How to Choose The Best Blind Rivet for Roofing ?

Table of Contents

The roof surface is constantly exposed to wind, temperature fluctuations and ultraviolet rays, which places extremely high demands on the waterproofing, corrosion resistance and structural stability of the fasteners. Compared to screws or welding methods, the Blind Rivet for Roofing (a special blind rivet for roofing) has become the preferred solution in metal roofing and light steel structure assembly due to its single-sided operation, reliable sealing, excellent seismic resistance and anti-loosening properties.

However, many roof leakage or corrosion problems do not originate from the roof panels themselves, but rather from the use of inappropriate rivet materials or incorrect installation methods. Rivmate has been deeply involved in blind riveting technology for over 15 years and has focused on providing industrial-grade waterproof Blind Rivets, successfully serving global roof system manufacturers and construction contractors worldwide. This article will systematically explain to you how to select the most suitable roof blind rivets based on environmental, structural and performance requirements, ensuring that your roof remains stable, leak-proof and durable in harsh environments.

Why Rivets Matter in Metal Roofing

In the metal roofing system, the connection method directly determines the durability and waterproofing performance. The reason why the “roofing blind rivet” is widely adopted lies in its ability to achieve stable, sealed, and lightweight connections on one side. This feature is particularly crucial for large-span roof panels, purlins, and inaccessible connection areas.

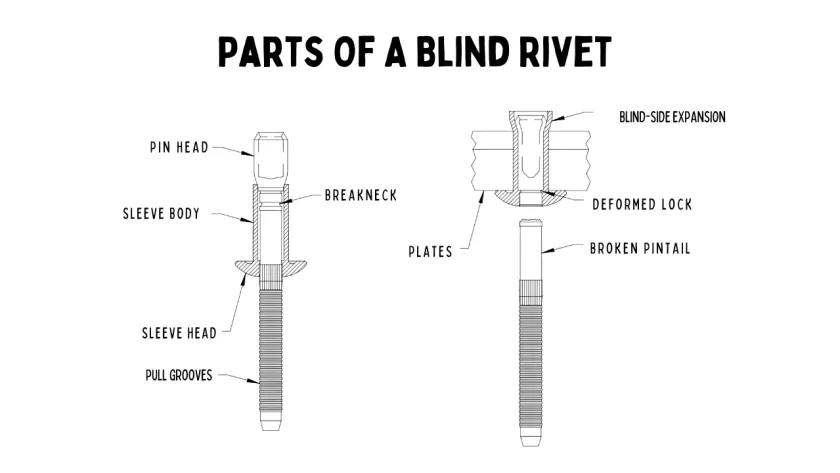

1) Basic Structure of Blind Rivets

- Shell/Body: The outer casing in contact with the roof panel. It is responsible for creating the mechanical locking of the “outer surface – back expansion” structure. Common cap types include round heads, countersunk heads, and sealing caps.

- Mandrel: Driven by a riveting gun. It causes the tail of the cap body to expand into a mushroom or umbrella-shaped supporting surface on the back of the sheet.

- Break Point: The core rod undergoes a controlled fracture at the specified pulling force. The fracture surface is flat, ensuring consistency in appearance and strength.

The result is: The cap body is firmly attached to the outer surface, and the back side expands uniformly. The strong connection is achieved without the need for operations on the back side. This is the core advantage when choosing the roofing fastener solution for roof applications.

① Single-Side Access

The joints of the metal roof panels, eaves, gutters, and the surrounding areas of equipment supports, as well as the backside, are often inaccessible. Blind rivets only require construction on the front side. This eliminates the need for backside washers or nuts. It enhances the safety and efficiency of high-altitude work.

② Maintain stable clamping force and resist thermal expansion and contraction

The roof panels are significantly affected by the temperature difference caused by sunlight. The linear expansion of the aluminum galvanized sheet occurs repeatedly throughout the year. The plastic forming + mechanical locking of blind rivets can provide stable clamping force, reducing the occurrence of minor loosening, abnormal sounds, and water leakage paths due to temperature changes. Under the same working conditions, the appropriate specification of structural or closed-type rivets can significantly reduce the risk of loosening.

