Are Rivets as Strong as Spot Welds?

Table of Contents

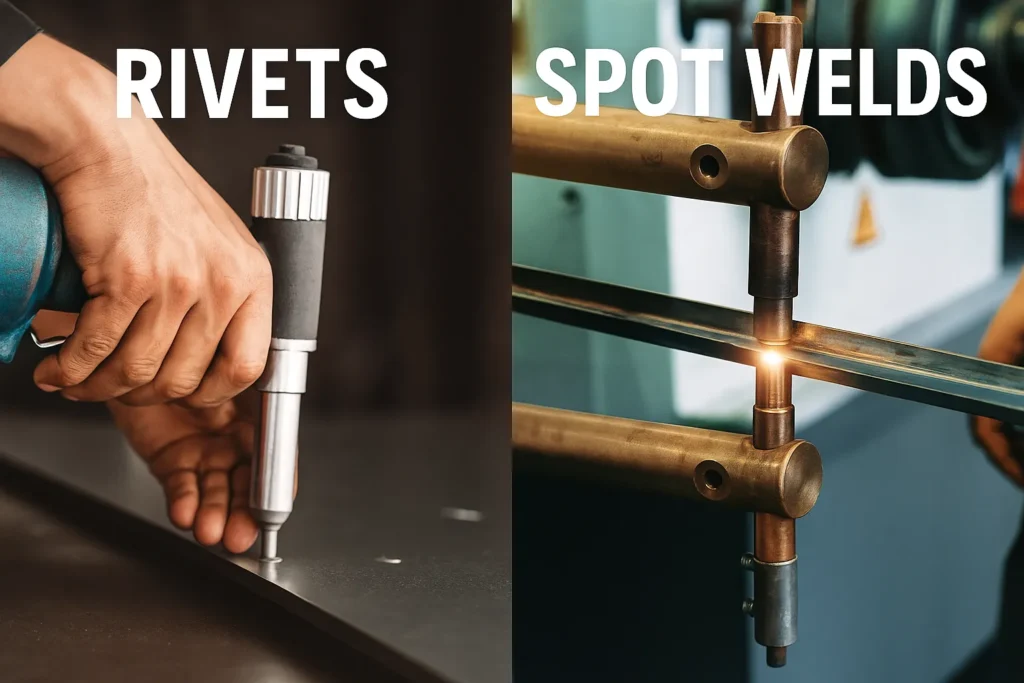

Are rivets as strong as spot welds? This is a question often raised by manufacturing engineers and designers. In modern manufacturing, riveting and spot welding are two common joining methods. Spot welding is renowned for its high strength and rapidity, while riveting is widely adopted in many fields due to its structural reliability and process flexibility.

However, there has always been controversy over which method is stronger. The traditional view holds that welded connections are more secure, but with the popularization of lightweight and multi-material structures, riveting technology (especially structural rivets and self-piercing rivets) has demonstrated more and more advantages. This blog will compare rivets and spot welding from three perspectives: strength, application scenarios, and engineering adaptability, to help readers make reasonable choices in actual projects.

What is Spot Welding?

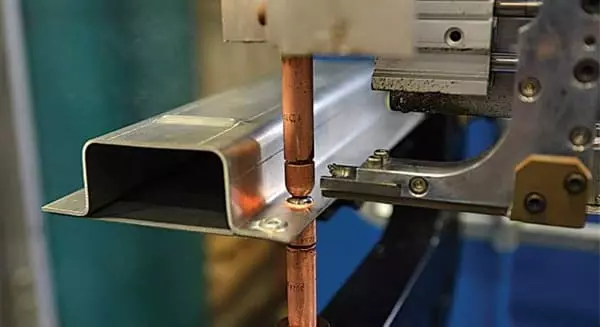

Spot welding is a common resistance welding process. Its core principle is to clamp metal plates with electrodes and pass a large current through them. Under the combined effect of pressure and resistive heat, the local metal at the contact point melts and solidifies rapidly, thus forming a strong weld spot.

a. Characteristics of Spot Welding

- High-intensity: The weld area is a metallurgical fusion, featuring excellent shear and peel resistance.

