Rivet vs Screw - Difference Between Rivet and Screw

Table of Contents

Rivet vs screw, which is better? Although they are both the most common mechanical fastening methods, their working principles are completely different; an incorrect choice may lead to loosening, water seepage, structural failure, or even safety risks.

Based on Rivmate’s long-term practical experience in riveting in industries such as aviation, construction, automobiles, and home appliances, this article will systematically analyze the key differences between rivets and screws, helping you make the most accurate and reliable choice of fastening methods in different scenarios.

What Are Rivets and Screws?

Rivet

The rivets achieve connection through plastic deformation. During the installation process, the tail of the rivet is stretched or compressed and expanded, forming a permanent mechanical locking force. Therefore, the rivet is a non-detachable connection method, suitable for thin plates, metal structures, and environments with high vibration. Its strength comes from “the clamping force generated after deformation”, rather than the friction of the threads.

Screw

The screw achieves locking through the friction between the thread and the material. After being tightened, the thread engages with the inner wall of the hole, forming a detachable connection. This makes screws particularly suitable for structures that require later maintenance or repeated installation. However, due to the reliance on friction for locking, screws are prone to loosening in environments with vibration and impact.

From an engineering perspective, rivets fall under the category of “plastic locking”, while screws belong to “friction locking”. This is the fundamental reason for the significant differences in performance between the two in terms of vibration resistance, water resistance, and long-term reliability.

How Rivets and Screws Work

Understanding the working principles of Rivet and Screw is the core foundation for distinguishing the differences between them. Although both are used for mechanical connections, their internal force application methods are completely different, resulting in significant differences in structural strength, durability, and maintainability. Below, from an engineering perspective, we will provide a clear, concise, and professional explanation of the working mechanisms of both.

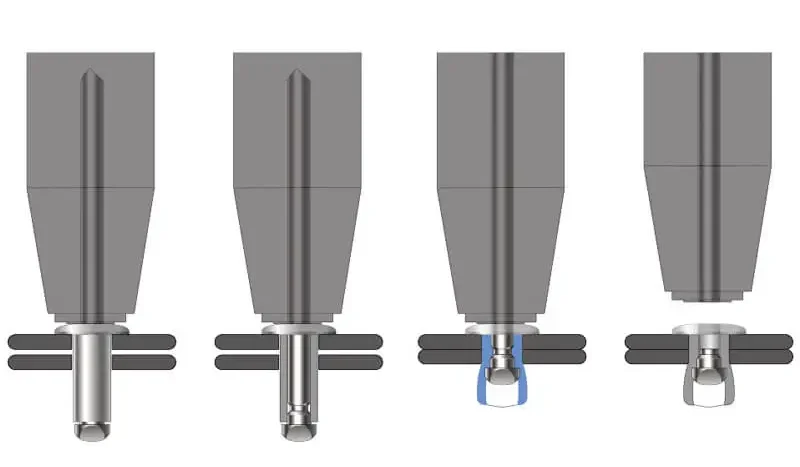

Rivet achieves clamping through plastic deformation. During installation, the riveting tool pulls the core shaft backward, causing the rivet tail to expand and compress the material. Its key features include:

- The expanded structure forms a permanent clamping force The tail end of the rivet is flared or expanded to form a stable mechanical lock.

- Non-detachable connection Once the rivets are formed, they cannot be removed without damaging the material. This makes them highly suitable for long-term fixation or for structures that are not maintainable.

- Applicable to thin plates, metal laminates and vibration environments The riveted structure is not prone to loosening under vibration. It is widely used in high-vibration environments such as aviation, automobiles, and roofing systems.

② The working principle of Screw: It relies on the friction of the thread for locking

Screw belongs to “detachable fastener“, and its working principle is completely different. Screws engage with the material through threads, creating friction or preload force, thereby achieving locking. The main features include:

- The friction of the thread generates locking force The friction between the thread and the hole wall keeps it fixed. It is more stable in metallic materials and tends to slip in soft materials or thin plates.

- Removable and Repairable The screws can be repeatedly tightened and loosened, making them ideal for structures that require regular maintenance.