③ Achievable Waterproof Sealing

Choose the closed-end (sealed) type, and pair it with EPDM/chloroprene rubber gaskets, which can form a continuous sealing path. Compared to ordinary screws, the plastic expansion around the riveted holes is more capable of filling tiny gaps. This is particularly beneficial for environments such as wind-driven rain, negative pressure suction, or melting snow and water. In practical engineering, the scheme of the closed-end type with a sealing gasket can meet the requirements of salt spray and rain test (refer to the test ideas of ASTM B117, ISO 9227, etc. for verification).

④ Efficient, lightweight, and maintenance-friendly

When the number of connection points per unit area is the same, the blind riveting method is usually lighter and does not require torque calibration. Electric/air-powered riveting guns can achieve one core break per shot in a continuous operation. For long-edge lap joints and flashing structures, it can significantly shorten the construction time and reduce the rework rate.

3) Comparison with Screws and Welding

- Sealing: Screws rely on the compression of the washer and the consistency of the torque; blind riveting can form multiple sealing paths through the combination of expansion molding and closed structure.

- Consistency: Screws are prone to slipping and torque fluctuations; the core-breaking tensile force of blind riveting is set by the tool, making it more standardized.

- Appearance and Looseness: The screw heads are high and the appearance is prone to inconsistency; the cap type of blind riveting is uniform, making it less likely to come loose. It is more friendly to micro-looseness caused by wind vibration and temperature differences.

- Applicability: Screws are easy to install and can be disassembled; blind riveting is a permanent connection, suitable for roof panel joints and edge pieces that do not need frequent disassembly.

- Heat affected zone: Welding will create a heat affected zone and damage to the coating, making it a potential starting point for corrosion; blind riveting is a cold process, more friendly to the coating and plating of the sheet.

- Construction conditions: Welding requires power supply, gas, fire prevention measures and skilled welders; blind riveting is lightweight, more accommodating to weather and on-site conditions.

- Appearance and deformation: Welding may cause local curving and discoloration; blind riveting results in less deformation of the panel and controllable final appearance.

- Overall cost: Considering fire prevention, surface repair, quality inspection and rework, the overall construction cost of blind riveting is more competitive in roofing and enclosure systems.

Common Metal Roofing Rivet Types

In the metal roofing system, choosing the right blind rivets for roofing is of utmost importance. Different types of rivets vary significantly in terms of waterproofing performance, structural strength, and weather resistance. Incorrect selection may result in roof leakage, corrosion spread, or connection fatigue failure.

The following will introduce, from a professional perspective, the four most commonly used types of roof-specific rivets, and illustrate their performance characteristics and selection guidelines through practical application cases.

The closed-type rivet (also known as a waterproof rivet) completely seals the bottom of the cap body. After the core shaft breaks, it remains inside and does not form a through hole. This design enables 100% waterproof and air-sealing, and it is one of the most commonly used fastening solutions in metal roofing systems.

Performance Advantages:

- Completely prevent leakage caused by rainwater, condensation water or wind pressure backflow.

- The core shaft locking structure enhances tensile strength and vibration resistance.

- It can be combined with EPDM sealing gaskets to form a double protective layer.

Material Selection Suggestions:

It is recommended to adopt the combination of aluminum alloy cap body and stainless steel core shaft, which can achieve both corrosion prevention and strength. For use in coastal areas or high-humidity environments, the fully stainless steel enclosed type can be selected.

Typical Application Scenarios:

- The connection point between the ridge cover plate and the flashing structure

- The edges of the drainage groove and the skylight

- Roof maintenance or renovation projects

The stainless steel blind rivets are made of A2 or A4 grade stainless steel and possess extremely high corrosion resistance and shear strength. They can maintain structural stability for a long time in high-salt or acidic environments.

