How to Rivet Metal to Wood?

Table of Contents

How to Rivet Metal to Wood? Metal and wood are two completely different materials. Metal is hard while wood is soft, and when connecting them, difficulties are easily encountered. Common methods such as screws may gradually loosen due to the loosening of wood fibers; glue bonding lacks strength and durability; as for welding, it is even impossible to directly apply to wood.

How to achieve a strong bond between metal and wood? This article will offer you a comprehensive solution. We will detail the suitable types of rivets, tool selection, standardized operation procedures, and practical tips to avoid common problems. Rivmate, leveraging years of industry experience, will provide professional recommendations to help you achieve efficient and safe metal-wood riveting in various application scenarios.

Basic Concept of Riveting Metal to Wood

When it comes to the connection between metal and wood, many people may wonder: Why can rivets be used for both of these completely different materials at the same time?

Material Differences

Wood has a fibrous structure and is prone to cracking or deformation; while metal is hard and almost incompressible. This difference makes traditional screws or glue difficult to maintain stability over a long period. Screws may come loose due to the loosening of wood fibers, and glue cannot withstand large tensile or shear forces.

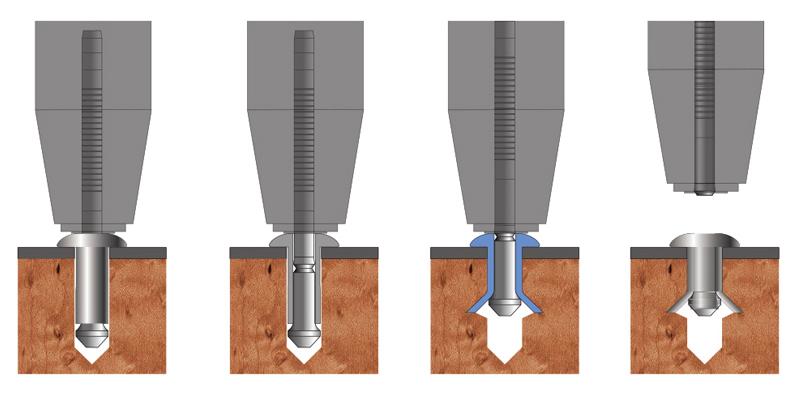

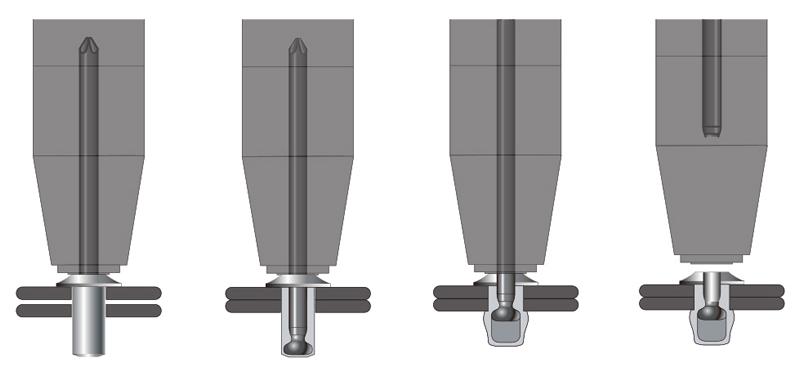

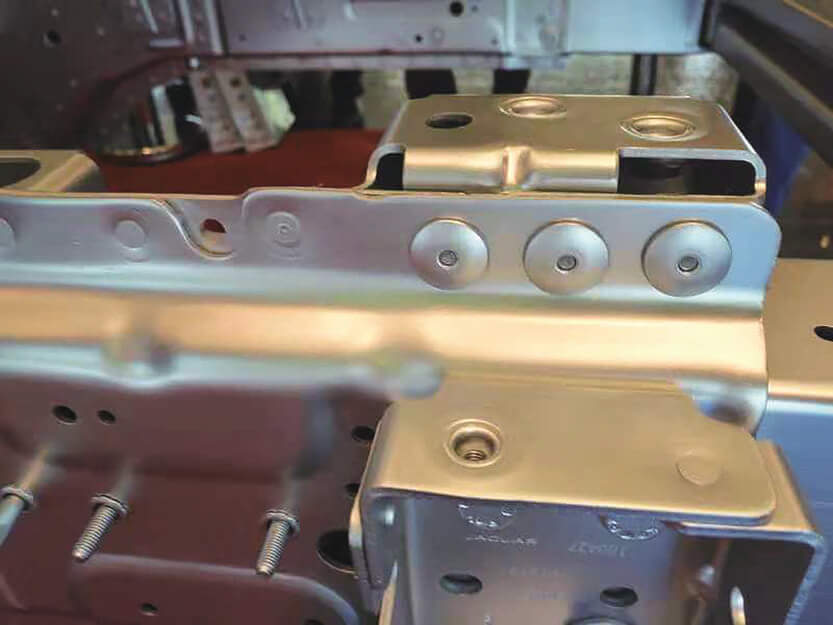

The Mechanism of Rivets' Function

The rivets in the connection do not merely “compress” the material; instead, they achieve a secure bond through “mechanical locking”. During installation, the tail end of the rivet undergoes plastic deformation, creating an “expansion” effect in the wood, while firmly fixing the metal in place. This method effectively disperses stress and reduces the risk of cracking in the wood due to excessive local stress.

