What is Self Piercing Rivet ?

Table of Contents

Self Piercing Rivet can complete high-strength mechanical locking in one stamping without pre-drilling, achieving efficient connection between various materials such as aluminum, steel, and stainless steel. This paper will comprehensively analyze the working mechanism and engineering value of Self Piercing Rivet. Help you understand this key fastening technology that is reshaping modern manufacturing processes.

What is Self Piercing Rivet ?

Self piercing rivet (SPR rivet) is a cold joining process. Which two or even more layers of sheets of different materials are joined by penetrating them with rivets. The technology’s maximum capacity to date allows for the joining of aluminum plates with a cumulative thickness of 12 mm or steel plates with a thickness of 6 mm.

As one of the alternatives to spot welding, the biggest difference with SPR rivet is that it does not transfer heat to the material. As a result, there is no unnecessary damage to the finished product. the fastening point is more fatigue resistant and stronger. and it is kinder to the intermediate layer of material without causing excessive deformation.

Self-piercing rivets join a wide range of materials including high strength steel, galvanized steel, aluminum, plastics and composites. It is capable of joining different materials together and can also join materials that have been coated with various surface coatings without affecting the joining effect. For example, materials that have been lubricated, painted, coated or plated. SPR rivet can also be used to join materials that contain sealants, adhesives or insulating materials.

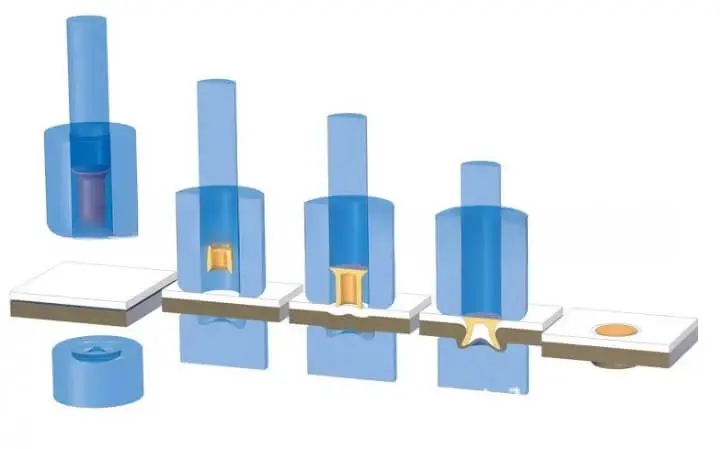

SPR Rivet works by applying the required pressure and force to penetrate and deform the material. The steps of SPR Rivet to produce a tightening effect are in order:

- By applying a certain amount of pressure, the rivet head begins to penetrate the first layer of material.

- As the rivet head continues to penetrate, it enters the second layer of material. During this process, the raised head of the rivet creates pressure that clamps the first and second layers of material together.

- When the head of the rivet completely penetrates and enters the second layer of material. the rod portion inside the body of the rivet is extruded and deformed. This process creates a diffuse shape that fills the gaps between the materials and creates a strong joint.

- Once the rod portion of the SPR rivet is fully extruded and deformed, it locks into the connected material. This type of connection provides a high level of strength and stability, allowing the connected materials to stay together.

How to Install Self Piercing Rivet?

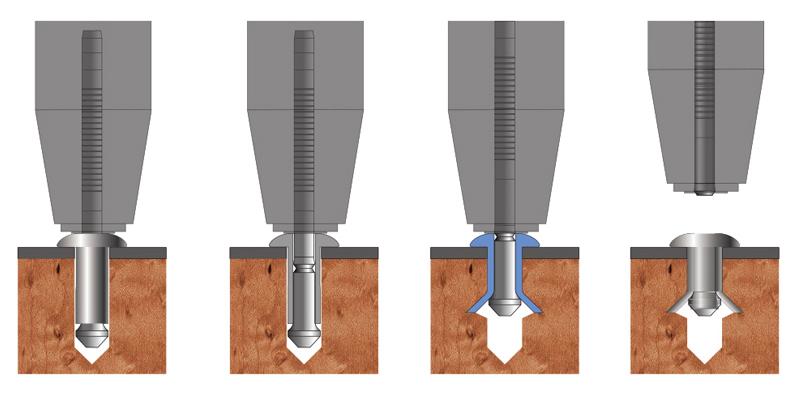

The SPR Rivet Riveting can be divided into four stages of the riveting process:

Clamping phase

The crimper presses down the sheet to be riveted. At the same time, the self piercing rivets are also pre-pressing the sheet vertically downwards under the drive of the punch.

Punching stage

The punch moves downward and pushes the self piercing rivet to force it to pierce the upper sheet. And at the same time, the self-piercing rivets also drive the lower sheet to deform plastically into the mold.

