Buy Stainless Steel Blind Rivets from Manufacturer

If you are seeking a high-quality stainless steel blind rivet manufacturer, you have come to the right place. As one of China’s leading producers of stainless steel blind rivets, we specialize in providing stable, reliable, and internationally compliant riveting solutions for industrial and engineering applications.

Regarding materials and processes, we utilize proven stainless steel materials and implement rigorous process control and inspection to ensure consistency in critical properties such as corrosion resistance, tensile strength, and shear strength. Our products are suitable for outdoor equipment, building structures, transportation, and scenarios demanding high hygiene or durability standards.

Additionally, we offer customization capabilities. We provide tailored solutions with varying specifications, head types, and material combinations based on application environments, load requirements, and assembly conditions.

Choosing us means gaining access to professional manufacturing capabilities, engineering support, and long-term reliable supply assurance. We welcome you to discuss your specific requirements with us.

Types of Stainless Steel Blind Rivets

Whether your project is for a light application or a heavy application that requires high strength. You are sure to find the right stainless steel blind rivet for your project at Rivmate.

Stainless Steel Open Type Blind Rivets

Stainless Steel Sealed Type Blind Rivets

Stainless Steel Uni-grip Blind Rivets

Stainless Steel Multi-grip Blind Rivets

Stainless Steel Interlock Rivets

Stainless Steel Monobolt Rivet

Stainless Steel Hemlok Rivets

Stainless Steel Q Rivets

Rivmate – The Top Stainless Steel Blind Rivets Manufactruer in China

Rivmate is one of China’s leading manufacturers and suppliers of pop rivets, offering a mature product portfolio and stable supply capabilities in stainless steel pop rivets. At Rivmate, you can access a complete series of stainless steel pop rivets covering diverse needs—from routine applications to high-strength structural connections.

Whether you require standard stainless steel pop rivets or high-strength structural rivets for critical structural components, we provide matching products and technical support. Beyond the products themselves, we prioritize application effectiveness. We deliver customized riveting solutions tailored to diverse working conditions, helping customers balance performance, cost, and assembly efficiency.

Rivmate products are widely adopted across multiple countries and regions, serving diverse industry clients. This commitment drives our adherence to rigorous production processes and meticulous quality inspection systems. Every stage—from raw materials to finished goods—undergoes effective control to ensure batch consistency and long-term reliability.

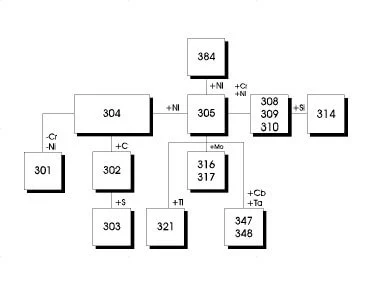

Types of Stainless Steel Blind Rivets Materials

We offer a variety of stainless steel material grades to meet diverse requirements for strength, corrosion resistance, and application environments. Through proper material selection, an optimal balance can be achieved between performance, service life, and cost.

302 Stainless Steel:Offers good strength and toughness, suitable for general-purpose stainless steel blind rivet applications.

304 Stainless Steel:The most commonly used grade, offering stable corrosion resistance suitable for most industrial and civil environments.

305 Stainless Steel:Features higher nickel content and superior cold forming properties, ideal for rivets requiring high forming consistency.

316 Stainless Steel:Offers superior corrosion resistance, particularly suited for marine, chemical, and high-humidity environments.

321 Stainless Steel:Provides excellent high-temperature resistance, ideal for applications involving thermal stress.

420 Stainless Steel:Offers high strength and hardness, suitable for applications requiring wear resistance and mechanical strength.

Types of Stainless Steel Blind Rivet Heads

In practical assembly, selecting the appropriate rivet head type is critical for connection effectiveness and finished product quality. Different head types emphasize distinct aspects of load-bearing capacity, visual appearance, and material protection.

- Countersunk Head: Flush with the surface after installation, suitable for applications requiring aesthetics, flatness, or subsequent overlaying.

- Dome Head: Offers high versatility and stable installation, suitable for most standard assemblies and structural connections.

