What Are Pop Rivets Used For?

Table of Contents

Pop rivets are among the most common and reliable blind fasteners in modern manufacturing. Their single-side installation, rapid assembly, and suitability for thin-sheet structures make them widely used across industries such as domestic appliances, automotive, construction, furniture, and sheet metal fabrication. What are pop rivets used for? Why do they often prove more stable, quicker, and more dependable than screws in thin-sheet connections? This guide will comprehensively explain the applications and selection logic of Pop Rivets from an engineer’s perspective, focusing on practical implementation.

What Are Pop Rivets?

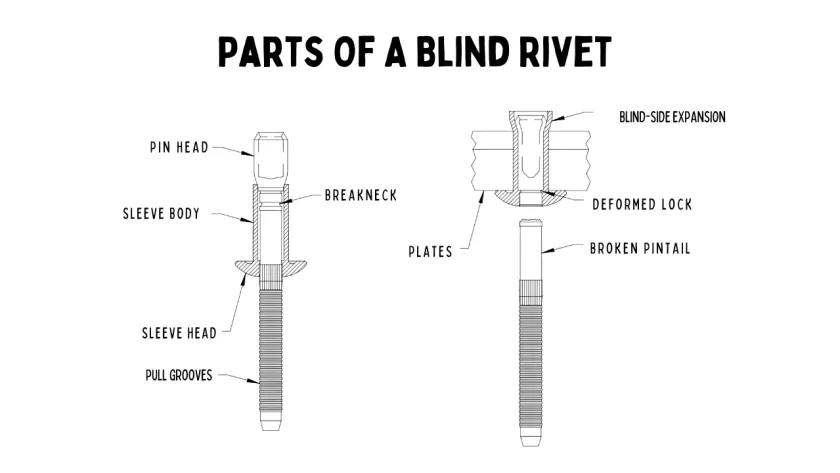

Pop rivets are a typical type of blind fastener, comprising two components: the body and the mandrel. The mandrel passes through the body and is drawn out during riveting, causing the body to undergo plastic expansion. This process creates a locking structure on the reverse side of the material, enabling connections where access is only possible from one side. This method is termed blind fastening (single-side installation / blind riveting).

Three key reasons make Pop Rivets particularly suitable for sheet metal applications. Firstly, thin sheets cannot support thread profiles, making screws prone to stripping; rivets, however, do not rely on thread engagement. Secondly, the expansion mechanism of Pop Rivets generates stable clamping forces across sheet thicknesses ranging from 0.3 to 3.0 millimetres. Thirdly, their rapid installation and consistent forming quality make them highly suitable for high-volume sheet metal production.

In summary, Pop Rivets represent a structurally simple, highly reliable fastening solution for single-sided sheet metal applications. They offer a more efficient alternative to screws and welding across numerous industries.

How Pop Rivets Work

The core mechanism of Pop Rivet can be divided into three steps: expansion, locking, and fracture.

a. Expansion Locking

The more fully expanded, the higher the locking force.

When the nail gun pulls the mandrel, the forming section at the tail end of the mandrel will be pulled into the cap body. The cap body then undergoes plastic expansion and forms a “hook” or “mushroom head” on the back of the sheet.

This expansion structure enables the Pop Rivet to achieve stable clamping force even in thin plates (0.3 – 3.0 mm).

b. Final Clamping Force

The location of the broken core determines the consistency of strength.

After the expansion process is completed, the core shaft will break at the preset fracture groove. The fracture position is strictly controlled to ensure that the rivets achieve the optimal expansion state and complete the final locking. Some of the core shafts will remain inside the cap body, enhancing the overall strength and improving the vibration resistance performance.

c. Why It Works for Sheet Metal?

Pop Rivet is a fastening solution specifically designed for “thin plates + single-sided installation”.

The main drawback of thin plates is that they cannot provide sufficient threaded engagement. Screws tend to slip and loosen in thin plates, and even tear the material. However, the locking force of Pop Rivets relies on the “expansion shape”, which is independent of the plate thickness. As long as the hole diameter is correct, a stable connection can be achieved. This gives Pop Rivets an absolute advantage in the following scenarios:

- Can only be operated from one side (blind fastening)

- The sheet material is too thin to drill holes

- Requires rapid and large-scale assembly

- Requires a long-term stable and vibration-resistant connection

Why Pop Rivets Are So Widely Used?

The reason why Pop Rivets are widely adopted in the global manufacturing industry is not because they are cheap, but because they possess technical advantages in thin plate structures that cannot be replaced by other fastening methods. These advantages directly determine the application scope and reliability of Pop Rivets.

