy of countersunk blind rivets to ensure that each rivet is flush with the surface of the plate after installation. At the same time, the stability of the clamping force is tested in batches to ensure the consistency of strength performance among different batches of products. This level of precision and stability can significantly reduce the rework rate, improve assembly quality, and meet the requirements of aviation, rail transit, and high-end industrial equipment.

Why Choose Countersunk Blind Rivets Instead of Ordinary Bolts?

a. Appearance and Functional Advantages

Countersunk Blind Rivets are installed so that their surface is flush with the panel surface, preventing protruding parts from scratching people or snagging items. They result in a neater appearance and are suitable for assembly where high visual quality is required, such as in appliance housings, display equipment, and decorative panels.

Compared with ordinary round-headed rivets, countersunk rivets can better balance functionality and aesthetics.

b. Aerodynamic and Fluid Dynamic Advantages

A smooth surface can reduce the disturbance of air or water flow. In high-speed or fluid environments such as aircraft structures, automotive exterior parts, and ship decks, countersunk designs can effectively reduce wind resistance and water resistance.

The data shows that in the application of high-speed running aircraft skins, the use of countersunk rivets can reduce the surface resistance by approximately 3%.

c. Safety and Durability

Without the protruding parts, the risk of nail loosening and coating damage caused by collision or friction can be reduced. This is particularly important in outdoor facilities, rail transit, and public facilities. Because it can extend the service life and reduce the maintenance frequency.

d. Comparison of Installation Effect with Standard Round Head Bolts

After installation, the heads of ordinary round-head rivets will protrude above the surface of the board, making them prone to becoming attachment points or concentrated force points. In contrast, Countersunk Blind Rivets can make the connection more smooth, and the overall structure will be more evenly stressed. This not only improves the appearance but also enhances the safety of use.

What are Countersunk Blind Rivets Used for?

Countersunk Blind Rivets are a type of connection fastener that can be installed on one side and has a smooth surface. They are widely used in structures with high requirements for appearance and streamlined design. Here are a few key application industries and scenarios:

1. Aerospace: Reducing Aerodynamic Resistance

- Typical Application: Skin of the fuselage, edge structure of the wings.

- Advantage: The countersunk design is flush with the surface of the aircraft body, effectively reducing air resistance.

- Result: Improves fuel efficiency, extends the service life of the aircraft.

The data shows that for every 1% reduction in aerodynamic drag, the flight range efficiency can be improved by approximately 0.5% (Boeing Technical White Paper).

2. Automobile Manufacturing: Anti-corrosion and Chassis Protection

- Typical Applications: Body shell, sill panel, chassis covering parts.

- Advantages: Anti-hooking, waterproof leakage, preventing local rusting.

- Result: Enhances the durability and safety of the entire vehicle.

Compared with ordinary rivets, countersunk blind rivets reduce the surface protrusion by 15% to 20%, thereby reducing the risk of scratches.

3. Ships and Offshore Structures: Smooth Surface to Prevent Water Flow Resistance

- Typical Applications: Deck jointing, hull skinning, boat body armor.

- Advantages: Smooth structure, avoiding increased resistance due to seawater turbulence.

- Result: Improved speed and enhanced structural anti-corrosion performance.

In the design of high-speed boats, the use of countersunk rivets can increase the cruising speed by approximately 3% to 5% (source: ABS Ship Structural Standards).

4. Electronic and Precision Equipment: Precision Shell Assembly

- Typical Applications: Laptop cases, electronic control panels, cabinets.

- Advantages: The outer shell is smooth, and the internal components are less likely to be disturbed.

- Outcome: Combines aesthetics with functionality, facilitating the design of compact structures.

The use of countersunk rivets in the electronic housing can increase the available installation area for internal components by more than 20%.

5. Furniture and Architectural Decoration: Beauty and Safety

- Typical Application: Metal doors and windows, display cabinets, cabinet structures.

- Advantages: Smooth installation surface, preventing scratches, enhancing decorative effect.

- Result: Improves product grade, meets high-end design requirements.

Self-tapping screws are widely used in modern minimalist designs, balancing both aesthetics and functionality.

Suggestions for Material Selection of Countersunk Blind Rivets

Choosing the appropriate rivet material directly affects the structural stability and service life. The following are selection suggestions based on actual working conditions:

Interior Assembly: Lightweight and Easy to Process

- Recommended Materials: Aluminum, Copper.

- Application Scenarios: Display cabinets, electrical equipment, furniture assembly.