- Large Flange Head: Provides a larger load-bearing surface, better protecting thin sheets or brittle materials. Ideal for soft substrates and scenarios requiring high safety margins.

Selecting the appropriate head type achieves the optimal balance between strength, appearance, and material protection. For any questions, please contact our engineering team for tailored selection support.

Material Combinations for Rivet Body and Rivets Mandrel

Rivmate not only manufactures all-stainless steel blind rivets but also offers blind rivets with various material combinations to meet diverse requirements for strength, corrosion resistance, and cost. By strategically pairing the rivet body and mandrel materials, we achieve precise matching for specific operating conditions.

- Aluminum / Stainless Steel: Aluminum body with stainless steel mandrel. Lightweight, smooth installation, balanced strength and corrosion resistance, suitable for light to medium-duty applications.

- Stainless Steel / Stainless Steel: All-stainless steel construction with superior corrosion resistance, ideal for humid or corrosive environments.

- Stainless Steel 304 / 420: 304 stainless steel body with 420 stainless steel mandrel. Maintains corrosion resistance while providing higher riveting strength.

- Stainless Steel 304 / 304: Full 304 stainless steel combination. Balanced performance suitable for most general stainless steel riveting applications.

- Stainless Steel 316 / 316: Utilizes 316 stainless steel for superior corrosion resistance, suitable for marine, chemical, and high-humidity environments.

Through diverse material combinations, Rivmate delivers flexible and reliable stainless steel blind rivet solutions for varied applications.

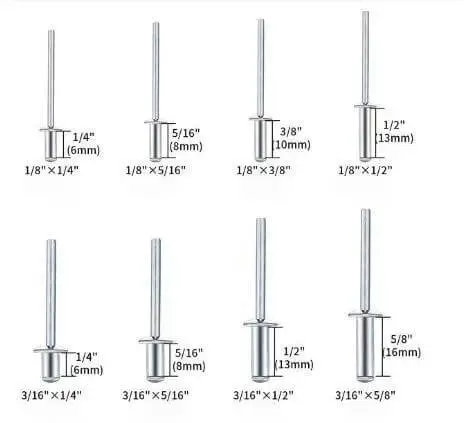

Various Sizes of Stainless Steel Blind Rivets Available

We offer a complete range of commonly used blind rivet specifications on the market to meet assembly requirements for varying material thicknesses and load demands. Common diameters include:

2.4 mm (3/32″), 3.2 mm (1/8″), 4.0 mm (5/32″), 4.8 mm (3/16″), and 6.4 mm (1/4″), covering mainstream applications from light-duty sheet metal connections to medium-load structural fastening.

In engineering selection, different diameters correspond to varying load capacities and installation conditions. We assist customers in choosing suitable specifications based on material type, total clamping thickness, and operating environment. Additionally, if standard sizes fail to meet your project requirements, we offer customization services, including non-standard diameters, lengths, and clamping ranges, ensuring optimal riveting performance and structural integrity.

Applications of Stainless Steel Blind Rivets

Stainless steel has very good corrosion resistance. Therefore it is widely used in various connection scenarios where strength and corrosion resistance are required. Below are some specific application scenarios for stainless steel blind rivets:

- Structural connections of hulls, decks, compartments and marine platforms

- Installation of façade panels, curtain wall systems, railings and guardrails

- Linking of body panels, fixing of chassis components and exhaust systems

- Installation and maintenance of piping systems, tanks and pressure vessels

- Assembly of kitchen equipment and food processing machinery

- Assembly of washing machines, dishwashers and other household appliances

Can You Get Stainless Steel Pop Rivets?

Yes. We offer a wide range of stainless steel blind rivets. As a top pop rivet manfuactruer in China, we can provide you with high quality stainless steel blind rivet. Of course, we can customise stainless steel blind rivet solution for your project.

Are Stainless Steel Blind Rivets Magnetic?

