How To Choose Blind Rivets for Automotive Manufacturing ?

Table of Contents

Automotive blind rivets have become a crucial fastening technology for achieving lightweight and high reliability. While welding offers high strength, it is only suitable for the same type of metal; while bolt connections are heavy and prone to loosening or fatigue failure under long-term vibration. In contrast, blind rivets offer advantages such as one-sided installation, high strength, maintenance-free, and automation, and are thus becoming the mainstream choice in automotive assembly. This article will comprehensively analyze how to select the most suitable automotive blind rivets.

What is an Automotive Blind Rivet?

a. Definition:

Automotive Blind Rivet (an automotive blind rivet) is a single-sided operation permanent mechanical fastener specifically designed for automotive manufacturing and structural assembly.

Unlike traditional bolts or welding, blind rivets can achieve high-strength connections in areas where only one side is accessible, and they are highly suitable for complex structures such as vehicle bodies, chassis, and electric vehicle battery packs.

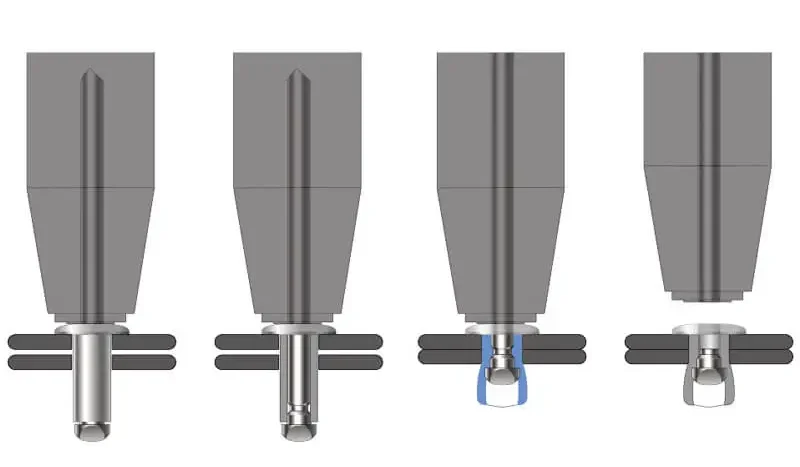

The blind rivet is composed of a rivet body and a mandrel. During installation, the mandrel is pulled by the riveting gun, causing the tail to undergo plastic deformation and forming an expansion locking structure on the back. At the same time, the mandrel breaks and locks itself in the rivet body.

This structure ensures that the joint after riveting has high tensile strength, good vibration resistance and consistency, and does not require any subsequent maintenance.

c. Technical Features and Advantages:

- No need for bilateral contact: Particularly suitable for the enclosed structures of vehicles (such as doors, columns, and inner cavities of the frame).

- Compatible with different materials (Aluminum + Steel): The blind rivets can easily achieve the mixed connection that is difficult to be realized through welding.

- High assembly efficiency: Supports automated production lines and can be integrated with robot systems.

- Light weight and high strength: Helps achieve the goal of body lightweighting.

Why Use Blind Rivets in Automotive Industry?

In modern automotive manufacturing, Blind Rivet has become a key technology replacing traditional welding and bolt connections. As the automotive industry transitions towards lightweighting, electrification and intelligent manufacturing, the blind riveting system, with its unique structural advantages and assembly efficiency, has become the preferred fastening solution for body engineers and manufacturing experts.

① Lightweight Manufacturing

With the widespread application of aluminum alloys and composite materials in vehicle bodies and battery packs, traditional welding methods have revealed significant limitations. Welding not only causes the thermal affected zone (HAZ) to occur, resulting in a decrease in material strength, but also easily leads to fatigue cracks in the aluminum structure.

In contrast, blind rivets do not require heating and can stably connect various materials such as “Aluminum + Steel” and “Aluminum + Composite”. They are an ideal choice for lightweight structures.

② Single-Side Installation Advantage

There are numerous enclosed cavities and narrow spaces in the structure of automobiles, such as the door panels, pillars, and longitudinal beams. The blind rivets can be easily installed from one side, achieving a strong connection. This significantly simplifies the assembly process, making it particularly suitable for robots or automated riveting equipment, thereby enhancing the overall production efficiency.

③ Vibration & Loosening Resistance

During the driving process, vehicles will endure continuous vibrations and dynamic loads. The blind rivets, with their core shaft locking structure, can effectively resist loosening and fatigue damage. In high-vibration areas such as the chassis, suspension, and power system, structural blind rivets perform particularly well.

