Table of Contents

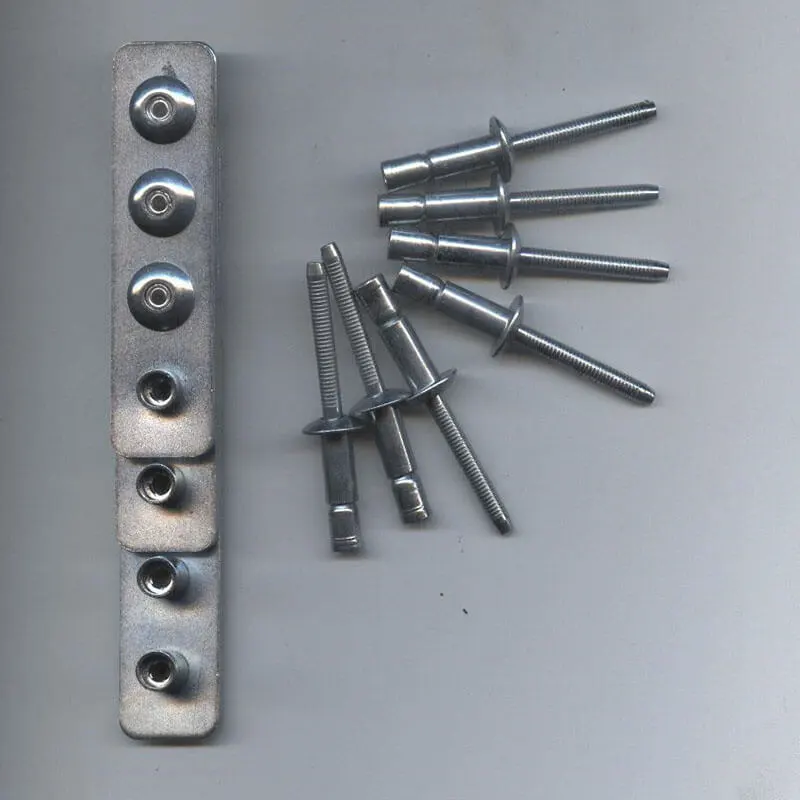

Exposed Rivet is a simple and efficient visual riveting system used in a wide range of industrial assemblies where structural joints are a priority and aesthetics are of moderate importance. If you are considering using Exposed Rivet in a new product assembly or as a replacement for an existing joint, I can assist with rivet construction evaluation and fitment selection.

This guide will show you specialized content around Mistakes to avoid when using exposed rivets.

Table of Contents

What are Exposed Rivets?

Exposed rivet is a form of riveting in which the rivet heads (cap) remains exposed on the surface of the material after the riveting is completed. This type of rivet connection is structurally stable, but the head of the rivet can be clearly seen visually, hence the name “exposed”.

Features of Exposed Rivets

- Rivet head is not hidden after installation and protrudes from the surface of the workpiece;

- Mostly used in one-sided installation scenarios without backside operation;

- Generally standard blind rivets (e.g. round head, flat head, large cap type, etc.);

- Easier to recognize and inspect than countersunk rivets or concealed connections.

What are the head types for exposed rivets?

Exposed rivets are categorized into three different head types based on the shape of the rivet cap. Each head type has different characteristics in terms of structural strength, aesthetics, contact area and assembly space.

- Dome Head

- Countersunk Head

- Large Flange Head

Do You Have Any Questions?

Let Us Solve Your Problem

Top 5 Mistakes to Avoid When Using Exposed Rivets

Exposed rivets are not simply “fastened and finished”, but a multi-dimensional issue covering structural strength, protective design, appearance management and process control. Especially in the field of outdoor, transportation equipment, building decoration, etc., it is more important to consider its long-term performance and maintenance cycle.

1. Corrosion protection must be clear

If your rivets and products are used in environments that are exposed to outdoor or humid conditions, then the blind rivets will be extremely susceptible to oxidization, rusting or corrosion and peeling.

So what if we respond to this situation? The countermeasures are as follows:

- Prefer stainless steel rivets, anodized aluminum or galvanized steel;

- Add surface treatments such as spraying, passivation, electrophoresis, and capping;

- For electrolytic corrosion scenarios (e.g. aluminum + steel structures) dissimilar metal contact needs to be prevented.

2. Matching of structural strength to direction of forces

In practice, when rivets are subjected to improperly oriented loads, such as shearing and pulling, the exposed connection is more likely to loosen or break.

So how should a loose connection due to this reason be solved?

- Ensure that the right rivet diameter, clamping range, head type and material are selected;

- For high load applications, it is recommended that structural rivets be used or reinforced with secondary shims/caps.

3. Aesthetics and layout need to be planned in advance

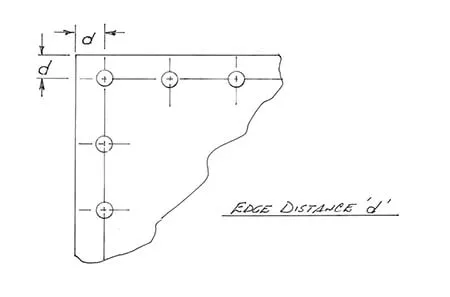

In load-bearing or high-strength structures, a large number of rivets are used to make connections. If the rivets are set in an unaligned position and at different heights, this can lead to an unreasonable strength design, which in turn affects the stability of the structure. If the head color of the rivets used on the agreed product does not agree, it may directly affect the visual perception of the finished product. Therefore, when setting a large number of blind rivets, you need to follow the following principles:

- Preset the row spacing and positioning holes in the drawing; (Read “rivet edge distance” for more information.)

- Use custom color rivet head or post-painting treatment;

- For the appearance of the surface can be added decorative caps.

4. Waterproof sealing measures should not be overlooked

In use environments where exposure to rainwater is possible, failure to seal around rivet holes may result in rainwater infiltration. This then leads to risks such as rust and leakage (particularly serious in electrical installations).

Countermeasures need to be employed to eliminate the occurrence of water seepage.

- Select closed type blind rivets (Sealed Blind Rivet);

- Match with waterproof gaskets or coated sealants;

- For outdoor structures it is recommended to apply a finished spray coating.

5. Avoid misuse of decorative instead of structural rivets

There are decorative “false rivets” or small exposed rivets used only for light load connection on the market, misused in the structural stress parts of the situation, which will produce safety hazards.

- Clearly distinguish between decorative rivets and industrial structural rivets in terms of specifications and certification;

- Use structural verification data for critical connections to support selection.

Do You Have Any Questions?

Let Us Solve Your Problem

FAQs about Using Exposed Rivets

Is it possible to seal or waterproof with exposed rivets?

Sure. Some waterproofing can be achieved by choosing rivets with gaskets or closed structures. But essentially the exposed structure is exposed to the environment and still needs to be protected with additional coatings/adhesive rings.

Do exposed rivets affect the appearance of the product?

Exposed rivets leave a visual bump when finished and are therefore not recommended for scenarios where a decorative or glossy finish is required.

Will Exposed rivets collect dust or rust easily?

Yes. The head portion of exposed rivets will corrode easily if exposed outdoors or in a wet environment without an anodized, galvanized or painted finish.

Is it possible to “hide” or overwrite exposed rivets?

The visual presence can be partially hidden or weakened by using decorative caps, spray paint, and film.

Get Rivets Quote

You may also find these topics interesting

Buy Open Type Blind Rivets

Buy Structural Blind Rivets