Advantages of Riveting

- Cross-material compatibility: Suitable for the combination of hard metals and soft woods.

- Stress dispersion: Avoids single-point stress, enhancing the durability of the connection.

- Permanent fixation: Compared to screws and glue, riveting is more stable and has better vibration resistance.

Therefore, rivets not only solve the problem of combining metal with wood, but also offer a better solution in terms of structural strength and long-term reliability.

Challenges of Riveting Metal to Wood

Although riveting is an effective method for connecting metals and wood, there are still some challenges in practical operation. If these issues are ignored, the quality of the connection and its lifespan will be affected.

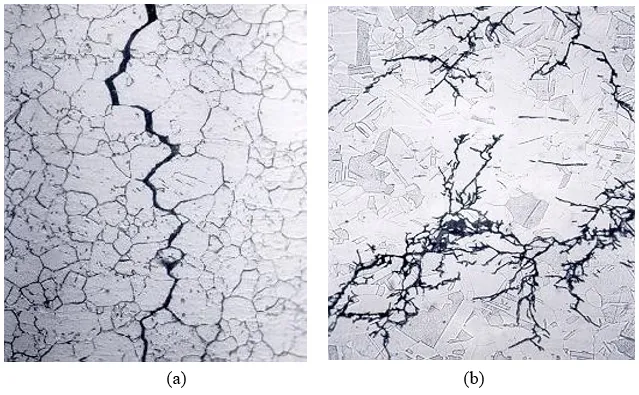

Material Differences: The wood fibers are relatively soft and are prone to cracking at the points of stress. In contrast, metals are hard and usually require precise pre-drilling. If the drill hole is too large, the rivets may not be able to securely fasten; if it is too small, the wood may split.

Fixed Issue: Ordinary rivets have insufficient grip in wood. Since wood does not provide uniform support like metal does, the expansion at the tail end of the rivet is prone to loosen within the wood. Over time, the connection may gradually fail.

Durability issue: Wood expands or contracts with changes in environmental humidity and temperature, which will impose additional stress on the riveted joints. If the rivets used are not corrosion-resistant or no protective measures are taken, they may loosen or even corrode over time during long-term use.

Best Rivets for Metal-to-Wood Connections

Choosing the appropriate rivets is crucial for achieving a secure bond between metal and wood. Different rivet designs are tailored to meet various structural requirements. The following are the most common types:

Suitable for single-side operation, especially in scenarios where the back side cannot be accessed. It is recommended to add a pad on the wood side to distribute the force and prevent the wood from being pulled through. It is commonly used in appliance assembly and lightweight structures.

The head area of the rivet is larger, which can disperse the pressure on the wood surface. This effectively prevents the wood from cracking due to excessive force on a specific area. It is particularly suitable for furniture manufacturing, as well as for the combination of wooden frames and metal parts.

A single rivet can adapt to different thickness combinations, reducing the risk of incorrect selection. It is suitable for situations where there is a significant difference in thickness between wood and metal. It is very practical in maintenance or DIY projects.

After being installed in the wood, stable threaded holes can be formed. This allows metal parts to be fixed onto the wood using bolts, enabling a detachable connection. It is suitable for projects that require later maintenance or adjustments, such as furniture and outdoor installations.

Rivmate Recommended Solution

Stainless steel large flange blind rivets: Possessing high strength and corrosion resistance, they prevent wood from cracking.

Rivmate Rivnut Series: Provides threaded fixation function for wood, expanding the application scenarios.

Tools Required

Completing the riveting of metal and wood requires not only the right rivets but also the correct tools. Choosing the right tools can enhance efficiency, reduce errors, and extend the service life of the structure.

- Suitable for small-scale DIY or repair tasks.

- Simple to operate, low in cost, and portable.

- The drawback is that the efficiency is relatively low. It is not suitable for large-scale riveting and may cause fatigue after long-term use.

2. Cordless Electric Rivet Gun

- Powered by batteries, it is lightweight and highly efficient.

- It is particularly suitable for woodworking workshops, on-site installation or small-scale production.

- The advantage lies in its high speed, no reliance on air source, and the ability to ensure high consistency.

