What Are Sealed Rivet ?

Table of Contents

Although common blind rivets are easy to install, they often fail structurally due to water seepage, corrosion or loosening in damp, outdoor or salt spray environments. At this point, sealed rivets become the most ideal alternative. It achieves a completely waterproof, dustproof and gas-permeable connection effect by forming a closed structure at the tail. Suitable for application scenarios that require long-term sealing and stability. This article will provide you with a comprehensive analysis of the true value of sealed blind rivet.

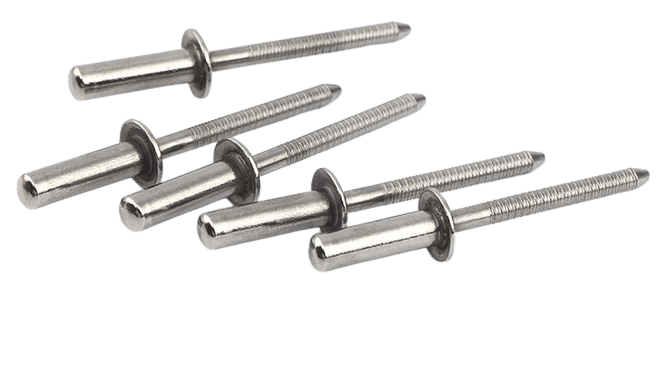

In the field of industrial fastening, Sealed Rivet is a high-performance Blind Rivet specifically designed for water resistance, dust resistance and gas leakage prevention. Unlike ordinary open rivets, the tail of Sealed Rivet is a closed-end Design. During the riveting process, the mandrel is permanently locked inside the rivet, forming a Closed cavity. This design effectively prevents liquids, air or grease from seeping through the connection holes, ensuring the sealing and protective performance of the assembly structure.

Its structure is usually composed of three parts:

- Body – The tail end is closed, providing a sealing barrier;

- Mandrel – It generates radial expansion during riveting, forming a clamping force;

- Break Point – After riveting is completed, the mandrel breaks and remains inside the body, enhancing the protective effect.

According to the international standards ASTM F1470 and ISO 15983, qualified Sealed Rivet must pass strict tests in terms of sealing performance, corrosion resistance and shear strength. This type of rivet is widely used in ships, automobiles, photovoltaic, electronic enclosures and outdoor equipment, etc., where high sealing performance is required.

Sealed Rivet vs Open-End Rivet: What’s the Real Difference?

In industrial fastening applications, Sealed Rivet and Open-End Rivet are the two most often confused types. They are structurally similar, but there are significant differences in performance, protection capabilities and application scenarios.

| Comparison Item | Sealed Rivet (Closed-End Rivet) | Open-End Rivet |

|---|---|---|

| Structure | The tail end is completely closed, and the mandrel is locked inside forming an airtight cavity. | The tail end is open, and part of the mandrel remains exposed after being pulled. |

| Sealing Performance | Excellent watertight, dustproof, and airtight sealing capability. | No sealing; prone to leakage or corrosion points. |

| Corrosion Resistance | Excellent — available in stainless steel, anodized aluminum, or coated versions. | Moderate — suitable only for dry, indoor environments. |

| Cost | Slightly higher than standard rivets, but offers longer service life. | Low cost, ideal for non-critical connections. |

| Typical Applications | Marine structures, automotive chassis, solar brackets, outdoor equipment. | Sheet metal, appliances, and general machinery assembly. |

Sealed Rivet is an upgraded blind rivet designed for the requirements of protection and sealing. Compared with open rivets, it performs better in terms of water resistance, corrosion resistance and structural stability, and is an indispensable fastener in applications with high sealing requirements such as Marine environments, automotive manufacturing and electronic equipment casings.

Key Advantages of Sealed Rivets

Unlike traditional open rivets, Sealed Rivet not only offers mechanical connections but also maintains airtightness and water resistance in extreme environments. The following are the core advantages that have been widely adopted in practical applications:

- Watertight and Airtight

The Sealed Rivet has a completely sealed tail end, which can effectively prevent moisture, dust and gas from seeping in. It is suitable for occasions exposed to rain, dampness, immersion and high sealing requirements, such as ship hulls, vehicle chassis and electrical enclosures.