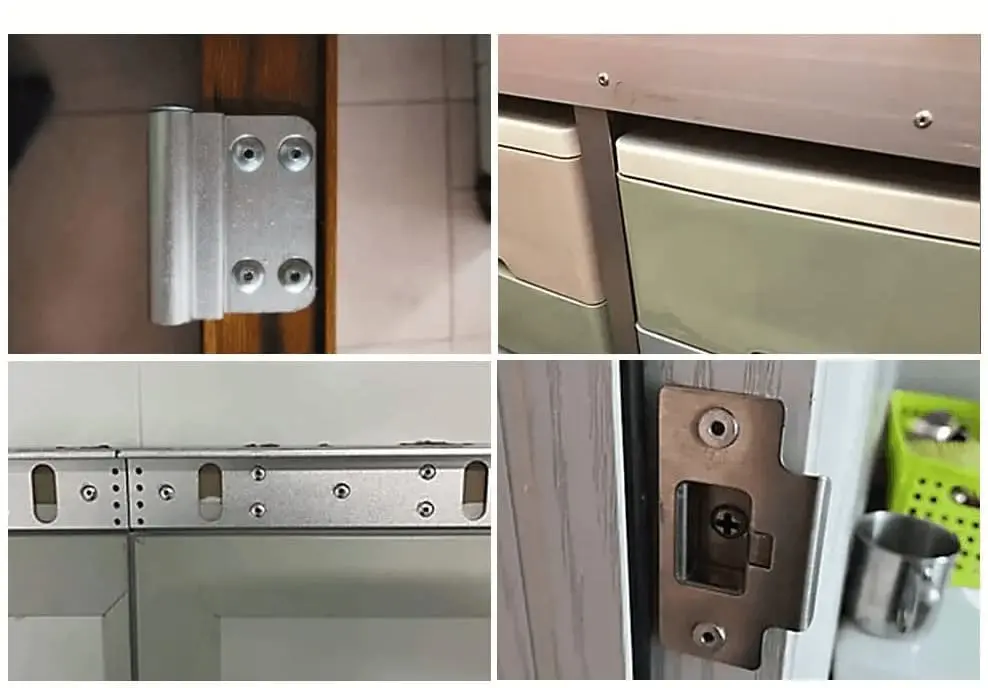

① Blind Installation, suitable for structures where access to the rear is not possible.

The greatest advantage of Pop Rivets is that “installation can be done from the front only”. Many structures are enclosed from the inside and their backs are inaccessible, such as metal shells, computer cases, and tubular profiles. Screws require bilateral engagement, while rivets do not.

② Gentle on thin sheets, it is one of the most reliable methods for joining thin sheets.

The riveting operation only takes 1–2 seconds. It is suitable for mass production on assembly lines and ensures high assembly consistency. Compared to threaded connections, no torque control is required, and there will be no deviations due to differences in operator skills.

③ It is friendly to thin plates and is one of the most reliable methods for connecting thin plates.

The thin plate cannot provide sufficient thread engagement, which will cause the screws to slip, loosen or even fall off. The clamping force of Pop Rivets relies on the “expansion structure” and does not depend on the depth of the thread. Therefore, they can be safely used in thin plates ranging from 0.3 to 3 mm.

④ Highly resistant to vibration, making it exceptionally well-suited for vibrating conditions.

The deformed metal after expansion will firmly lock the sheet, creating a long-term stable clamping state. Compared to screws, it will not loosen by itself due to vibration and does not require anti-loosening washers. This is why it is often used in: vehicle interiors, motor housings, HVAC, industrial equipment.

⑤ Low cost, yet no compromise on performance

The open-type aluminum rivets are one of the least costly industrial fasteners. The production method is cold heading automation, which is highly efficient, keeping their prices consistently within a very stable low range. They are suitable for mass production and cost-sensitive projects.

What Are Pop Rivets Used For: Industry Applications & Engineering Reasons

Pop rivets are used to fasten thin sheet-metal parts together from one side only, providing a quick, strong, and vibration-resistant connection.