Performance Advantages:

- Rust-proof and resistant to electrochemical corrosion, suitable for marine and chemical industrial areas.

- High mechanical strength, ensuring no loosening during long-term use.

- Capable of withstanding extreme climatic conditions such as high and low temperatures.

Material Combination Suggestions:

- All Stainless (Stainless–Stainless): The highest level of corrosion resistance, suitable for exposed rooftops.

- Steel Core Shaft + Aluminum Cap Body (Steel–Aluminum): Achieves a balance between strength and cost.

Typical Application Scenarios:

- Coastal building roof

- Industrial plant exhaust hood and support structure

- High-humidity cold storage system

The colored rivets are made using the polyester powder coating or epoxy resin baking paint process, and their colors are consistent with those of the roof panels, meeting the aesthetic and protective requirements of modern architecture.

Performance Advantages:

- Excellent color matching, visually harmonious, no need for additional painting.

- The coating has UV resistance and anti-fading properties, remaining unchanged even after long-term exposure.

- An additional anti-corrosion protective layer is provided to delay oxidation.

Materials and Coating Process Recommendations:

- The cap body is made of aluminum alloy, and the surface is electrostatically sprayed with RAL standard colors.

- The recommended thickness of the outer coating is ≥ 25μm, which can effectively prevent moisture and ultraviolet rays from penetrating.

Typical Application Scenarios:

- Commercial building roofing system

- Residential decorative metal roofing

- Building curtain wall and exterior facade decoration fixation

Structural rivets are a type of high-strength, vibration-resistant permanent fastener. After the core shaft breaks, it will be mechanically locked in the cap body, thereby enhancing the shear and tensile strength. They are suitable for load-bearing parts such as steel purlins and support frameworks under the roof.

Performance Advantages:

- The shear strength is more than three times that of ordinary aluminum rivets.

- The core shaft is securely locked and does not come off, preventing loosening caused by long-term vibration.

- No welding is required, and it can quickly replace the traditional bolt structure.

Material and Structure Suggestions:

- Stainless steel cap body + steel core shaft: High strength, suitable for structural joints.

- Double-lock type (Lock-Bolt Type) structure: The broken core is fully locked, enhancing fatigue life.

Typical Application Scenarios:

- Fixation of roof trusses and beams in steel structures

- Installation bases for photovoltaic supports and equipment

- Construction projects in areas with high wind pressure or seismic zones

Rivmate Roofing Rivet Selection Chart

| Rivet Type | Waterproof Rating | Corrosion Resistance | Tensile Strength | Recommended Applications |

|---|---|---|---|---|

| Sealed Rivet (Closed-End) | ★★★★★ | ★★★★☆ | Medium | Ridge caps, flashing, waterproof panel joints |

| Stainless Steel Rivet | ★★★★☆ | ★★★★★ | High | Coastal areas, high humidity environments, industrial roofs |

| Color-Coated Rivet | ★★★★☆ | ★★★★☆ | Medium | Decorative roofing, architectural façades |

| Structural Rivet | ★★★★☆ | ★★★★★ | Very High | Steel purlins, solar mounting systems, load-bearing connections |

Essential Rivet Selection Criteria

Choosing the appropriate “blind rivet for roofing” is not only related to the waterproofing performance, but also directly affects the structural stability and service life of the roofing system.

The following four core standards are the key factors that every construction engineer or purchasing manager must consider when choosing roof rivets.

a. Material Compatibility

The roof structure is usually composed of different materials, such as galvanized aluminum sheets, stainless steel plates, steel purlins, etc. There is an electrochemical potential difference between different metals. If the rivet material is improperly selected, galvanic corrosion will occur, which will accelerate the corrosion process.

- The material of the rivets should be as close to the potential of the riveted material as possible.

- For aluminum roofing → Choose either “aluminum + aluminum” or “aluminum + stainless steel core shaft”.

- For stainless steel roofing → Use “fully stainless rivets (Stainless–Stainless)”.