- Suitable for steel connections: Particularly suitable for low-carbon steel and stainless steel, commonly used in automotive bodies and sheet metal parts.

- High process efficiency: A single weld point typically takes only 0.1 to 0.3 seconds, making it highly suitable for mass production.

b. Limitations of Spot Welding

- Difficulties in welding aluminum and coated metals: Aluminum has high thermal conductivity, and the surface of coated materials hinders fusion, making it hard to ensure the strength of the weld points.

- Presence of heat-affected zone (HAZ): The welding process alters the microstructure of the material, which may lead to hardening, embrittlement or local deformation.

- High equipment investment and energy consumption: Specialized power supplies, water cooling systems and large-scale equipment are required, making it unsuitable for portable or on-site construction.

Research data indicates that in automotive manufacturing, the shear strength of a typical spot weld can reach 2 to 5 kN, but its performance depends on the welding current, pressure and material compatibility.

Riveting is a connection process achieved through the mechanical deformation of rivets. During installation, the shank of the rivet undergoes plastic deformation under external force, causing the tail to expand and compress the material layer, thereby forming a secure mechanical lock.

Classification of Riveting

Traditional Solid Rivets: Require double-sided operation and are mostly used in aircraft structures.

Blind Rivets: Can be installed on one side only, suitable for the fields of sheet metal, electronics and light industry.

Self-Piercing Rivets (SPR): No need for pre-drilling, can connect different materials such as aluminum and steel, or metal and composite materials.

Characteristics of Riveting

No need for heat source → No thermal affected zone (HAZ) will be formed, avoiding the degradation of metallic properties.

Suitable for different materials → Capable of achieving combinations such as aluminum + steel, metal + plastic that are difficult to achieve with spot welding.

Permanent mechanical connection → High strength, resistant to vibration, suitable for structures with long-term service life.

High controllability → The type, material and surface treatment of the rivets can be flexibly selected according to the application.

The single-point shear strength of structural rivets or SPRs can typically reach 1.5 – 4 kN. In the fields of lightweighting and multi-material integration, their performance is comparable to or even better than that of spot welding.

Rivets vs Spot Welds: Strength Comparison

The strength performance of rivets and spot welding depends on the force application method, material properties and working conditions. The following compares them from several key aspects:

Spot Welding: The local strength of the weld point is high, but its effect is limited to the weld core area. If the spacing between multiple weld points is too large, the overall shear resistance is limited.

Rivet: Multiple bolts can evenly distribute the load along the force path, resulting in better overall shear resistance. Research shows that the shear strength of the structure bolted at multiple points can be increased by more than 30% compared to single-point welding.

Spot Welding: The tensile strength is limited by the area of the weld point. Once the weld point is separated, the connection fails.

Rivet: The tension is directly borne by the bolt body. When arranged at multiple points, its tensile strength is often superior to that of single-point welding, and it is particularly suitable for large-area sheet components.

③ Fatigue Resistance

Spot Welding: The heat-affected zone (HAZ) is prone to cracking under cyclic loading, thereby limiting the fatigue life.

Rivet: The mechanical locking structure has better fatigue resistance. In actual tests in the automotive and aerospace industries, the fatigue life of the bolted joints is generally higher than that of the spot-welded joints.

④ Consistency

Spot Welding: The quality of the weld points depends on the stability of current, pressure and time. If the parameters fluctuate, the consistency of strength will decrease.

Rivet: The installation process is relatively controllable and is less affected by process parameters. It has high consistency and is suitable for mass assembly.

