How to Rivet Metal to Metal

Table of Contents

How to rivet metal to metal? Whether in automotive body repair, construction steel assembly, mechanical structure fixation, or everyday DIY projects, metal-to-metal riveting is a common and reliable connection method. How to choose the right rivets? How to ensure sufficient strength and durability? If the operation is improper, how to avoid scrapping or rework? These questions are precisely the pain points for most users.

In this blog, we will address these issues from a professional perspective, step by step. The content covers the selection of tools, the matching of rivets, standardized operation procedures, and solutions to common errors. Rivmate, as an expert in riveting tools and fasteners, will combine industry experience to provide you with clear and actionable guidelines. Ensure that you can efficiently complete metal-to-metal riveting in various scenarios.

What is Riveting Metal to Metal?

“Riveting metal to metal” refers to the process of firmly connecting two or more metal plates together using rivets. This is a traditional method that is still widely used in mechanical connections.

Common Joining Methods:

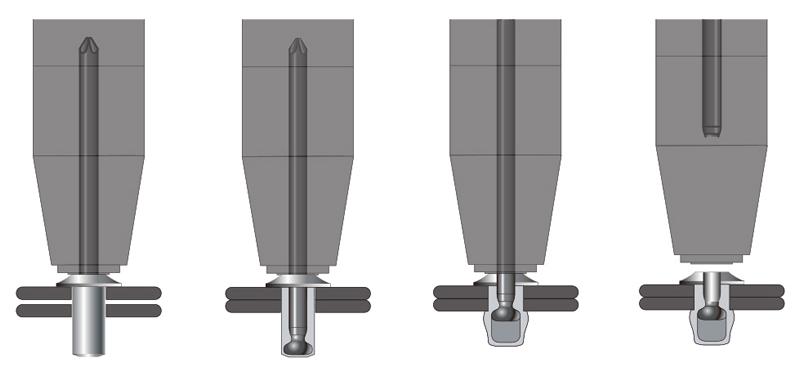

- Blind rivet: It breaks by relying on the mandrel, causing the tail end of the rivet to expand and compress the workpiece. The advantage is that it only requires a single-sided operation, making it very suitable for scenarios where the backside cannot be accessed.

- Solid rivet: Through hammering or hydraulic pressure, the tail end of the solid rivet undergoes plastic deformation, thereby tightly locking the metal parts together. This method is commonly used in aviation, bridges, and other structures with extremely high load requirements.

Riveting has unique advantages in metal-to-metal applications (compared with welding or bolt connections) :

- High strength: The rivets can provide reliable shear and tensile strength after forming.

- No heat-affected zone: Unlike welding, riveting does not alter the mechanical properties of the metal nor cause thermal deformation.

- Single-sided operation: Blind rivets are particularly suitable for workpieces where the backside is inaccessible.

- Long-term reliability: In environments with vibration and dynamic loads, riveting is more stable than threaded connections.

The rivets are of the non-detachable connection type. For later maintenance, the rivets need to be drilled out.

It is necessary to drill holes in advance, which will increase the process and may weaken the strength of the local material.

Therefore, riveting metal to metal is more suitable for scenarios that require high strength and long-term stability of connections, such as in automobile manufacturing, aerospace structures, building steel structures, and industrial equipment assembly.

Why Riveting Metal to Metal Is a Common Challenge

The riveting of metals to metals may seem simple, but in actual operation, it often presents numerous challenges. The main reasons include the following points:

- The material thickness varies greatly, making the selection of rivets quite complex.

Metal parts are often not of a single thickness. Different sheet materials combined make it difficult to precisely match the length and grip range of the rivets. If the rivets are too short, they cannot fix the workpiece; if they are too long, the tail may deform improperly. Studies show that over 30% of riveting failures are related to improper rivet selection. - The metal has high hardness, which increases the difficulty of drilling and forming.