Whether a stainless steel blind rivet is magnetic or not depends on the type of stainless steel used. There are three main types of stainless steel:

- Austenitic stainless steel

- Martensitic stainless steel

- Ferritic stainless steel

Among the austenitic stainless steels, 304 stainless steel and 316 stainless steel are usually non-magnetic. The martensitic stainless steels 410 and 420 and the ferritic stainless steel 430 are magnetic. 410 and 420 stainless steels are the most magnetic.

How Much Weight Can a Stainless Steel Blind Rivet Hold?

The strength of stainless steel blind rivet mainly includes two aspects of rivet tensile strength and rivet shear strength.

Taking a stainless steel blind rivet with a diameter of 1/8 inch (about 3.2 mm) as an example, the following are some reference data:

- Tensile strength: approximately 350-450 kgf (approximately 770-990 lbf).

- Shear strength: approximately 250-350kg force (approximately 550-770lb force).

For larger diameter rivets (e.g. 3/16‘ or 1/4’), the load carrying capacity increases significantly.

What is the Difference Between Aluminum and Stainless Steel Blind Rivets?

The main differences between stainless steel blind rivet and aluminium blind rivets are as follows:

| Aluminum Blind Rivets | Stainless Steel Blind Rivets | |

| Material Properties | Lightweight, flexible, easy to process, moderate corrosion resistance | High strength, high hardness, excellent corrosion resistance, heavy weight |

| Strength | Low strength for low to medium stress connections | High strength for high stress connections |

| Corrosion Resistance | Moderately corrosion resistant to air and water, but not suitable for highly corrosive environments | Excellent corrosion resistance, suitable for marine, chemical and other harsh environments |

| Weights | Lightweight for applications with stringent weight requirements | Heavier for high-strength applications where weight is not a constraint |

| Cost | Lower cost for high volume use | Higher cost for more demanding applications |

| Applications | Lightweight structures such as aerospace, vehicles, electronic equipment | Heavy duty and structural applications such as construction, marine, chemical equipment |

| Suitable Environment | Low to medium corrosive environments, non-critical connections | Highly corrosive environments, harsh environments, highly stressed connections |

Not all stainless steel blind rivets are waterproof. Among them stainless steel closed end blind rivets are designed to be waterproof. It is ideal for sealed applications such as marine and roofing installations.

What Type of Stainless Steel Blind Rivet is Best for My Application?

The exact choice of stainless steel blind rivet depends on your actual application. If your project is in a corrosive environment, such as the marine or chemical industry, then 316 stainless steel blind rivet are the best choice. For general indoor applications or roof installations, 304 stainless steel blind rivet will suffice.

Can Stainless Steel Blind Rivet be Used in High Temperature Environments?

Sure. Stainless steel blind rivets have excellent heat resistance. Typically, stainless steel blind rivets can be used at temperatures up to 500 degrees Celsius. The exact temperature display depends on the type of stainless steel.

Below are the temperature ranges in which different stainless steel blind rivets can be used.

| Stainless Steel Type | Temperature Range |

| 304 Stainless Steel | -196°C ~ 870°C |

| 304L Stainless Steel | -196°C ~ 870°C |

| 316 Stainless Steel | -196°C ~ 800°C |

| 316L Stainless Steel | -196°C ~ 800°C |

| 310 Stainless Steel | -100°C ~ 1150°C |

| 410 Stainless Steel | -20°C ~ 700°C |

| 430 Stainless Steel | -20°C ~ 815°C |

Are Stainless Steel Blind Rivets Suitable for High Vibration Environments?

Of course. The most important feature of the blind rivets is that they have excellent anti-vibration properties. Stainless steel blind rivets are no exception. It provides a robust mechanical connection that is ideal for high vibration environments. Stainless steel blind rivets are often used to make connections in vehicles and mechanical equipment.

Do Stainless Steel Blind Rivets Require Special Maintenance?

Blind rivets generally require no special maintenance. However, in extremely corrosive environments the condition of the rivets should be checked periodically.

Can You Provide Samples of Stainless Steel Blind Rivets?

Sure! As a top pop rivet manufacturer in China, we can provide you with samples of any type of stainless steel blind rivets. In order to make sure that our products perfectly meet your needs. Before placing a formal order, you can ask us for samples for testing. Get the samples now!

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!