Beyond Strength: Other Considerations

| Factor | Riveted Joints | Spot Welding |

|---|---|---|

| Applicable Materials | Aluminum, Steel, Stainless Steel, Composites | Mainly suitable for Steel |

| Heat Source Required | No | Yes |

| Damage to Coatings | No | Yes (destroys protective coating) |

| Automation Compatibility | High (robotic SPR systems available) | High |

| Appearance & Aesthetics | Flat but visible rivet head | Smooth weld spot |

| Removability | No | No |

| Cost | Rivet + installation equipment | High energy consumption and equipment cost |

Industry Applications

Automotive

- High-strength steel structure → Traditional spot welding is widely used, with high weld strength, suitable for vehicle body frames.

- Aluminum body, composite materials → Spot welding is limited, and self-tapping rivets (SPR) have gradually become the mainstream. It can provide stable mechanical locking in combinations such as aluminum and steel, meeting the trend of lightweighting.

Aerospace

- Spot welding is limited in application because high temperatures can weaken the material properties.

- Bolting, especially for solid rivets and SPRs, is widely used in fuselage skins, wings, and composite components. They can maintain high reliability under vibration and extreme conditions.

Construction & Appliances

- For sheet connection, both spot welding and riveting can be used.

- However, in the application of coated metals (such as galvanized sheet, painted steel sheet), rivets have an advantage as they do not damage the anti-corrosion layer and extend the service life.

Rivmate Expert Recommendation

When choosing rivets or spot welding, it is necessary to comprehensively consider the material, process conditions and performance requirements. Rivmate suggests:

- If the material is steel and the production line is equipped with welding technology, spot welding is more cost-effective and can quickly achieve mass production.

- If it involves aluminum, different materials, or a pursuit of lightweight design, self-tapping rivets (SPR) is a better solution, as it avoids the limitations of spot welding in aluminum and composite materials.

- If there are higher requirements for consistency, fatigue resistance, and anti-corrosion performance, rivet connections are superior to spot welding, and are particularly suitable for long-term service structures such as aviation, automotive lightweighting, and building curtain walls.

Support Provided by Rivmate

Choice of Multiple Material Rivets: Available in steel, stainless steel and aluminum, meeting various application requirements.

Industry-specific Solution: For the automotive lightweighting, aerospace and construction industries, it offers high-strength connections.

Process Selection and Test Support: Through simulation experiments and parameter optimization, ensure the connection strength and long-term reliability.

FAQs

Q1: Can rivets completely replace spot welding?

Answer: No. In the mass production of steel, spot welding is still more economical and efficient. However, in the cases of aluminum materials, heterogeneous materials and lightweight applications, rivets (especially SPR) have become an important alternative to spot welding.

Q2: Which connection method is more lightweight?

Answer: Rivets are more suitable for lightweight designs. Especially the combination of aluminum alloy and steel, spot welding is difficult to achieve, while SPR can maintain strength while reducing weight.

Q3: Is SPR more expensive than spot welding?

Answer: The cost of a single SPR rivet is higher than that of a single solder joint. However, considering factors such as material compatibility, process consistency, and the cost of later anti-corrosion maintenance, SPR generally offers more advantages over the long term.

Q4: Can Rivmate assist in evaluating which process is more suitable for my project?

Answer: Yes. Rivmate offers process assessment, connection strength testing and selection guidance, helping customers make a reasonable choice between spot welding and riveting, and ensuring that the project achieves the best balance between performance and cost.

Discover the Best Joining Method for Your Project with Rivmate

Nails are not always stronger than spot welding in all cases. However, in terms of “multiple-point distribution, connection of different materials, and fatigue resistance”, nails are significantly superior to spot welding. Spot welding still holds an advantage in “steel structures and large-scale low-cost manufacturing” scenarios. The two are not mutually exclusive; rather, they should be selected appropriately based on “materials, working conditions, and costs”.

If you are in the process selection stage and unsure whether to choose rivets or spot welding, Rivmate can offer you professional support. We will provide customized solutions based on your material properties, production conditions and performance requirements, helping you make the best choice.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met