- Advantages: Aluminum is lightweight and easy to process, making it suitable for mass assembly; Copper has excellent electrical conductivity and is suitable for electrical connections.

- Precautions: Aluminum is not resistant to corrosion and should not be used in humid or acidic environments.

The weight of aluminum rivets is only one third that of stainless steel ones, making them suitable for structures that are sensitive to weight.

Outdoor or Wet Environments: The Preferred Choice for Rust Prevention

- Recommended Materials: Stainless steel (304/316) or anti-corrosion coated carbon steel.

- Application Scenarios: Doors and windows, outdoor signs, vehicle exteriors.

- Advantages: Stainless steel has excellent corrosion resistance and won’t rust over a long period of use; coated rivets offer better cost-effectiveness and are suitable for medium to short-term projects.

- Precautions: Before installation, check the electrochemical compatibility of the substrate to avoid “galvanic corrosion”.

The Rivmate experimental data shows that the 316 stainless steel rivets can withstand corrosion for more than 1,000 hours in the salt spray test.

High-strength Load-bearing Structure: Select Structural Alloy Steel

- Recommended Material: Alloy steel structural type countersunk blind rivets.

- Application Scenarios: Mechanical frames, engineering vehicles, steel structure connections.

- Advantages: Possess higher shear strength and tensile strength, suitable for load-bearing parts.

- Precautions: Installation requires cooperation with a hydraulic riveting gun to ensure the locking force meets the design requirements.

The shear strength of the structural blind rivets can be more than three times that of ordinary aluminum rivets (as tested by Rivmate).

Installation and Design Considerations

The shear strength of the structural blind rivets can be more than three times that of ordinary aluminum rivets (as tested by Rivmate).

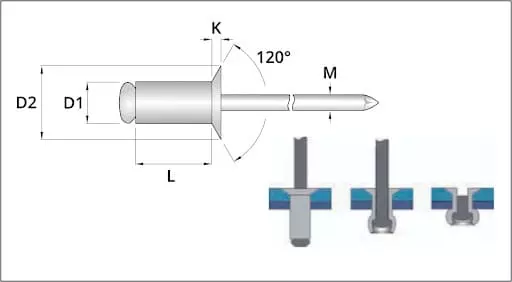

①. Hole Diameter and Blind Hole Depth Standards

Suggestion: The aperture should be 0.1 – 0.2mm larger than the diameter of the rivet rod to ensure a smooth insertion.

Drill hole depth: Ensure that the head of the rivet is precisely inserted and does not protrude or sink.

Risk: If the hole diameter is too small, it may cause the rivet to deform; if it is too large, it will not be able to effectively hold the object. Improperly sized countersunk holes may expose the bottom or affect the tightening force.

Reference standard: DIN ISO 7721 provides clear dimensional specifications for headless screw hole designs.

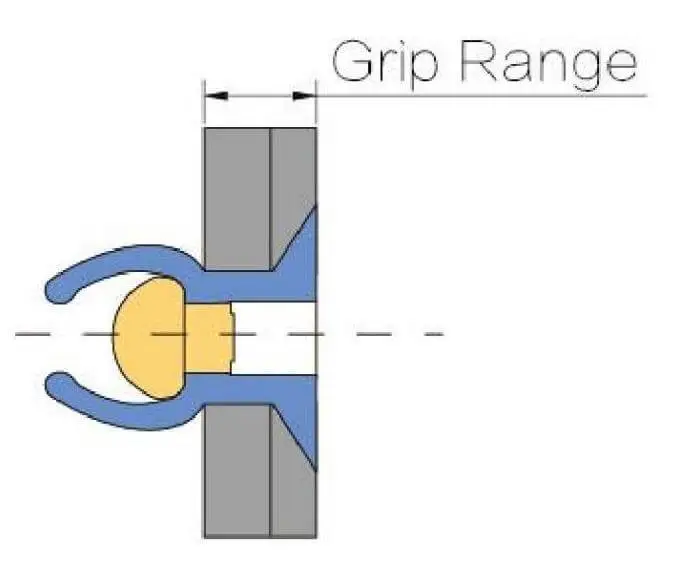

②. The grip range must be precisely matched

Definition: The grip range is the total thickness of the sheet material that the rivet can effectively grip.

Misconception: Exceeding the clamping range will result in “false tightness”, and it is prone to loosen over time.

Suggestion: Before designing, check the rivet specification table and choose values around the median for matching.

Rivmate data shows that for rivets that are installed beyond the clamping limit, their tensile strength decreases by approximately 30%.