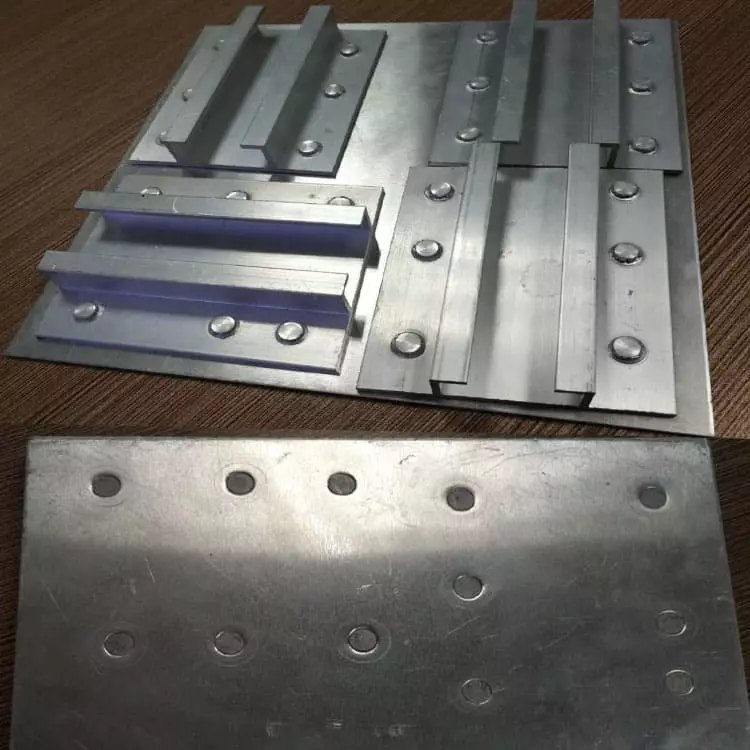

1. Sheet Metal Fabrication

Typical applications: HVAC enclosures, chassis cabinets, equipment covers.

The thickness of sheet metal is usually only 0.3–1.0 mm, which is insufficient to ensure reliable screw engagement. The screws will slip, loosen, or even fail to lock. However, Pop Rivets provide clamping force through an expansion structure, independent of the depth of the screw thread.

Reason for the project:

- Single-sided installation, suitable for enclosed sheet metal enclosures

- Stable connection strength for thin plates

- Resistant to loosening under prolonged vibration

- Closed-end design provides waterproofing and dustproofing

Suitable for areas subject to frequent vibration where disassembly is not required.

Typical applications: interior panels of vehicles, thin plate supports, wire harness fasteners.

The vibration of the vehicle is intense, and the screws are prone to loosening. Anti-loosening glue or washers are needed. Pop Rivets perform more stably in a vibrating environment, and they have low costs and fast batch installation speed.

Reason for the project:

- Excellent vibration resistance performance

- High installation consistency, beneficial for automotive assembly lines

- Aluminum rivets can reduce weight

- Can be used in composite structures made of thin steel plates and plastics

Suitable for areas that require frequent vibration but do not need to be disassembled.

Typical Application: Metal roofing, curtain wall system, ventilation ducts.

The exterior of the building is exposed to rain, ultraviolet rays, and temperature variations. Using screws may lead to water seepage or loosening. Pop Rivets (especially the closed type + EPDM gasket) can achieve complete sealing.

Reason for the project:

- Excellent sealing performance, preventing water leakage

- Resistant to loosening caused by temperature cycling

- Stainless steel/aluminum nails are corrosion-resistant

- Single-sided operation is suitable for roof construction

Outdoor + Metal Panels. Rivets are usually more reliable than screws.

4. Electronics & Appliances

Typical Application: Washing machine body, refrigerator panel, electrical control box body.

The sheet metal of household appliances is usually very thin (0.5 – 0.8 mm). The threads cannot provide a stable locking, and they will loosen with long-term vibration. Rivets offer higher structural reliability.

Reason for the project:

- Thin plates are not suitable for screws; rivets are more reliable.

- Mechanical and electrical equipment vibrates significantly (washing machines are especially so).

- Installation is fast, facilitating large-scale production.

- Aluminum rivets can prevent rusting and enhance the appearance lifespan.

Thin plates + vibration + high production line efficiency → Pop Rivets must be used.

Typical Applications: Aluminum profile frames, metal furniture, DIY toolboxes.

Maintenance and DIY users prefer Pop Rivets because the installation process is simple, requiring only a manual riveting gun. Screws need a threaded depth, while rivets are suitable for various thin-walled materials.

Reason for the project:

- No need for tapping

- No power supply required, nor welding equipment

- Aluminum profiles are suitable for aluminum rivets, aesthetically pleasing and rust-free

- Strong enough for light-load structures

Simple, fast and low-cost – these are the best features for DIY.

Typical Application: Lightweight structural components, skin panel connections, and vessel equipment shells.

In the early days of aviation, solid rivets were almost exclusively used. However, in non-critical structures, blind rivets were employed. For marine equipment, aluminum or stainless steel blind rivets are preferred.

Reason for the project:

- The rivets are more resistant to fatigue than screws.

- Light in weight (made of aluminum).

- The stainless steel rivets are resistant to seawater corrosion.

- The single-sided operation is suitable for complex structures.

When lightweight construction, corrosion resistance and long-term reliability are required, blind rivets offer superior performance.