- Avoid using the combination of “aluminum + carbon steel”, as the corrosion rate will increase by 3-5 times in humid or coastal areas.

- For different metal combinations, add “anti-corrosion gaskets or coating isolation membranes” to the contact surfaces.

The rivet series of Rivmate have all passed the ISO 9227 salt spray test, ensuring that the combined materials maintain structural stability for over 500 hours.

b. Load-Bearing Strength

The roof connection not only bears the self-weight but also has to withstand long-term alternating loads such as wind load, snow load, and thermal expansion and contraction stress. If the tensile strength of the rivets is insufficient, it is prone to loosening, core breakage or cracking of the board seams.

- When selecting the type, the minimum tensile strength of the required rivets should be calculated based on the roof design wind pressure (kN/m²) and the plate thickness.

- Common aluminum rivets: 600–800 N

- Stainless steel rivets: 900–1200 N

- Structural rivets: ≥1500 N

- If the roof is located in a high wind area (such as coastal areas or high-rise buildings), structural blind rivets (Structural Rivet) should be used.

- For heavy-duty connections (such as supports, photovoltaic mounting brackets), it is recommended to conduct a shear load test or consult the Rivmate engineering team for calculation verification.

The structural rivets of Rivmate have a shear strength of up to 2.5 kN in accordance with the EN ISO 14589 standard, and their long-term fatigue resistance is superior to that of welded connections.

c. Environmental Resistance

The roof is the most vulnerable part in an exposed environment. Ultraviolet rays, moisture, acid rain and salt fog will continuously erode the fasteners. If the anti-corrosion performance is insufficient, the rivet points may rust through within a few years, leading to water seepage and even structural failure.

- Coastal / High Humidity Environment → Select Closed-End Stainless Rivet, which is resistant to salt fog and rust.

- Industrial Area / Acid Rain Environment → Recommend Nickel Coated or Copper Core Rivets, with strong resistance to chemical corrosion.

- Extremely Temperature Differential Climate → Choose EPDM Gasket Combined with Closed-End Rivets, capable of withstanding a temperature range of -40°C to 120°C.

- General Roofing → Aluminum alloy rivets can meet the daily rust prevention requirements, offering both light weight and economy.

The anti-corrosion products of Rivmate passed the ASTM B117 salt spray test for 1000 hours without rust, ensuring that the roof system can have a corrosion protection lifespan of over 10 years.

d. Appearance and Visual Consistency

For commercial buildings, public facilities and residential projects, the roof not only serves as a protective system but also constitutes a visual component of the building facade. Incongruous appearance of the connection pieces will undermine the overall architectural design sense.

- Choose Color-Coated Rivets, with the color matching that of the roof panel, to enhance the overall aesthetic appeal.

- It is recommended to use UV-stabilized polyester coating to prevent powdering or fading after prolonged exposure to sunlight.

- For metal curtain walls and decorative roofs, the sealed dome structure can be selected, with a smooth and flat cap surface, providing a more unified visual effect.

- Rivmate offers RAL standard color customization service to meet architects’ requirements for visual consistency.

Comprehensive Suggestions

| Selection Criteria | Recommended Rivet Type | Suggested Material Combination | Typical Application |

|---|---|---|---|

| Material Compatibility | Sealed / Aluminum Alloy | Aluminum + Aluminum / Aluminum + Stainless Steel Mandrel | Aluminum roofing panel joints |

| Load-Bearing Strength | Structural Type | Stainless Steel + Stainless Steel | Support structures, high wind pressure zones |

| Environmental Durability | Sealed Type | Stainless Steel + EPDM Washer | Coastal areas, acid rain environments |

| Aesthetic Consistency | Color-Coated Dome Type | Aluminum + Painted Coating | Commercial buildings, architectural façades |

FAQs: Blind Rivets for Roofing

Q1: Why are blind rivets used instead of self-tapping screws for the roof?