- Higher requirements for the hardness of the material If the material is too thin or too soft, the threads will not be able to provide sufficient locking force. Therefore, in thin plate applications, rivets are usually more reliable than screws.

Difference Between Rivets and Screws

In real engineering selection, what users usually pay most attention to is not the structural principle itself, but the performance differences between the two under different working conditions. The comparison of performance dimensions can directly affect the reliability, maintenance cost and service life of the connection method.

| Performance Aspect | Rivet | Screw |

|---|---|---|

| Vibration Resistance | ★★★★★ Excellent | ★★★☆☆ Moderate (requires anti-loosening measures) |

| Shear Strength | ★★★★☆ High | ★★☆☆☆ Medium |

| Waterproofing | ★★★★★ Closed-end types can be fully sealed | ★★☆☆☆ Requires washer; still prone to leakage |

| Removability | ★☆☆☆☆ Non-removable | ★★★★★ Fully removable |

| Long-Term Stability | ★★★★★ Maintenance-free | ★★☆☆☆ Needs periodic retightening |

① Vibration Resistance

Rivet: Excellent performance, more stable structure

The rivets achieve “mechanical locking” through tail expansion, with uniform clamping force that does not rely on friction for stability. Therefore, they are less likely to loosen in long-term vibration conditions. They are suitable for high-vibration scenarios such as automobiles, rail transportation, roofing systems, mechanical equipment, etc. The Rivmate test shows that structural blind rivets do not loosen after 50,000 cycles of continuous vibration.

Screw: Medium, must adopt anti-loosening design

The screw maintains the locking force through the friction of the threads. Under continuous vibration, the frictional force decreases, increasing the risk of loosening.

- Common anti-loosening methods: spring washers, nylon locking nuts, threaded sealants, etc.

- If no anti-loosening measures are taken, the reliability of the screws will significantly decrease.

Conclusion: In high-temperature environments, Rivet should be the preferred choice.

② Shear Strength

Rivets are “solid metal structures” and have more stable bearing capacity when subjected to shear force. Especially for structural bolts (such as Monobolt, Hemlok, etc.), their shear strength can reach 1.5 to 3 times that of screws of the same specification.

Screw: Moderate shear resistance

The strength of the screw mainly depends on the area where the threads interlock. When subjected to lateral loads, the root of the thread is prone to fatigue or shear failure.

Conclusion: Scenarios that require the transmission of shear force are more suitable for Rivet.

③ Waterproofing Performance

Rivet: The closed-type rivet can provide a complete seal

The closed-end structure has a sealed tail end, which can prevent water vapor from entering. Combined with the EPDM gasket, it can achieve nearly 100% waterproofing. It is commonly used in:

- Roof system

- Exterior wall panels

- Air conditioning housing

- Ventilation equipment

Screw: Even with a washer, there is still a risk of water leakage

The screw itself does not have sealing capability. Even with the use of rubber gaskets, micro gaps may still occur in environments with thermal expansion and contraction or strong vibrations.

Conclusion: For outdoor environments, Rivet is the preferred choice; for structures prone to water seepage, Screw should be avoided.

④ Serviceability & Maintenance

Rivet: Non-detachable, suitable for permanent connection

Once the rivets are formed, they can only be removed by breaking them. This type of rivets is highly suitable for structures that do not require maintenance.

Screw: Removable and Reusable

The most notable advantage of screws is their ease of maintenance. They are suitable for product casings, repair components, electrical equipment, etc.

Conclusion: To be maintained → Screw; Not to be maintained → Rivet.

⑤ Service Life and Long-Term Stability

Rivet: Long-term stability and maintenance-free operation

The expansion structure is not prone to loosening due to vibration and has a long service life. It is suitable for long-term exposure, outdoor use, and industrial environments.

Screw: Periodic Inspection Required

Screws are greatly affected by temperature changes and vibrations, and their service life depends on the quality of maintenance.

Rivmate statistics: In outdoor applications, screws need to be re-tightened on average every 12-18 months; rivets do not require any maintenance during a 10-year usage period.

Best Material Compatibility for Rivets and Screws

In engineering assembly, the material properties often determine the final choice of fastening method. The thickness, strength and machinability of different materials will directly affect the performance and long-term stability of Rivet or Screw.