Pop Rivets vs Screws vs Welding

| Comparison Aspect | Pop Rivet (Blind Rivet) | Screw | Welding |

|---|---|---|---|

| Cost | ★★★★☆ Low | ★★★☆☆ Medium | ★☆☆☆☆ High |

| Strength | ★★★☆☆ Moderate | ★★★★☆ Dependent on thread engagement | ★★★★★ Highest |

| Removability | ❌ Not removable | ✔ Removable and reusable | ❌ Not removable |

| Thin Sheet Suitability | ✔ Best choice | ✘ Prone to stripping | — |

| Material Compatibility | ✔ Metals + plastics | ✔ But requires thread engagement | ✘ Metals only |

| Water Resistance | ✔ Closed-end type can be sealed | ✘ Washers still risk leaking | ✔ Depends on welding quality |

| Vibration Resistance | ✔ Stable | ✘ Can loosen over time | ✔ Good, but welds may fatigue |

| Installation Difficulty | ★★☆☆☆ Easy | ★★★☆☆ Moderate | ★★★★★ Complex |

- Cost:

The Pop Rivets have the lowest cost and are suitable for mass production. The cost of screws is moderate, while welding is the most expensive as it involves labor, equipment, and inspection costs. - Strength:

The welding strength is the highest and can be used as the main structural connection. The strength of screws depends on the length of the thread engagement. Pop rivets perform stably in thin plates but are not suitable for extremely high loads. - Removability:

The screws can be easily removed and reinstalled. The Pop Rivets are non-disposable and need to be drilled out. Welding is completely non-reusable. - Material Compatibility:

Pop Rivets can be used to connect various materials such as metal and plastic. Screws require materials that can be tapped. Welding is only applicable to metal and the materials must be compatible. - Thickness Compatibility :

Pop Rivets are most suitable for thin boards with a thickness ranging from 0.3 to 3 mm. Screws are suitable for medium-thick boards. Welding is not limited by thickness. - Waterproofing Capacity: The closed-type Pop Rivets with EPDM can achieve a high level of sealing. However, the screws without additional washers may still allow water to seep through. Proper welding can provide a fully sealed result.

- Installation Difficulty:

The installation of Pop Rivets is the easiest, as it does not require contact with the backside. Screws need to be countersunk or have threaded structures. Welding installation is the most complex, requiring equipment and professional workers.

Types of Pop Rivets & Their Applications

Open-ended structures are the simplest and most cost-effective, meeting the majority of sheet metal fastening requirements.

Suitable industries: Light-duty applications such as household appliances, cabinets, and HVAC systems. Due to their rapid installation and high versatility, they represent the most widely used basic rivet type.

Closed-end design provides waterproof and dustproof protection, preventing corrosion caused by water ingress through the mandrel breakage point.

Suitable for outdoor structures such as roofing, external wall panels, electrical enclosures, and other applications demanding high sealing reliability.

Multi-grip rivets accommodate a wider range of plate thicknesses, with a single rivet replacing multiple specifications, thereby reducing inventory and selection risks.

Suitable for projects involving significant plate thickness variations or unstable on-site construction conditions.

The tail unfolds like petals, providing a large bearing surface that prevents tearing through the material.

Suitable for: Plastic, wood, FRP and other soft or brittle materials. The preferred rivet type for lightweight structures.

e. Structural Rivets / Monobolt

Structural rivets feature a mechanical locking mechanism, offering strength comparable to bolts and welded joints with exceptional vibration and impact resistance.

Suitable for: Automotive, machinery, rail transport and other heavy-duty structures, providing a professional-grade solution for high-strength applications.

FAQ: Common Questions About Pop Rivet Applications

Q1. What are pop rivets used for?

Pop rivets are widely used in thin-sheet structures such as sheet metal cabinets, domestic appliance casings, automotive interiors, and metal roofing, owing to their single-sided installation capability, rapid application, and stable joint formation.

For thin sheets, they offer exceptional strength, providing stable shear and tensile resistance; however, they are unsuitable for supporting primary structures or applications requiring extremely high strength, where structural rivets or welding must be employed.

Standard open-ended rivets are not waterproof. Closed-end rivets or sealed rivets with EPDM gaskets can achieve a high degree of waterproofing and are commonly used in roofing or outdoor equipment.

Cannot be removed directly; must be drilled out from the centre using a drill bit. After removal, rivets of the same or larger specification may be reinstalled.

Q5. What size pop rivet should I use?

Selection must be based on hole diameter, plate thickness (grip range), and strength requirements. The hole diameter should typically exceed the rivet diameter by 0.1–0.2 mm. The rivet length must cover the total plate thickness while ensuring sufficient expansion space.

Request Free Pop Rivet Samples & Expert Engineering Support

If you are selecting suitable pop rivets for your project, the most effective approach is to obtain direct access to engineer-level technical support and physical samples. Rivmate provides comprehensive assistance throughout the process, enabling more precise selection, better cost control, and more reliable structural integrity.

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met