A: The greatest advantage of blind rivets lies in their one-sided installation, waterproof sealing, and structural stability. Self-tapping screws rely on torque to compress the washers. If the installation angle or torque is uneven, it can cause water seepage through tiny cracks. Blind rivets achieve a permanent seal through the plastic expansion of the cap body and the locking of the core shaft, and are not affected by torque errors.

Furthermore, the riveted structure has better vibration resistance than the screws, making it more suitable for structures like metal roofs that are frequently subjected to wind loads. During the long-term maintenance period, the leakage rate of the blind rivets can be more than 40% lower than that of the screws.

Q2: Can sealed-type rivets really be waterproof?

A: Yes. The closed-type blind rivets have a closed cap design at the tail end. Even if the core shaft breaks, it will not cause a perforation. If combined with an EPDM or neoprene gasket, it can achieve IP67-level waterproof performance.

Rivmate has verified through the ASTM B117 rain simulation test that this structure shows no leakage under continuous water pressure for 120 hours. Therefore, it is widely used in key areas such as roof cover plates, flashing edges, and equipment penetration points.

Q3: Do different metal roofing materials require rivets of different materials?

A: Yes, it must be matched.

There is an electrochemical potential difference between metals. Improper combination can lead to galvanic corrosion. For example, when using aluminum plates with carbon steel rivets, aluminum will rapidly oxidize in a humid environment. The recommended combinations are as follows:

- Aluminum roof panel → Aluminum + Aluminum / Aluminum + Stainless steel core shaft

- Stainless steel roof → Fully stainless steel structure

- Steel roof → Galvanized steel or stainless steel rivets

Q4: How to determine whether the riveting quality is qualified?

A: It can be quickly tested from the following four aspects:

- Hat fit: It should fit perfectly and have no gaps.

- Back expansion condition: It should be evenly symmetrical, without cracks or skewing.

- Core shaft fracture position: The fracture point should be smooth and level with the hat surface.

- Manual inspection: It should not loosen even when slightly twisted, which is considered qualified.

If the cap body is tilted, the core is exposed, or the clamping is not secure, it indicates that the hole diameter or pulling force setting is incorrect. It is recommended to use a calibrated pneumatic or electric riveting gun to maintain consistent core pulling force.

Q5: Which climate conditions are Rivmate rivets suitable for?

A: The roof fastener series of Rivmate covers various climate zones:

- Coastal and salt spray areas → Stainless steel closed type, with corrosion resistance ≥ 1000 hours of salt spray.

- High temperature or cold areas → Aluminum + EPDM sealing gasket combination, capable of withstanding a temperature difference of -40°C to 120°C.

- Industrial polluted environment → Nickel coating or copper core rivets, resistant to acid and alkali gas corrosion.

Each project can be customized for the local climate conditions regarding the type of rivets and the coating scheme.

Conclusion & Rivmate Recommendations

- At the initial stage of selection, factors such as environmental corrosion grade, plate thickness, wind pressure and temperature changes should be comprehensively considered.

- For high-risk areas (ridge, eaves, flashing), closed-type waterproof structures should be given priority.

- Avoid using combinations of different materials (such as aluminum + steel) in humid or coastal areas to prevent galvanic corrosion.

- It is recommended to use electric or pneumatic riveting guns, and regularly calibrate the pulling force to ensure consistency of core breakage.

- For large projects, it is recommended to conduct sample verification and on-site installation tests to ensure compatibility.

Why Choose Rivmate

Full range of products coverage: From closed type, waterproof type to structural type, it meets all the requirements of roof systems.

International Certification: The product has passed the ISO 14589 and ASTM B117 salt spray testing standards.

Professional Model Selection Support: Offers mechanical performance analysis, waterproof rating assessment, and material compatibility consultation.

Fast Delivery and Customized Services: Offers OEM customization, color spraying, and batch production.

Get in Touch with Rivmate

Would you like to know which type of Blind Rivet is the best choice for your roofing project? Rivmate offers professional selection advice and sample testing support for you.

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met