The clamping method of the rivets relies on the expansion at the tail end. Therefore, a relatively low hardness of the material is required, and it can perform stably in the following materials:

- Thin metal sheets (0.3 – 4 mm)

- Aluminum-magnesium alloy

- Plastic sheets (such as PC, ABS, PP)

- Composite materials (carbon fiber, glass fiber)

- Hollow structures or closed profiles

The reasons why rivets are more suitable for these materials are:

- The rivets do not rely on the material’s own thread strength: The tail expansion structure provides the clamping force, and the material body does not need to bear the shear force.

- It will not “slip” due to the softness of the material: For example, plastic, thin aluminum sheets, etc., because the material is soft, screws tend to slip, but rivets will not.

- It is suitable for structures where the back cannot be accessed (blind installation), such as door panels, pipes, interior cavities of vehicles, and cavity structures of curtain walls. Screws often cannot be installed in these places.

b. Screws are more suitable for medium-thick metals and hard materials

The screw locking relies on the interlocking of the threads and the material. Therefore, the strength performance depends on the hardness and thickness of the material. The applicable materials include:

- Medium-thick steel plate (> 1.5 mm)

- Hard aluminum plate (> 2 mm)

- Copper, brass

- Wood

- Engineering plastic (with self-drilling screw thread design)

Screws can perform well on these materials:

The material is thick enough to prevent the threads from being pulled off: The thread engagement depth is sufficient, and the locking force is stable.

The screws can be easily disassembled and reassembled, making them suitable for maintenance of structures such as equipment housings, electronic cavities, and mechanical covers.

c. Why do screws tend to "fail" when used on thin sheet materials?

On thin plates (< 1 mm), the thread engagement depth is insufficient. When the screw is screwed in, the force is concentrated in a very small area, resulting in: the thread being pulled apart; the plate deforming; ineffective locking cannot be achieved; loosening occurs during use. Especially for soft materials (such as aluminum, plastic), the thread slipping problem is more likely to occur.

d. Why are rivets more suitable for thin plates and soft materials?

The clamping force of the rivets comes from the expansion structure and does not depend on the hardness or thickness of the material. The features include:

- Capable of locking securely on extremely thin materials (0.3 – 0.5 mm)

- Suitable for multi-layer material combinations (such as metal + plastic)

- Will not fail due to the softness of the material

- Forms a long-term seismic structure that is more stable than screws

The Rivmate test indicates that when using screws in 0.8 mm sheet metal, the risk of loosening increases by approximately 47% within 6 months; however, when using blind rivets, there are no signs of loosening.

Advantages of Rivets Over Bolts

High vibration resistance and high shear resistance

The rivets achieve mechanical locking through expansion at the tail end, without relying on frictional force of the threads. Therefore, they maintain long-term stability even under continuous vibration or impact conditions. Applications: Vehicles, rail transportation, roofing systems, mechanical equipment.

Can form a permanent connection

Once formed, it cannot be loosened by itself and does not require maintenance. It is highly suitable for structural components where “loosening is not allowed”.

Outstanding waterproof and sealing capabilities

Especially the closed-end blind rivets (Closed-End) can completely prevent water vapor from entering. They are commonly used in applications that require sealing, such as exterior walls, roofs, HVAC systems, and electrical control boxes.

Can be used on extremely thin materials

It can still be reliably fastened on thin plates as thin as 0.3–0.5 mm, which is something screws cannot achieve. It is suitable for household appliance shells, metal furniture, electronic devices, etc.

Non-detachable

Once installed, it must be removed by destructive means. It is not suitable for structures that require regular maintenance.

Special tools are required

For example, manual riveting guns, electric riveting guns, structural riveting guns, etc. Although the operation is simple, additional equipment is still required.

Maintenance requires damaging the connection points

During the removal process, the materials may be damaged, requiring the need to drill new holes or use larger-sized tools.

3. Advantages of Screws

Re-usable and Detachable

This is the greatest advantage of this screw. It is suitable for applications that require maintenance, updates or regular servicing.