④ Automation Compatibility

With the advancement of intelligent automotive manufacturing, automated assembly lines have become the mainstream. The blind riveting system can be seamlessly integrated with robot arms and numerical control systems to achieve rapid and high-precision batch riveting. Compared to traditional welding, it can increase the assembly cycle time by 25–40%, while reducing operational risks and energy consumption.

⑤ Multi-material Joining Capability

Modern vehicles widely adopt a mixed structure of aluminum, steel, magnesium alloys and plastic composite materials. Blind rivets can achieve reliable connections between different material thicknesses and hardnesses without changing the process parameters. This flexibility makes it the preferred solution for electric vehicles, battery packs and lightweight body structures.

Types of Automotive Blind Rivets and Their Applications

Different types of blind rivets have distinct characteristics in terms of performance, structural design and application scenarios. Engineers should make reasonable selections based on the material, force requirements and usage environment.

| Type | Features | Typical Applications |

|---|---|---|

| Open-End Rivet | General-purpose, cost-effective | Interior components, lightweight parts |

| Closed-End Rivet | Waterproof and corrosion-resistant | Chassis, door sills, door sealing areas |

| Structural Rivet | High tensile and shear strength | Body frame, longitudinal beams, suspension systems |

| Multi-Grip Rivet | Accommodates various thicknesses, reduces inventory | Modular assembly production lines |

| Hemlock / Monobolt Rivet | Locked mandrel, vibration-resistant | EV battery pack frames, vehicle frame connections |

Open-End Rivet

This is the most common type of blind rivets, featuring a simple structure, easy installation and low cost. It is suitable for light assembly scenarios such as interior components, door panels, and air conditioning pipe brackets. Although its strength is limited, it performs stably in areas that do not bear high vibration or heavy loads.

Advantages: Cost-effective and easy for mass assembly.

Disadvantage: It lacks waterproof and dustproof features. It is not recommended for use on the chassis or exterior parts.

Closed-End Rivet

This type is sealed at the tail, which can achieve a waterproof, dustproof and anti-corrosion sealing effect. It is widely used in areas such as car chassis, door sills, and door frames, and is especially suitable for structural environments that require water resistance and salt spray resistance.

Advantages: Possess excellent sealing performance and corrosion resistance.

Industry Application: It is commonly used in key areas such as car chassis, underbody panels, EV battery housing, etc.

Structural Rivet

This type of rivet structure is more robust, with the core shaft permanently locked in the rivet body, creating a high-strength mechanical lock. Its tensile and shear strengths are higher than those of standard blind rivets by 30% – 50%. It is widely used in high-stress areas such as the body-in-white structure, crossbeams, suspension brackets, and bumper frames.

Advantage: Extremely strong seismic resistance, suitable for long-term dynamic load conditions.

Multi-Grip Rivet

This type of rivets can cover different thickness ranges, reducing the variety of inventory and enhancing the flexibility of assembly. It is particularly common in automotive modular production lines and is suitable for connecting different combinations of component thicknesses.

Advantage: One type of rivet can replace multiple specifications, thereby reducing management costs.

Application: Dashboard frame, bracket, modular structure of car door.

Hemlock / Monobolt Rivet

This type of rivet core shaft is locked with the rivet body and has extremely high vibration resistance and anti-loosening performance. It is particularly suitable for the battery pack frame, chassis reinforcement components and safety structures of new energy vehicles.

Technical Advantages:

- After the core shaft is locked, it undergoes uniform radial expansion;

- It has high fatigue resistance;

- It is suitable for assembly of closed cavities and high-precision structures.

Best Materials for Automotive Blind Rivets

| Material | Key Characteristics | Recommended Applications | Rivmate Expert Tips |

|---|---|---|---|

| Aluminum Alloy | Lightweight, corrosion-resistant, excellent thermal conductivity; prevents galvanic corrosion. | Door panels, engine hoods, roof frames, aluminum body structures. | Ideal for lightweight vehicle designs. |

| Steel (Zinc-Plated) | High strength, impact-resistant, cost-effective; zinc coating provides rust protection. | Chassis components, suspension systems, mechanical supports, reinforcement beams. | High cost-performance ratio; use Structural Rivets for enhanced joint strength. |

| Stainless Steel (304 / 316) | Superior corrosion and fatigue resistance; performs well in salt spray and high-humidity environments. | Coastal vehicles, anti-corrosion chassis parts, exhaust systems, EV underbody panels. | Best for extreme environmental conditions. |

| Copper / Brass | Excellent electrical conductivity, corrosion resistance, and ductility. | Grounding connections, headlamp brackets, sensors, and control modules. | Recommended for electrical and electronic system assemblies. |

Key Applications of Blind Rivets in Automotive Manufacturing

a. Body-in-White Structure

The body-in-white (BIW) is the framework part of the entire vehicle, with extremely high requirements for strength and precision. Structural blind rivets are widely used to replace the traditional spot welding process. They can achieve reliable connections for various materials such as aluminum + steel and aluminum + composite materials.