Expansion stage

As the riveting process proceeds, the self-piercing rivets legs gradually open and the lower sheet undergoes plastic deformation, gradually filling into the mold. Under the joint action of the convex mold and the cam, the self piercing rivet leg expands to the periphery and is embedded in the lower sheet, forming a mechanical interlocking structure between the self piercing rivets and the sheet.

Punch riveting completion

When the punch will self-piercing rivets downward pressure, until the spr rivet head and the upper surface of the upper piece of close contact and flush, can be considered riveting completed. At this time, the pressure edge will release the pressure edge force, the punch to restore the initial work, the end of the stamping riveting.

| Material | Features | Recommended Applications |

|---|---|---|

| Carbon Steel | High shear and tensile strength, cost-effective, suitable for mass production. | Ideal for steel frames, chassis, and structural beams requiring high strength. |

| Aluminum Alloy | Lightweight, corrosion-resistant, compatible with aluminum substrates to prevent galvanic corrosion. | Used in aluminum structures, automotive body panels, and appliance housings. |

| Stainless Steel (304/316) | Excellent corrosion and fatigue resistance; performs well in high-humidity or salt-spray environments. | Marine engineering, railway vehicles, coastal equipment, and new energy battery structures. |

| Coated Steel (Zn/Ni) | Zinc or nickel coating enhances corrosion resistance and provides versatility. | Automotive body assemblies, machinery housings, and general industrial equipment. |

a. Automotive Industry

In automotive manufacturing, lightweighting and structural safety are two key goals. Traditional spot welding cannot effectively combine aluminum alloy and high-strength steel, while SPR technology can achieve such connection of different materials without a heat source and without changing the metal structure.

- Typical parts: Side panels of the vehicle body, inner door panels, battery pack casings, and chassis connection components.

- Technical advantages: No pre-drilling is required. Clamping and locking are completed in a single punching and riveting operation. It does not cause welding thermal deformation and can be used on coated or anodized surfaces. 30% longer fatigue life than spot welding.

Railway Systems

Self-piercing rivets (SPR) can effectively connect aluminum profiles with stainless steel components, avoiding the problem of heat-affected zones caused by welding. SPR can withstand continuous vibration and periodic loads, making it suitable for high-speed train and metro car body structures. The Rivmate SPR system complies with EN 15085-3 and VDA 239-100 standards and has been successfully applied in various railway frame and door structures.

Aerospace Manufacturing

In aviation manufacturing, SPR technology is widely used for the mixed bonding of composite materials and aluminum/titanium alloys. Typical applications include fuselage skins, seat frames and cargo door support structures. Rivmate test data shows that the tensile strength of 6.3mm SPR can reach 10-12kN, which is 40% higher than that of traditional rivets.

Building & Facades

The requirements for the connecting components of the building curtain wall system are extremely high. They not only need to be waterproof and resistant to wind pressure, but also have a smooth and beautiful appearance. SPR can complete the connection of high-strength aluminum plates without weld seams or exposed nuts, ensuring the long-term stability of the curtain wall system.

Appliances & Electronics

In the assembly of household appliances and electronic equipment, SPR technology is widely used in the connection of sheet metal casings and frame structures due to its advantages of high efficiency, low noise and no sparks. It does not require pre-drilling or thread processing and is suitable for automated production lines.

| Comparison Item | Self Piercing Rivet (SPR) | Spot Welding | Blind Rivet |

|---|---|---|---|

| Need for Pre-drilling | No, pierces and fastens in one step | No, joins materials through heat fusion | Yes, requires pre-drilled holes for rivet insertion |

| Heat Effect | Cold process, no heat input or material distortion | High heat input, potential for deformation | No heat input |

| Material Compatibility | Can join dissimilar materials (Aluminum + Steel, Aluminum + Composites) | Limited to similar metals (usually steel) | Possible, but limited strength |

| Shear Strength | High (up to 8–12 kN) | Moderate (depends on thickness and material) | Moderate (around 4–6 kN) |

| Cost | Medium to high (higher equipment cost, moderate per joint) | Medium (requires welding equipment and power) | Low (ideal for light-duty assemblies) |

| Automation Compatibility | Excellent, easily integrated into robotic systems | Good | Limited, typically manual positioning required |