The materials and specifications are extremely diverse

Different head types, thread types, surface treatments and materials can be selected, with high adaptability. It is widely used in the fields of machinery, electronics and furniture.

Installation is simple and the tools are universal

Any electric drill or electric screwdriver can be used for installation. The cost of the tools is low and the learning curve is also low.

4. Disadvantages of Screws

It is prone to loosening and requires an additional anti-loosening design

In a vibrating environment, the frictional force of the threads will gradually decrease. The following must be ensured:

- Spring washer

- Locking nut

- Spacer plate

- Thread sealant

But it is still not as stable as the rivets.

Not suitable for thin sheet materials

Thin plates cannot provide sufficient thread engagement depth, which makes them prone to slipping or loosening. This is especially true for soft materials such as aluminum plates and plastic plates.

The waterproofing ability is limited

Around the screw holes, a small gap is prone to form. Even with the use of a washer, there is still a risk of water seepage. It is not recommended for use in outdoor waterproof structures.

When to Use Screws vs. Rivets

In actual engineering applications, the decision to use Rivet or Screw is not based on habit, but rather depends on factors such as material thickness, whether maintenance is required, environmental exposure conditions, load requirements, and sealing requirements.

| Application Scenario | Recommended Fastener | Reason |

|---|---|---|

| Sheet metal, roofing, exterior cladding systems | Rivet (Closed-End) | Requires high sealing performance and vibration resistance to prevent leakage and loosening. |

| Appliance housings, metal cabinets | Rivet | Thin material (0.3–1 mm); screws may strip threads. Rivets offer better stability. |

| Internal components requiring maintenance | Screw | Needs periodic disassembly; screws are fully reusable. |

| Pressure vessels, electrical enclosures, HVAC housings | Rivet (Sealed Type) | Requires airtight and watertight joints; rivets can provide complete sealing. |

| Furniture, wood, decorative materials | Screw | Easy to install, suitable for thicker or softer materials, and supports removability. |

Rivmate Expert Recommendations

Among various assembly scenarios, Rivet and Screw each have their own advantages. To assist users in making more efficient selections, the Rivmate engineering team, based on a large number of actual projects and material tests, has summarized the following concise, practical and directly applicable suggestions.

When you need to be waterproof, shockproof and want a long-term stable connection → choose Rivmate Blind Rivets

Blind rivets can be installed without the material’s back surface being accessible, and they achieve reliable locking through an expansion structure. The closed-type and structural-type rivets can also provide higher sealing and vibration resistance. Therefore, they are ideal choices for roof systems, exterior wall panels, HVAC enclosures, transportation equipment, and sheet metal structures.

When your structure requires disassembly, servicing or repeated maintenance → Choose Rivmate Stainless Steel Screws or Rivet Nuts

Screws and rivet nuts provide reusable threads, making them highly suitable for modular equipment, electronic enclosures, mechanical housings, and any applications requiring disassembly and maintenance. The stainless steel material also enhances corrosion resistance and overall lifespan, making it more reliable over the long term.

If the application scenario is complex and it is uncertain about the load, vibration or material compatibility → Contact the Rivmate engineering team directly

Complex working conditions usually require a more comprehensive data assessment, including material thickness, gripping range, environmental corrosion grade, shear and tensile strength requirements, etc. Rivmate engineers can conduct professional analysis based on your actual project and provide strength calculations and selection suggestions in accordance with ISO and DIN standards, ensuring that the final solution is safe, reliable, and cost-effective.

Get Expert Fastening Advice for Your Project

When choosing between Rivet and Screw, there is no single solution that is applicable to all structures. The correct approach is to make an engineering judgment based on factors such as material thickness, environmental conditions, load requirements, and maintenance methods. Whether you aim for higher water resistance, stronger vibration resistance, or a more flexible detachable structure, Rivmate can provide you with accurate and reliable advice.

If you are evaluating the appropriate fastening methods for your project, or need professional assessment of materials, strength, and clamping range, please feel free to contact the Rivmate engineering team. We can provide the following based on your application requirements:

- Personalized selection suggestions

- Material and structure assessment

- Comparison scheme of rivets and screws

- Analysis of engineering-level strength and lifespan

- Sample and batch supply plan

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met