- No need for high-temperature operation, avoiding welding deformation.

- The riveting strength is high, reaching 8–12kN.

- Suitable for automated assembly lines and seamlessly integrated with robot systems.

b. Chassis and Frame System

The chassis system is subjected to vibrations and impacts, and therefore has extremely high requirements for the shear strength and anti-loosening performance of fasteners. High-strength structural rivets are commonly used in the sub-frame, suspension brackets, longitudinal beam splicing, and torsion-resistant connection points.

- Excellent vibration resistance performance, preventing loosening.

- Stable performance over long-term use, no maintenance required.

- Rivmate test data shows that the fatigue life of structural rivets is 35% higher than that of bolts.

c. Electric Vehicle Battery Packs

The battery system of electric vehicles has extremely high requirements for air tightness, water resistance and corrosion prevention. The closed-end rivet is an ideal choice for connecting the battery casing, the base plate and the cooling system.

- Provides IP67 level waterproof and air-tight performance.

- Resists electrochemical corrosion and is suitable for aluminum battery casings.

- Compatible with automated assembly to ensure consistent assembly.

d. Interior & Door Assembly

In the interior decoration and door assembly of automobiles, blind rivets are used to connect the metal frame, plastic support, and decorative panel. The lightweight open-end rivet is widely adopted due to its low cost and ease of operation.

- Lightweight design effectively reduces the overall vehicle weight.

- No need for threading processing, and the assembly speed is fast.

- Compatible with automatic feeding systems, enhancing the production cycle.

FAQs

What are automotive blind rivets used for?

Blind rivets for automobiles are mainly used for permanent connections in the body, chassis, battery pack and interior systems. Compared with bolts or welding, blind rivets have advantages such as lightweight, single-side installation, vibration resistance, and corrosion resistance. They can connect aluminum, steel, plastic or composite materials without damaging the surface coating, and are highly suitable for modern vehicle assembly.

Can blind rivets replace welding in car bodies?

In most cases, structural blind rivets can replace the traditional spot welding process. They do not require high temperatures and avoid material thermal deformation, making them particularly suitable for aluminum + steel composite structures. Rivmate test data shows that the shear strength of structural blind rivets can reach 8–12kN, fully meeting the requirements for body-in-white (BIW) structural connections.

What material rivet is best for aluminum cars?

For aluminum vehicles, aluminum or stainless steel closed blind rivets are the best choice. Aluminum rivets can prevent electrochemical corrosion and maintain lightweight; while 316 stainless steel rivets are suitable for high-humidity or salt spray environments, such as in coastal areas.

How do you ensure rivet joints don’t loosen under vibration?

During the driving process, vehicles are constantly subjected to vibrations and impacts, and proper locking is crucial. Rivmate recommends using Lock-Core Structural Rivet or Monobolt Series, whose core shaft will be mechanically locked after being broken, thus maintaining a constant clamping force.

The actual measurement results show that this type of rivet shows no signs of loosening after 10⁶ cycles of vibration.

Are Rivmate blind rivets certified for automotive use?

- ISO/TS 16949 Automotive Quality System Certification

- ASTM B117 Salt Spray Corrosion Test (500h / 1000h)

- ISO 14589 Shear Strength Performance Standard

Optimize Automotive Structures with Rivmate Blind Rivets

Blind Rivets has become one of the most reliable and cost-effective structural connection methods in modern automotive manufacturing. Whether it is the body structure, the electric vehicle battery pack, or the chassis and interior system, blind rivets can perform exceptionally well in terms of lightweighting, vibration resistance, corrosion prevention, and automated assembly.

For manufacturing enterprises that pursue high-intensity production and high assembly consistency, the Rivmate Automotive Blind Rivet System offers the best solution that combines engineering performance with long-term stability.

Contact the professional team of Rivmate immediately to have them customize a dedicated fastening system solution for the key assembly parts such as the body, chassis, and battery pack for you.

reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met