- Corrosion Resistance

The rivets and mandrels are made of stainless steel or anodized aluminum alloy, featuring excellent oxidation resistance and salt spray resistance. It can remain stable and rust-free for a long time even in the ocean or high-humidity environments.

- Consistent Performance

The mandrel is permanently retained in the rivet after riveting, creating a structural reinforcement effect. It has enhanced the overall shear and tensile strength, ensuring the stability of long-term connections.

- Maintenance-Free

After riveting is completed, there is no need to tighten or seal again, making it suitable for long-term unattended equipment. It has a long service life and low maintenance costs in the later stage.

- Ease of Installation

No special equipment is required. Just a standard blind riveting gun is needed for quick installation. Suitable for mass production, on-site construction and maintenance operations.

Applications of Sealed Rivets

Sealed Rivet not only offer strength and stability, but also ensure the structure’s waterproof, dustproof and anti-corrosion performance. It is especially suitable for application scenarios under long-term outdoor or humid conditions.

The following are the four typical application areas of Sealed Rivet:

Marine & Boats

Closed rivets can prevent seawater and moisture from penetrating into the interior of the aluminum alloy hull, effectively avoiding electrochemical corrosion and structural fatigue problems. It is widely used in parts such as bulkheads, deck joints, and side guard plates.

Automotive & Truck Body Assembly

Sealed Rivet is an ideal choice for sealing the car chassis, doors and waterproofing the tailgate. It can prevent dust and moisture from entering and enhance the overall protection level of the vehicle (commonly used in IP grade design).

Outdoor Equipment/Solar Brackets

Long-term exposure to high temperatures, humidity, ultraviolet rays and sandstorms can maintain the waterproof and anti-corrosion properties of closed rivets, making them the preferred fasteners for solar installation structures.

Enclosures & Panels

For control boxes, antenna covers or electrical enclosures that require air tightness and weather resistance, Sealed Rivet can ensure that the seams are sealed, preventing electrical short circuits and moisture intrusion.

Material and Specification Guide for Sealed Rivets

Different metal materials not only affect the mechanical strength of rivets, but also determine their anti-corrosion performance, service life and compatibility with the base material. Correct material matching can effectively prevent electrochemical corrosion, enhance sealing reliability, and extend the overall structural lifespan. The following are common materials for closed rivets and their application suggestions:

| Material | Features | Recommended Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, easy to install; no galvanic reaction with aluminum substrates. | General sheet metal, outdoor equipment, solar mounting systems. |

| Stainless Steel (304 / 316) | Excellent corrosion resistance and mechanical strength; withstands high humidity and salt spray. | Marine structures, automotive chassis, coastal constructions, food processing equipment. |

| Steel with Zinc Coating | Low cost and high strength, but limited corrosion resistance. | Indoor machinery, non-humid or non-salt environments. |

| Copper / Brass | Excellent conductivity and decorative finish; ideal for electrical or precision components. | Electrical grounding, instrument housings, electronic device assemblies. |

When choosing Sealed Rivet, please be sure to evaluate:

- Base Material Compatibility : Avoid electrochemical reactions between different metals (for example, aluminum + stainless steel may cause pitting corrosion).

- Environmental Condition : If exposed to high humidity, salt spray or outdoors for a long time, 316 stainless steel closed rivets should be preferred.

How to Install Sealed Rivets?