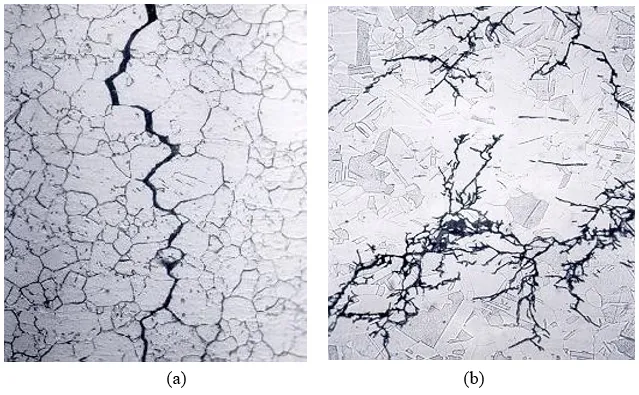

Hard metals such as steel and stainless steel require higher drilling forces. During drilling, the drill bit is prone to being burned or causing burrs on the hole wall. If the hole diameter is irregular, the rivets may not expand uniformly during the forming process, thereby reducing the connection strength. - Incorrect selection of the rivet size and grip range can easily lead to loosening or cracking.

Even if the installation is completed, if the grip range does not cover the total thickness of the material (TMT), the final connection will become loose. On the contrary, if the diameter or strength of the rivets is too large, the hard metal is prone to cracking or cracking at the hole mouth. - When performing batch riveting, the efficiency is low, and manual operation is unable to meet the production requirements.

In industrial manufacturing, metal riveting usually involves hundreds or even thousands of points. Relying solely on manual tools is not only inefficient but also causes operators to become fatigued and increases the rate of defective products. Therefore, in mass production, pneumatic or electric riveting guns must be introduced to maintain consistency and rhythm.

Tool Selection for Metal-to-Metal Riveting

In metal-to-metal riveting, the choice of tools directly affects the quality of the connection and the efficiency of the work. Different application scenarios require the use of different types of riveting guns.

a. Manual Rivet Gun

Suitable for small-scale DIY or repair tasks. The advantages are low cost and simple operation. However, the disadvantages are also obvious: when dealing with steel plates or stainless steel plates, the force application strength is often insufficient. Long-term operation can easily cause hand fatigue, and it is also difficult to ensure batch consistency.

b. Pneumatic/Hydraulic Rivet Gun

This is the main tool for industrial production. The pneumatic riveting gun is driven by compressed air and is suitable for large-scale and high-frequency riveting tasks. The hydraulic riveting gun can provide greater pulling force and is suitable for thick metals or high-strength rivets. The common advantages of both are high speed and high stability. However, additional energy systems and maintenance costs are required.

c. Cordless / Electric Rivet Gun

This tool has become increasingly popular in recent years. It combines the advantages of flexibility and efficiency, and is particularly suitable for on-site installation or maintenance tasks. The cordless design eliminates the limitations of power supply and air tubes, making the operation more flexible. The latest model also features intelligent control functions, which can monitor the tension and ensure that each riveting meets the standards.

Rivmate Recommended Tools

Rivmate offers a variety of optimized solutions specifically for metal riveting:

- Compact Electric Riveting Gun: Lightweight design, suitable for limited space and high-strength tasks.

- Industrial-grade Pneumatic Riveting Gun: High efficiency and long lifespan design, suitable for mass production and demanding industrial environments. These tools have all undergone rigorous testing to ensure their stable performance on hard metals such as steel and stainless steel.

Choosing the Right Rivet

In metal-to-metal riveting, the selection of rivets is as important as the tools. An incorrect choice can lead to loose connections, material damage, and even direct rework. Here are a few key points:

① Material Compatibility

The material of the rivets must match that of the base material.

- Aluminum rivets: Suitable for light metals or soft materials, they are lightweight but have limited strength.

- Steel rivets: Have high strength and are suitable for load-bearing structures, but require rust prevention treatment.

- Stainless steel rivets: Have strong corrosion resistance and are commonly used in outdoor, marine or aerospace structures.

If the material of the rivet is significantly different from that of the substrate, electrochemical corrosion is likely to occur. For instance, when an aluminum plate comes into contact with a steel rivet, it will accelerate the corrosion process in a humid environment.

② Rivet Diameter vs Hole Size

The hole size should be slightly larger than the diameter of the rivet body. The recommended value is diameter +0.1–0.2 mm. If the hole diameter is too large, the rivets will loosen; if it is too small, it may cause installation difficulties or damage to the hole wall.

The rivets must cover the total material thickness (TMT = plate thickness 1 + plate thickness 2 + coating/gap).

Ideally, the length of the rivet should be about 1.5 times the diameter larger than that of the TMT to ensure that the tail expands fully. Insufficient grip range will cause the rivet to fail to lock; an overly large grip range may result in incomplete formation.

