What Is Metal Riveting?

Table of Contents

In the field of industrial manufacturing, metal riveting is a time-honored yet highly reliable mechanical connection technology. It is widely used in key areas such as automotive manufacturing, sheet metal processing, and equipment assembly. Compared to welding or bolt connections, riveting offers advantages such as stable structure, no need for threads, and less susceptibility to heat. It is suitable for long-term connection requirements in different materials, non-detachable, or vibration environments.

Many manufacturing workers often search for “what is metal riveting” through search engines at the beginning of a project to quickly understand the basic structure, working method, and performance of riveting in practical applications. This article will systematically explain the definition, structure, and working principle of metal riveting, and provide practical design and assembly suggestions around these common questions.

Metal Riveting – Definition and Basic Principles

a. Definition

Metal riveting is a process that permanently connects two or more pieces of metal through mechanical means using rivets. The rivets are inserted into the connection components through pre-drilled holes, and then the tail end of the rivet undergoes plastic deformation to form a “rivet head”, creating a clamping force between the parts, thus achieving a secure connection.

b. Working Principle

During the riveting process, the rivet passes through the aligned holes of the workpiece and forms a second rivet head at the stressed end (or breaks to form a clamping structure). This process does not rely on threads or melting and has good structural strength and shear strength.

c. Riveting vs. Other Joining Methods

| Joining Method | Advantages | Limitations |

|---|---|---|

| Riveting | Suitable for lightweight structures, requires no electricity, allows one-sided installation; no heat treatment needed, good fatigue resistance | Difficult to disassemble, poor reusability |

| Welding | High joint strength, excellent airtightness | Requires heat source, heat-affected zones, risk of structural deformation |

| Bolted Connection | Removable and easy to maintain | Requires regular tightening, relatively poor vibration resistance |

It is widely applied in industries such as aviation, rail transportation, construction and sheet metal processing, and is particularly suitable for structural scenarios that require lightweight and high strength while minimizing heat influence.

Common Types of Metal Rivets and Structural Classifications

Structural Features: Composed of the cap shell (outer cylinder) and the core pin. During installation, it only requires a single operation on one side. After the core pin is pulled out, it forms a back rivet.

Advantages: One-sided installation, simple operation, high efficiency, suitable for thin plate connections.

Disadvantage: The strength is average and the load-bearing capacity is limited. It is not suitable for high-load situations.

Installation Tools: Manual or pneumatic riveting gun.

Applicable scenarios: Electronic enclosures, sheet metal parts, household appliances, and lightweight structural assemblies.

Structural Feature: The core pin is tightly locked with the housing. After being pulled apart, it has higher shear and tensile strength, making it suitable for high structural load requirements.

Advantages: High strength, anti-loosening, anti-vibration. Some models feature a lock mechanism design.

Disadvantages: High cost, requires more specialized installation tools.

Applicable scenarios: Automotive body, truck trailers, heavy machinery structures, steel structure connections.

Installation Tools: Heavy-duty pneumatic riveting gun or electric riveting equipment.

3. Closed-End Rivet

Structural Feature: The tail is sealed, which prevents leakage of liquids and gases; the core pin remains inside the sealed cavity.

Advantages: Excellent sealing performance, suitable for applications with high sealing requirements.

Disadvantage: The shear strength is slightly lower than that of structural rivets.

Applicable scenarios: Electrical cabinets, sealed containers, air conditioning housings, waterproof joints.

Installation Tools: Ordinary riveting gun or pneumatic sealing riveting tool.

4. Peel Pattern / Snap Collar and Grooved Rivet

Structural Characteristics

- Flowering Type: The tail of the rivet expands into four petals when tightened, providing a large supporting area.

- Groove Type: The rivet body is equipped with grooves, suitable for soft materials (such as plastic, wood).

Advantages: Suitable for fragile and soft materials. It can disperse stress without damaging the substrate.

Disadvantage: The structural strength is relatively low and it is mainly used for non-structural connections.

Applicable scenarios: Toy assembly, plastic shells, woodworking products, small electronic devices.

Installation tool: Ordinary riveting gun.

Advantages and Limitations of Metal Riveting

Analysis of Advantages

- No need for heat source

Bolted connections do not require high temperatures and are suitable for materials that are prone to deformation or alteration, such as aluminum alloys and thermoplastic composites. Industrial data shows that bolted connections can reduce energy consumption by approximately 20-30% compared to the arc welding process. - High consistency

The riveting process has a high degree of standardization, resulting in stable product quality. It is suitable for mass production and automated operations. - Strong anti-vibration performance

After plastic deformation, the rivets form a fastening structure, which has excellent vibration resistance and anti-loosening capabilities. - Single-Sided Construction

Through structures such as core-pulling rivets, it is possible to install from only one side of the structure, which is suitable for situations with limited space. - Lightweight

Compared with bolt connections, the rivet assembly is lighter and aligns with the trend of lightweight design, making it particularly suitable for the transportation industry. - Installation speed

Each riveting cycle only takes 1-3 seconds (using manual or pneumatic tools), significantly longer than the 6-8 seconds required for torque-controlled bolts. This can increase the production line efficiency by approximately 15-20%.