③. Limitations of Blind Installation Process

Application: Suitable for structures with single-sided contact, such as closed cavities and box structures.

Challenge: It is impossible to visually confirm the quality of the rear molding, and this requires reliance on the precision of the tools.

Tool Recommendation: Rivmate suggests using pneumatic or hydraulic riveting guns, with a breakaway control system.

Recommended model: Rivmate RM-725 (equipped with automatic clamping and travel feedback functions, suitable for batch assembly).

④. Avoid stress concentration and deformation of the sheet material

Design Tips: Try to avoid the edges of thin plates and the areas near welds; when the plate thickness is less than 1mm, shims or reinforcing ribs should be added.

Pitch Arrangement: The spacing between rivets should be no less than 3 times the diameter of the rivets, and the edge distance should be no less than 2 times the diameter.

Objective: To reduce local stress concentration caused by thermal expansion and contraction or mechanical shock.

The CAE simulation of the structure indicates that proper layout can reduce the peak stress concentration by up to 40%.

Countersunk Blind Rivets' Advantages in Projects that Balance Aesthetics and Performance

Rivmate adopts precise molding technology to ensure a perfect fit between the countersunk head and the surface of the board. After installation, the surface is smooth without any protrusions, which will not affect the appearance and can also reduce the risk of scratches.

We offer a variety of anti-corrosion coatings and color options. Whether for marine environments, outdoor projects, or interior decoration projects, we can ensure both durability and visual appeal. The coatings have passed multiple salt spray tests, guaranteeing stable color and performance even after long-term use.

In a certain aviation part manufacturing project, Rivmate customized countersunk blind rivets for the client. By optimizing the angle of the rivet and the size of the countersink, the assembly quality was significantly improved. The client reported that the appearance consistency was enhanced by 20%, and at the same time, the rework rate due to uneven surfaces was reduced. This case demonstrates that high-quality rivets not only enhance structural strength but also improve the overall visual and brand image.

FAQ

Is the Countersunk Blind Rivet less strong than a regular rivet?

Not necessarily.

The strength mainly depends on the material and the type of structure, rather than the head shape. For instance, the tensile strength of the structural type stainless steel countersunk blind rivets can be exactly the same as, or even better than, that of the flat-head rivets of the same grade. However, if used for high-load connections, it is recommended to choose products with a locking core locking structure.

When designing, priority should be given to ensuring the “shear/stretch strength” matches the working conditions, rather than merely relying on the shape to determine the performance.

Can this type of rivet be disassembled repeatedly?

No.

Blind rivets are one-time fasteners. Once the core breaks, they cannot be restored. If disassembly is required, the original rivet must be destroyed by drilling. If the project requires a detachable structure, it is recommended to use screws, pull rivets, or detachable blind rivets. After disassembly, if reinstallation is needed, a new rivet must be replaced and the diameter of the hole checked to ensure it has not expanded.

Is it necessary to make a hole for installation?

Yes, if you want the surfaces to be flush with each other, pre-drilled holes must be made beforehand.

The angle of the blind hole needs to match the shape of the rivet head (commonly 120° or 90°). Direct installation without a blind hole will cause the rivet head to protrude above the surface of the board, which not only affects the appearance but may also cause contact interference. It is recommended to use a dedicated blind hole tool to ensure that the hole diameter and angle are consistent, avoiding the “floating head” problem.

Can it be used on plastic or composite materials?

Yes, but be aware of the risks of deformation and cracking. Plastics/composites have lower rigidity and are prone to damage due to excessive expansion force from the core pulling. It is recommended to choose a specialized model with less clamping force, or install a metal gasket at the hole opening to distribute the stress.

Some Rivmate models are suitable for plastic plate connections, featuring a low expansion force design and a large contact area with the large head plate.

Conclusion and Procurement Suggestions

The head-down blind rivets, with their smooth shape, easy installation and reliable structure, are widely used in various fields such as aerospace, automobiles, electronics, and construction. They not only enhance the structural strength but also meet the design requirements that prioritize both aesthetics and safety.

Rivmate focuses on precise fastening solutions and offers:

- Various material options (aluminum, stainless steel, alloy steel, etc.);

- Multiple head angle and corrosion-resistant coating options;

- Supports customized clamping range and special tool matching solutions.

Whether it is small-scale development and trial production, or large-scale automated assembly, Rivmate can provide you with stable performance and high cost-effectiveness in terms of fastening selection support

Please feel free to contact the Rivmate engineering team to obtain samples or get selection advice, to help you create high-standard industrial connection solutions.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met