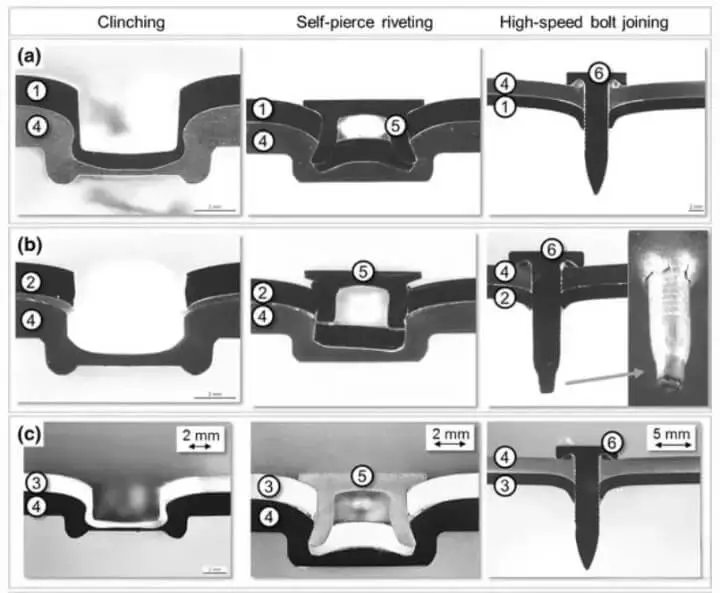

Different process methods

SPR achieves high-strength locking through mechanical punching and riveting, without the need for heat sources or pre-drilling. Welding, on the other hand, relies on melting metals at high temperatures, which can easily lead to material deformation and a decline in fatigue performance. Blind rivets are more suitable for single-sided operable and non-structural connections.

Obvious advantages in material compatibility

SPR is currently the only cold working technology that can directly connect aluminum alloy and high-strength steel. When traditional welding is used to combine aluminum and steel, electrochemical corrosion and changes in metal structure may occur, while SPR can perfectly avoid this problem.

Better structural strength and fatigue life

According to the internal test data of Rivmate, the shear strength of 6.3mm SPR is approximately 35% higher than that of spot welding of the same size, and its fatigue life is extended by more than 50%. This makes it an irreplaceable connection solution in the battery pack and Body-in-White structure of new energy vehicles.

Higher level of manufacturing automation

The SPR system can be integrated with robots to achieve high-rhythm production (capable of completing 15 to 20 riveting operations per minute). Compared with welding, the workstation noise is lower and the maintenance cycle is shorter, which is in line with the trend of intelligent manufacturing.

FAQs

What is a self piercing rivet and how does it work?

Self Piercing Rivet is a cold connection fastener that does not require pre-drilling. It completes the process of penetrating the upper layer material and locking the lower layer material in a single punching and riveting operation through a hydraulic or servo press, forming a high-strength mechanical interlocking. Unlike traditional riveting or welding, SPR does not produce heat-affected zones, and thus is particularly suitable for the connection of high-strength steel, aluminum alloys and composite materials.

Can self piercing rivets join aluminum to steel?

Yes. One of the greatest advantages of SPR technology is its ability to reliably connect dissimilar materials (such as aluminum + steel). Its unique punching and riveting principle enables it to form a locking cavity in the soft-layer aluminum plate through plastic forming after penetrating the hard-layer steel plate, thus achieving a firm bond. The Rivmate SPR system has been widely used in aluminum-steel hybrid structures in the assembly of automotive lightweight Body-in-White.

How strong are self piercing rivets?

The shear strength of SPR is usually between 8 and 12 kN, depending on the thickness and hardness of the material. Compared with spot welding, the fatigue life of SPR connections can be increased by 40-60%, and they still maintain excellent strength in multi-layer structures. This makes it an ideal choice to replace welding and enhance the durability of lightweight structures.

What tools are needed for self piercing rivets?

The installation of SPR requires a dedicated hydraulic riveting gun or servo press system, including the upper Die (Punch) and the lower die (Die). Rivmate offers fully automatic and semi-automatic SPR tool solutions, supporting robot integration to achieve continuous and high-rhythm production. For laboratory or small-batch applications, manual hydraulic punching and riveting equipment can also be used.

Are self piercing rivets reusable?

No. SPR belongs to permanent structural connectors. Once riveting is completed, it will form an undetachable mechanical locking structure. If demolition is required, it can be carried out by drilling or cutting. Compared with threaded connections, the design goal of SPR is to achieve highly reliable assembly with zero loosening and zero maintenance.

Build the Future with Rivmate Self Piercing Rivet Systems

Self Piercing Rivet is one of the core technologies of modern high-strength lightweight manufacturing. With the characteristics of no thermal effect, the ability to connect different materials and high fatigue life, it is gradually replacing traditional welding and riveting methods in the automotive, energy and aviation fields.

Visit Rivmate SPR Fastening Center to obtain: Technical parameters and samples of SPR rivets.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met