3. Clamps and Fixtures

- Before riveting, the metal and wood must be firmly fixed.

- Avoid causing the wood to crack or the rivets to tilt due to uneven force.

- It is recommended to use an F-type fixture or a woodworking-specific press plate to stabilize the workpiece.

Rivmate Tool Recommendation

Rivmate’s compact Pneumatic blind riveting gun is specifically designed for use with metal and wood combinations:

- Lightweight in design, capable of operation in narrow spaces.

- Stable output, reducing the occurrence of poor rivet installation.

- Particularly outstanding in furniture manufacturing, outdoor structures and DIY projects.

Step-by-Step Guide: How to Rivet Metal to Wood

Step 1: Measure and mark the hole positions

Before starting, it is necessary to determine the joint position of the metal and the wood. Use a ruler to measure precisely and mark the points on the metal surface with a drill bit or a scriber to prevent the drill bit from slipping during drilling. For the wooden part, you can mark lightly with a pencil to avoid leaving scratches. The hole positions must be perfectly aligned; otherwise, the rivets will be installed unevenly, affecting the overall stability. In the case of multiple-point riveting, it is recommended to fix the workpiece with a fixture first, and then mark the positions uniformly.

Step 2: Pre-drilling

Drilling is a crucial step in riveting. For the metal parts, a high-speed steel drill bit (HSS) should be used, while for the wood, a dedicated woodworking drill bit is recommended to minimize fiber cracking. The hole size should be larger than the rivet diameter by 0.1–0.2 mm to ensure that the rivet can be inserted smoothly and form a tight fit. After drilling, carefully clean the burrs and wood chips. If the hole edge is not smooth, the rivet cap cannot be fully pressed in, which will cause the connection to loosen.

Step 3: Increase the gasket on the wood side

Because the wood is relatively soft, if direct riveting is used, the tail of the rivet may penetrate the wood. To avoid this situation, a large flange rivet or a metal gasket must be added on one side of the wood. The head area of the large flange rivet is larger, which can disperse the pressure and prevent excessive force on a specific area. For furniture manufacturing or outdoor structures, this step is particularly important as it can significantly enhance the durability and appearance of the riveting.

Step 4: Inserting Rivets

When inserting the rivets, it is essential to ensure that the rivet head is perfectly flush with the metal surface. The selection of the rivet length is very crucial. It should cover the total thickness of the metal and wood, and leave a margin of 1.5 times the diameter of the rivet body for the tail to deform. If the rivet is too short, it cannot provide a reliable fixation; if it is too long, the tail shape will be uneven, which will instead affect the strength. During insertion, check if the hole positions are aligned to avoid assembly failure due to misalignment.

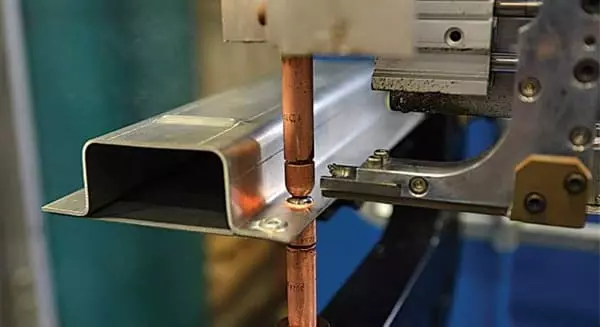

Step 5: Use a riveting gun to tighten

Select the appropriate riveting gun and align it with the core shaft. Keep the tool perpendicular to the workpiece. During the riveting process, the tail of the rivet will undergo plastic deformation until the core shaft breaks and the fixation is completed. Manual riveting guns are suitable for small-scale DIY projects, while electric or pneumatic riveting guns can provide more stable pulling force and ensure uniform tail expansion. During operation, avoid applying excessive force; otherwise, it may cause the wood to crack or the rivet head to be depressed.

Step 6: Check the Finished Product

After the riveting is completed, a comprehensive inspection must be carried out. First, check if there are any cracks or indentations on the wood. Then, confirm that the rivet head is tightly attached to the metal without any obvious gaps. The tail expansion should be uniform and full, neither skewed nor over-pulled through. If necessary, gently pull the workpiece to verify if the connection is secure. In industrial applications, tension tests or shear tests can also be conducted to ensure that the riveting strength meets the standards.

Common Mistakes & Troubleshooting

Wood cracking

Many users have found cracks at the edges of the wood during the riveting process. This is usually due to concentrated force or improper hole treatment. The solution is to use large flange rivets, as their contact area at the head is larger, which can disperse the pressure. Another method is to install metal gaskets at the hole openings of the wood, effectively reducing the concentration of tension.