Analysis of Limitations

- Irreversible disassembly Bolted connections are a permanent connection method. Disassembly requires damaging the components, which is not conducive to maintenance or repeated assembly.

- Limited connection strength The shear strength of conventional blind rivets is approximately 200 – 300 N/mm², which is significantly lower than the 800 N/mm² of grade 8.8 bolts. Therefore, they are not recommended for use in structures that need to withstand large axial loads.

- High requirements for hole positions The riveting effect depends on the precise positioning and matching of the holes, and the construction process requires strict control of tolerances.

- Material Compatibility Issues Different metal combinations (such as aluminum + stainless steel) will generate a 0.5 – 0.8 V potential difference in a humid environment. According to the Galvanic Series data, the corrosion rate can accelerate by several times within one year.

- Lack of Adjustability After the riveting is completed, the structure cannot be adjusted, and it lacks flexibility compared to bolt connections.

Overview of Metal Riveting Application Scenarios

In the aerospace field, metal riveting is mainly used for assembling the fuselage skins, wings, cockpits and other structures of aircraft. Solid rivets or high-strength structural type coreless rivets are adopted, and the materials are mostly aluminum alloys or titanium alloys. Since the entire aircraft requires tens of thousands of riveting connections, extremely high strength, fatigue life and lightweighting are required.

In the automotive manufacturing industry, riveting is commonly used for connecting car doors, chassis, seat brackets and energy absorption structures. To meet the requirements of impact resistance, anti-loosening and corrosion resistance, structural type ejector rivets (such as MGR or Monobolt) are usually selected. They are combined with welding and screwing methods to form a mixed connection, enhancing the overall structural reliability.

In the building assembly scenario, metal riveting is widely used in curtain wall systems, steel structure splicing, and bridge installation. Closed-type or high-strength structural rivets are selected to meet the requirements of waterproofing, wind load resistance, and outdoor durability.

In the manufacturing of sheet metal and equipment shells, such as electrical control cabinets, chassis, and automation equipment frames, etc. Riveting is an efficient, aesthetically pleasing, and corrosion-resistant connection method. Typically, open-type or closed-type blind rivets are selected, which are suitable for thin plate structures.

Design and Engineering Guidelines for Metal Riveting

1. Design of Aperture, Edge Distance and Center Distance

Recommended Design Value (D = Bolt Diameter):

- Diameter Ø: Generally, it is recommended to be slightly larger than the diameter of the rivet by 0.1 – 0.2 mm to ensure smooth insertion and stable clamping.

- Pitch ≥ 3D: Prevents interference between materials and facilitates uniform load distribution.

- Edge ≥ 2D: Avoids material edge tearing during riveting. Example: If 4.8 mm rivets are selected, it is recommended that the center distance be ≥ 14.4 mm, the edge distance be ≥ 9.6 mm, and the hole diameter be approximately 4.9 – 5.0 mm. >

NOTES

- Irregular center distance will cause concentrated load, reducing fatigue life.

- Insufficient edge distance is prone to cause tearing and sliding risks, especially under tensile load.

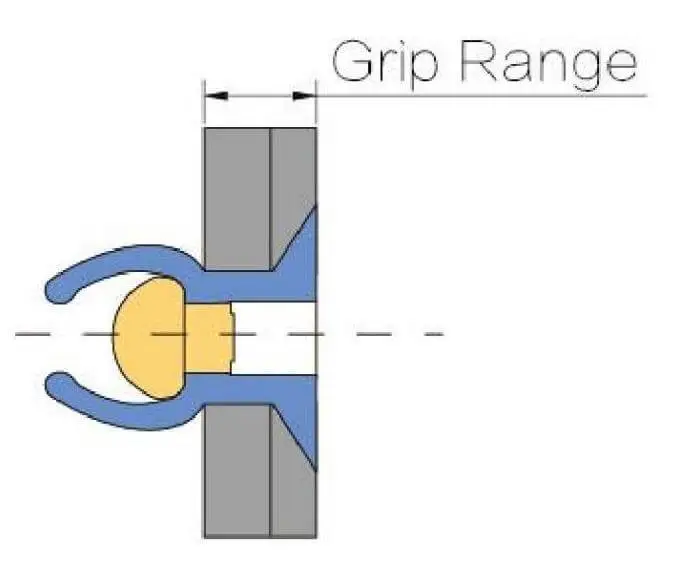

2. Grip Range and Nail Type Selection Process

Definition: The grip range refers to the total thickness of the connected materials (including the gap) being within the clamping thickness range permitted by the design of the rivet.