- Blind Rivets: Suitable for scenarios where only one side can be operated, such as in sheet metal repair or sealing cavities. Installation is simple and they are the preferred choice for most industrial and DIY applications.

- Solid Rivets: Require access from both sides and are formed by hammering or hydraulic equipment. They have higher strength and are commonly used in high-load structures such as aviation and bridges.

⑤ Special Rivets

- Multi-grip Rivets: Cover various thicknesses, reducing the risk of incorrect selection, suitable for repairs or workpieces with inconsistent thickness.

- Closed-end Rivets: Can prevent the penetration of liquids or gases, commonly used in air conditioners, ships, and electronic equipment.

- Sealed Rivets: Provide additional protection in scenarios requiring corrosion prevention or sealing.

Step-by-Step Guide: How to Rivet Metal to Metal

The correct operation procedure is crucial for ensuring a secure and reliable metal-to-metal riveting. The following steps can serve as a standard reference:

Step 1: Measure and mark the hole positions

Accurately measure and mark the hole positions on the workpiece. It is recommended to use a scriber or a punch for positioning to prevent the drill bit from slipping. Inaccurate hole positions will result in uneven force distribution of the rivets, ultimately affecting the connection strength.

Step 2: Drilling and deburring

Drill holes according to the diameter of the rivets. The hole diameter should be larger than the rivet diameter by 0.1–0.2 mm. After drilling, the burrs must be removed to keep the hole opening smooth. If there are burrs inside the hole, the rivet cannot fit tightly, which may cause loosening or cracks.

Step 3: Select the appropriate rivets and check the Grip Range

Select the appropriate rivets based on the total material thickness (TMT). Ensure that the grip range covers the TMT and leaves a small safety margin. Rivets that are too short cannot be tightened properly, while those that are too long may result in incomplete formation.

Step 4: Insert the rivets and ensure that the cap portion fits snugly against the surface of the workpiece

Insert the rivet vertically into the hole. Check if the cap part is tightly against the surface of the workpiece. If there is any gap, the hole position needs to be re-adjusted or foreign objects need to be cleaned.

Step 5: Assembly Operation

- When using blind rivets, tighten them with a rivet gun until the core shaft breaks.

- When using solid rivets, shape the tail end through hammering or using hydraulic equipment. This step requires keeping the tool and the workpiece perpendicular to each other to avoid eccentric loading.

Step 6: Inspect the riveting quality

After completion, conduct an inspection of the appearance and structure:

- The head should be firmly attached to the surface without any looseness.

- The expansion on the back should be uniform and full, without any skewing.

- The workpiece should have no cracks or obvious deformations.

Troubleshooting

In metal-to-metal riveting, even with the use of the correct tools, problems often arise due to minor oversights. Here are some common mistakes and their solutions:

Too large aperture → Rivet loosen

When the hole diameter is larger than the recommended value (the diameter of the rivet body plus 0.2 mm or more), the rivet cannot be tightly locked onto the workpiece after forming, resulting in loose connection.

Solution: Replace with larger-sized rivets, or add a back-up washer on the back of the workpiece to provide additional support.

Short rivets → Unable to fix

When the length of the rivet is insufficient, the tail end cannot expand fully, resulting in loosening between the workpieces.

Solution: Determine the total material thickness (TMT), re-select the grip range to cover the TMT with the rivets, and appropriately lengthen it.

Surface after riveting is uneven → Might be due to improper alignment

If the rivets are not inserted vertically into the holes, or if the workpiece shifts during the riveting process, the heads will become uneven.

Solution: Before riveting, use jigs or Cleco temporary fasteners to fix the workpiece and ensure precise alignment.

Material cracking → Excessive diameter of the rivet or overly hard material

If overly large diameters or overly hard materials are chosen for the rivets, especially when used on thin metal sheets, it is likely to cause cracking at the hole openings or deformation of the sheets.

Solution: Replace with rivets of the appropriate diameter, or use multi-grip rivets. For soft materials, it is advisable to use large flange-head rivets to distribute the stress.

Pro Tips from Rivmate

In metal-to-metal riveting, details often determine success or failure. The following techniques have been summarized by Rivmate experts and can help you achieve a more stable and reliable riveting result in various scenarios.