The correct installation method is the key to ensuring that the Sealed Rivet achieves the ideal waterproof and anti-corrosion performance. Even if high-quality rivets are selected, improper installation techniques may still lead to seal failure or structural loosening. The following is the standardized installation process summarized by the Rivmate engineering and technical team:

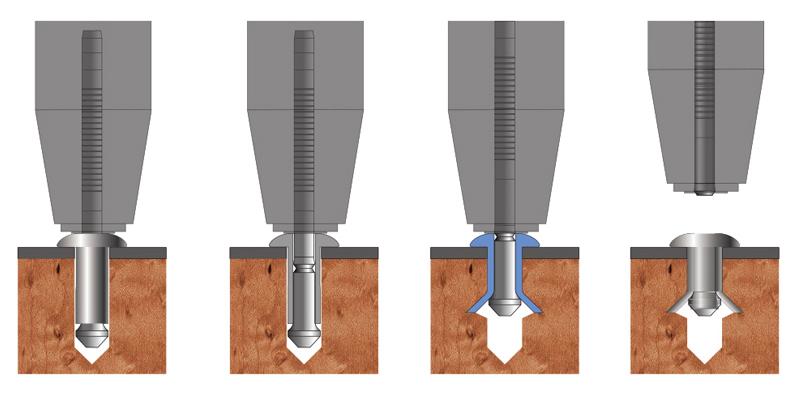

Step1: Pre-Drilling

Pre-drill installation holes on the workpiece using drill bits of appropriate specifications. The hole diameter should be 0.1 to 0.2 mm larger than the rivet diameter to ensure that the rivets can be inserted smoothly without loosening. Meanwhile, the hole wall must be clean and free of burrs to prevent affecting the bonding of the sealing surface.

Step2: Insert the Rivet

Insert the Sealed Rivet into the hole and ensure that the Flange Head is closely attached to the surface of the workpiece. This step determines the integrity of the seal. If there is any tilt or foreign matter on the surface, it should be repositioned.

Step3: Set with a Rivet Gun

Use a standard blind riveting gun (manual, pneumatic or electric) to pull the mandrel until it breaks and forms a complete lock. At the moment of fracture, the tail cavity is completely sealed, forming an airtight and waterproof structure.

Step4: Inspect the Joint

Observe whether the cap part is flat and there is no leakage gap at the tail end. When necessary, air tightness or water tightness tests (such as bubble or spray methods) can be conducted to ensure there is no leakage at the connection points.

FAQ

1. What are sealed rivets used for?

Sealed Rivets are mainly used in structures that require water resistance, dust resistance or air tightness. Typical applications include: ships, automotive chassis, outdoor equipment, photovoltaic brackets and electronic enclosures, etc. It can effectively prevent liquids or gases from seeping into the connection points, ensuring the sealing integrity of the system.

2. Are sealed rivets waterproof?

Yes. The tail end of Sealed Rivet is of a closed structure. After installation, it can form a 100% waterproof seal, which can maintain long-term stability in rainy, humid or underwater environments without the need for additional sealant.

Absolutely fine. Closed aluminum rivets or stainless steel rivets are highly suitable for aluminum ship applications. It is recommended to choose Rivmate Marine Series Sealed Rivet, combined with 316 stainless steel core shaft and anodized aluminum body, which can effectively prevent electrochemical corrosion and salt spray erosion.

Closed-End rivets have a completely sealed tail, which can prevent the penetration of liquids or gases. The open-end rivets have an Open tail, and the mandrel is exposed when broken, thus lacking sealing capability. The strengths of the two are similar, but the Sealed Rivet is more suitable for protective applications.

5. How strong are sealed rivets compared to standard rivets?

The strength of Sealed Rivet is comparable to that of standard rivets, but because the mandrel remains in the rivet, it usually offers higher shear and tensile strength (about 10-15% higher). Meanwhile, its internal locking structure enhances vibration resistance and sealing stability.

Protect Every Connection with Rivmate Sealed Rivets

Unlike traditional open rivets, the tail closure design of Sealed Rivet makes it significantly superior in terms of water resistance, dust resistance and corrosion resistance. Verified by ASTM B117 salt spray test and ISO 15983 sealing standard, the Rivmate closed series rivets can maintain no corrosion performance for more than 500 hours in extreme hot and humid or high-salt environments.

If your project has strict requirements for sealing, anti-corrosion or structural durability, choosing Rivmate Sealed Rivet means choosing a connection solution with longer lifespan and higher reliability.

👉 Protect Every Connection with Rivmate Sealed Rivets

Contact us immediately to obtain Marine and industrial-grade waterproof rivet solutions.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met