Selection Process:

- Confirm the total thickness of the materials (for example: 1.2 mm + 2.0 mm = 3.2 mm)

- Refer to the rivet specification table, select a gripping range that covers this thickness (for example 2.5 – 4.0 mm)

- Ensure that the outer diameter of the pull pin head matches the hole diameter, avoiding gaps or being too tight

- Choose the appropriate head type (flat head, countersunk head, large flat head), based on the assembly position, appearance or requirements for blind holes

Note: Selecting the wrong gripping range can result in poor formation of the riveting joint. In severe cases, it may lead to failure or cause the appearance of “false riveting” phenomenon.

3. Material Matching and Corrosion Protection Design

Material Matching Principle: Preferentially select rivets with an electrochemical potential similar to that of the base material to avoid electrochemical corrosion.

| Rivet Material | Recommended Base Materials | Characteristics |

|---|---|---|

| Aluminum Alloy | Aluminum, plastics, composites | Lightweight, rust-resistant, moderate strength |

| Stainless Steel | Stainless steel, steel | High strength, corrosion-resistant, may cause galvanic corrosion with aluminum |

| Copper | Copper, brass structures | Excellent conductivity, corrosion-resistant |

| Steel (Zinc-coated/Painted) | Steel structures | High strength, requires anti-rust treatment |

Anti-corrosion Measures Suggestions:

- Anode protection coating (such as anodic aluminum oxide, zinc coating)

- Isolation gasket or anti-corrosion rubber ring, preventing direct contact between metals

- Regular application of anti-rust agent or sealant to the bolt connection area

- Sealed bolts can prevent water vapor from entering the connection holes, suitable for humid environments

Common Riveting Implementation Errors and Preventive Measures

1. Incorrect selection of nail type or size

Problem Description:

- The rivets are too short: They cannot be securely clamped, resulting in false riveting and prone to falling off.

- The rivets are too long: The core pulling process is insufficient, leading to failure of the riveting or deformation of the head.

- Incorrect rivet type selection: For structural requirements, ordinary core-pulling rivets are used, resulting in insufficient strength.

Preventive Measures

- Use the “grip range chart” to confirm the model

- For high-load or critical structures, preferentially select “structural rivets” and combine with shear/extension strength calculations

- Regularly train the selection personnel to master the logic of material and function matching

Problem Description:

- Too large hole: The rivets are loose and the clamping force is insufficient.

- Too small hole: The rivets are difficult to insert and may cause deformation or damage to the coating.

- Hole position deviation: It affects alignment and the quality of forming.

Preventive Measures

- Use standard diameter drill bits (recommended gap 0.1 – 0.2 mm)

- Introduce positioning fixtures or laser marking to ensure the accuracy of the hole positions

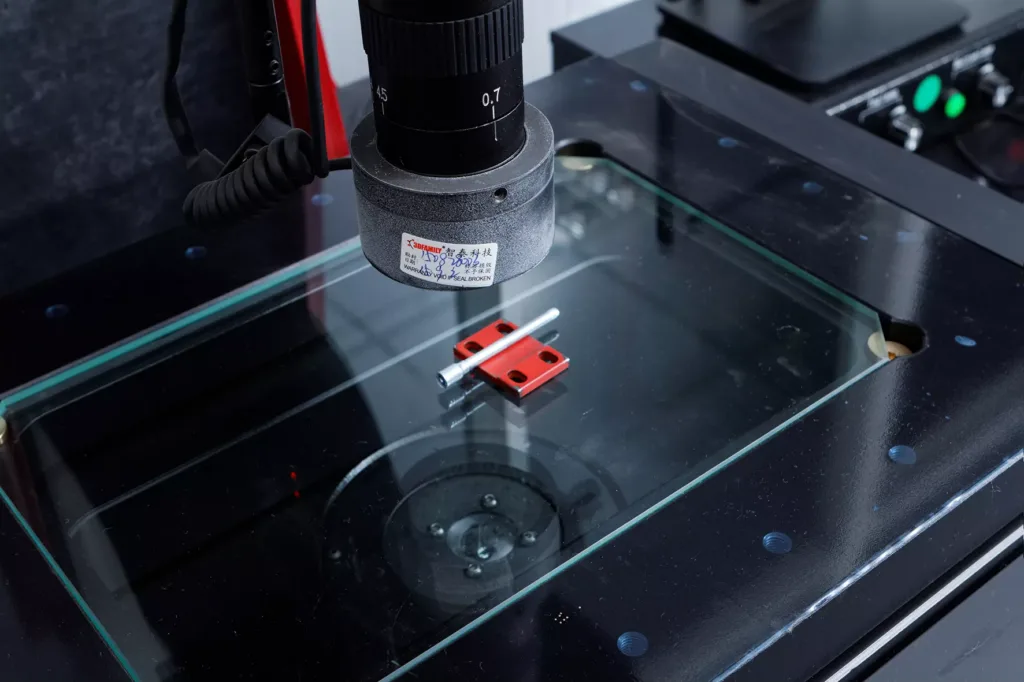

- For automated production, it is recommended to configure online visual inspection or hole position deviation alarm mechanisms