Loose Rivets

If the rivets shake or are not firmly attached after installation, it is usually because the grip range was chosen incorrectly. Insufficient rivet length will result in incomplete tail formation. At this time, the correct specification that covers the total thickness should be selected, or a multi-grip range rivet should be used to accommodate different thickness metal-wood combinations.

Metal Deformation

During the operation, if the hole diameter is too large or the force applied by the riveting gun is uneven, the metal plate may develop dents or deformations. The solution is to ensure that the hole diameter precisely matches the diameter of the rivet (+0.1–0.2 mm), and keep the tool perpendicular to the workpiece. At the same time, avoid excessive force, especially when operating on thin metal plates.

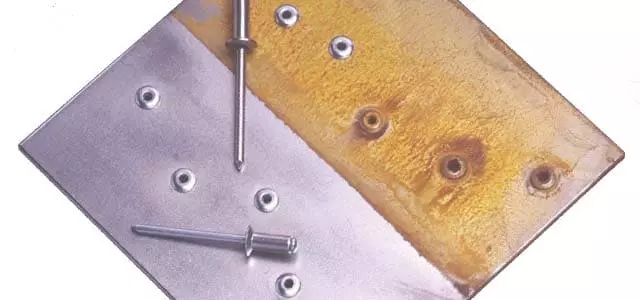

Environmental Corrosion

In outdoor or humid environments, ordinary rivets are prone to rusting and eventually fail. The solution is to use stainless steel or galvanized rivets, which have stronger corrosion resistance. If applied in marine environments, it is also recommended to use anti-corrosion wood to extend the overall structure’s lifespan.

Pro Tips from Rivmate

Precise control of hole size

When drilling holes in metal and wood, the diameter of the hole should be 0.1–0.2 mm larger than the diameter of the rivet. This ensures that the rivet can be inserted smoothly and fits tightly. If the hole is too large, the rivet will become loose; if it is too small, the wood may crack.

The Correct Way to Pre-drill Wood

When drilling wood, a woodworking drill bit should be used instead of a metal drill bit. The cutting angle of the woodworking drill bit can effectively reduce fiber tearing and prevent splitting. After the drilling is completed, the wood chips should be promptly cleaned up to keep the hole opening tidy.

Recommended solutions for outdoor applications

In an outdoor environment, wood will expand or contract due to humidity and temperature. If ordinary rivets are used, they are prone to corrosion or loosening. Rivmate suggests using treated wood + stainless steel rivets, as this combination can significantly extend the service life.

Improvement of Batch Job Efficiency

When performing batch metal-wood riveting in a factory or workshop, one should choose an air or electric riveting gun. Compared to manual tools, they can provide stable pulling force, ensure consistent shape, and reduce operator fatigue, thereby improving production efficiency.

FAQ

Q1: Can you rivet metal to wood without splitting the wood?

Sure. The key lies in controlling the drilling process and the force applied. When drilling, use a woodworking drill bit and ensure that the hole diameter matches the diameter of the rivet (+0.1 – 0.2 mm). During installation, it is best to choose a large flange rivet or add a metal gasket on the wood side to distribute the pressure and prevent the wood from cracking.

Q2: What is the best rivet type for metal-to-wood connections?

In most cases, the large flange blind rivets are the best choice as they provide a larger contact area and prevent the wood from being pulled through. If greater flexibility is required, the Multi-Grip Rivets can be used. If the project needs later maintenance, the Rivnut (threaded rivets) is also an ideal solution.

In terms of vibration resistance and long-term stability, rivets are usually more reliable than screws. Screws rely on the thread engagement in wood and may gradually fail as the wood fibers loosen. However, rivets achieve “mechanical locking” through the expansion of the tail end, making them more suitable for scenarios requiring long-term fixation. Nevertheless, if the connection needs to be detachable, screws are more convenient.

Q4: How do I prevent rivets from loosening in wood?

First, make sure to use the correct-sized rivets, especially the grip range must cover the total thickness of both the metal and the wood. Secondly, it is recommended to use a large flange head or gasket on the wood side to increase the grip force. Finally, choose stainless steel or galvanized rivets in humid environments to avoid corrosion and loosening.

Find the Right Metal-to-Wood Riveting Solution with Rivmate

Through proper aperture control, the selection of suitable rivets, and the use of professional tools, metal and wood can achieve stable and durable connections. Compared to screws or glue, riveting offers greater advantages in terms of vibration resistance and long-term reliability.

We have many years of industry experience and offer a full range of large flange blind rivets, Rivnut threaded rivets and professional riveting tools, which can meet various needs ranging from DIY to industrial applications.

Want to make the connection between your metal and wood more secure and durable? Please visit the Rivmate Technical Resource Center to obtain more professional guidelines and technical materials. You can also directly Contact the Rivmate Expert Team to get customized riveting solutions.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met