The pre-drilled hole diameter should be 0.1–0.2 mm smaller than the diameter of the rivet body:

This is the key to ensuring strength. If the hole diameter is too large, the rivets will become loose and the shear strength will decrease. Research data shows that by keeping within the recommended tolerance range, the strength of the rivet connection can be increased by 15–20%.

Before riveting, always remove the burrs at the hole openings:

The burrs can cause the cap to not fully adhere to the workpiece, ultimately resulting in loose or uneven joints. It is recommended to use a deburring tool or fine file after drilling for processing.

When there is a coating on the metal surface, be sure to protect the openings:

When painting or coating metal and drilling holes, the hole openings are highly prone to damage, becoming sources of corrosion. The best practice is to apply a light seal or apply anti-rust paint at the hole openings to extend the lifespan of the joints.

Batch operations should prioritize the use of pneumatic or electric tools:

Manual riveting guns are sufficient for small-scale scenarios, but they are inefficient and prone to fatigue in batch operations. Using pneumatic or electric riveting guns can maintain consistent pulling force and forming quality, while reducing operation time by more than 30%, significantly enhancing production efficiency.

Rivmate Soft Promotion

In metal-to-metal riveting, choosing the right tools and rivets can significantly enhance efficiency and connection quality. Here are the professional recommendations from Rivmate:

Rivmate Industrial-grade Blind Riveting Gun

Suitable for high-intensity metal riveting tasks. Its high-strength design can easily handle hard materials such as steel plates and stainless steel. It performs particularly stably in mass production environments, reducing operator fatigue and defect rates.

Rivmate Multi-grip Rivets

A single rivet can cover different thickness ranges, reducing rework caused by incorrect selection of grip range. It is particularly suitable for repairs, modifications, or workpieces with uneven thickness. For users who frequently encounter complex applications, this is an ideal solution for reducing inventory and enhancing flexibility.

Rivmate Corrosion-Resistant Stainless Steel Rivets

Designed specifically for harsh environments, it boasts excellent corrosion resistance. It is commonly used in outdoor equipment, ship structures and aviation components. Even in high humidity or salt spray environments, it can maintain stable mechanical performance and a long service life.

FAQ

Q1: What is the strongest way to rivet metal to metal?

The most reliable method is usually to use solid rivets and form them with hydraulic or pneumatic equipment. This approach offers extremely high shear and tensile strength and is widely used in aviation, bridges, and heavy machinery. If a single-sided operation is required, then stainless steel blind rivets should be chosen to strike a balance between strength and convenience.

Q2: Can you use blind rivets for thick metal?

Sure, but the appropriate specifications need to be selected. The grip range of blind rivets must cover the total thickness of the material (TMT). For thick metals or multi-layer structures, it is recommended to use large-diameter blind rivets or multi-grip rivets. If the thickness exceeds the limit range of blind rivets, then consider using solid rivets or other mechanical connection methods instead.

When different metals come into contact, electrochemical corrosion is likely to occur. There are three solutions:

- Select rivets of the same material as the base material, for example, aluminum rivets for aluminum plates.

- Use insulating washers or coatings at the hole openings or contact surfaces to prevent electrochemical reactions.

- In outdoor or high-humidity environments, preferentially use stainless steel or anti-corrosion coated rivets.

Both have their own advantages:

- Riveting: Easy installation, can be operated on one side, no heat affected zone, suitable for thin plates, dissimilar metals and repair tasks.

- Welding: High strength, suitable for thick metals and high-load structures. However, welding creates a heat affected zone, which may alter the properties of the metal.

In scenarios where long-term stability and ease of operation are required, riveting is more suitable; in scenarios with extremely high load-bearing requirements, welding is superior.

Get Started with Rivmate Riveting Solutions

Metal-to-metal riveting is a reliable and efficient connection method, widely used in automobiles, aviation, construction and industrial manufacturing. As long as the rivet material, specification and tools are correctly selected, and the standard operating procedures are followed, the connection strength and long-term stability can be ensured.

As an industry expert, Rivmate has always been committed to providing high-quality riveting tools and fastening solutions. Whether for mass production, maintenance or modification, we can recommend the most suitable rivets and equipment for you.

👉 If you want to learn more about metal riveting techniques and product solutions? Please visit the Rivmate Technical Resource Center, or contact the Rivmate expert team for professional support.

reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Pop Rivet in Tight Spaces

How to Pop Rivet in Tight