3. Installation with Angle Deviation

Problem Description:

- The rivets entered at an angle, resulting in an asymmetrical deformation on the back.

- Poor shaping led to uneven distribution of clamping force and loosening of the connection.

Preventive Measures

- The tool is equipped with a vertical guide sleeve to ensure consistent force application direction.

- The operation platform design should maintain horizontal rigidity and stability.

- Educate the operators to follow the vertical pressure application process and conduct regular rechecks.

4. The core extraction was incomplete or the core pin did not break

Problem Description:

- The core pins remain partially connected and the riveting is not secure.

- The core pins are misaligned or have fallen off, which affects the structural integrity.

Preventive Measures

- Use an air pressure-stabilized riveting gun to avoid insufficient core pin pulling force.

- Regularly maintain the tool’s gripper to prevent slippage.

- It is recommended to set up a visual confirmation station or sensor feedback to ensure the core pin breaking action is completed.

5. Inappropriate selection of materials

Problem Description:

- Electrochemical corrosion: The combination of aluminum and stainless steel undergoes accelerated corrosion in a humid environment.

- Incompatibility of material strength: The strength of the rivets is higher than that of the base material, which may cause damage to the base material.

Preventive Measures

- Establish a material compatibility comparison table to assist in selection

- In humid and hot environments, it is recommended to use closed-type rivets + anti-corrosion coating

- For soft materials (such as plastics, composite panels), choose flower-shaped or slot-type rivets

Quality Control and Inspection Recommendations for Metal Riveting

Tensile/Shear Test

Regularly conduct stretch and shear strength tests to verify whether the riveted structure can meet the design load requirements. It is recommended to sample test different batches and different workstations, using standard test fixtures (such as ASTM F606 or ISO 14589 specifications), and set warning thresholds for abnormal values.

Fatigue Testing

For critical load-bearing structures, especially in cases of vibration or dynamic loads, cyclic fatigue tests should be conducted to simulate the reliability of the riveted joints under long-term conditions. It is recommended to combine the results of FMEA analysis and prioritize the verification of high-risk areas.

Visual & Dimensional Checklist

Establish a standardized inspection checklist to visually and dimensionally confirm the integrity of the rivet head shape, core pin fracture, hole diameter fit, and rivet verticality. Using a graphical template can enhance the identification efficiency of front-line employees and support QA for quick review.

Assembly SOP and Process Control Recommendations

Establish clear assembly standard operation procedures (SOP), covering:

- Process for confirming and verifying the model of rivets

- Parameter verification of tool settings (force/extension)

- Control of riveting sequence and operation cycle

- Countermeasures for defects and rework procedures

It is suggested to integrate the SOP with the “digital tool feedback system” (such as workstation scanning for confirmation and automatic recording of torque/position), to achieve full-process traceability.

Conclusion – Ensuring Reliable Riveted Connections

Metal riveting is a highly efficient, lightweight and standardized connection method. It plays an irreplaceable role in various industries such as aviation and automobiles. Its key value lies in its ability to combine structural strength, vibration resistance performance and assembly efficiency. It is suitable for scenarios where single-side operation is possible and heat influence is limited.

It is suggested that enterprises establish a systematic riveting knowledge base and standardized design process. This should cover selection principles, mechanical compatibility, material compatibility and quality control. At the same time, combine simulation modeling, fatigue testing and on-site verification. This can continuously enhance structural reliability and promote the transition from process stability to engineering optimality.

Conclusion – Ensuring Reliable Riveted Connections

Metal riveting is a highly efficient, lightweight and standardized connection method. It plays an irreplaceable role in various industries such as aviation and automobiles. Its key value lies in its ability to combine structural strength, vibration resistance performance and assembly efficiency. It is suitable for scenarios where single-side operation is possible and heat influence is limited.

It is suggested that enterprises establish a systematic riveting knowledge base and standardized design process. This should cover selection principles, mechanical compatibility, material compatibility and quality control. At the same time, combine simulation modeling, fatigue testing and on-site verification. This can continuously enhance structural reliability and promote the transition from process stability to engineering optimality.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met