Grip Range for Rivets - The Guide to Choosing Right Grip Range

Table of Contents

During the selection process, the key parameter that determines whether a rivet can be properly formed and securely clamped is its “Grip Range”. In simple terms, the Grip Range represents the total thickness of the material that the rivet can safely and effectively clamp during installation. If the selected Grip Range does not match the thickness of the material, even if the rivet itself is of high quality, it may still result in problems such as insufficient clamping, deformation of the cap body, or fracture of the core shaft. Correctly understanding and calculating the grip range for rivets is the prerequisite for every assembly engineer to ensure the connection strength and waterproof performance.

This blog will systematically explain “how to measure grip range”, “how to select the appropriate clamping range”, and the structural details that should be noted in different applications through technical examples and standard data tables (rivets grip length chart).

What Is the Grip Range of a Rivet?

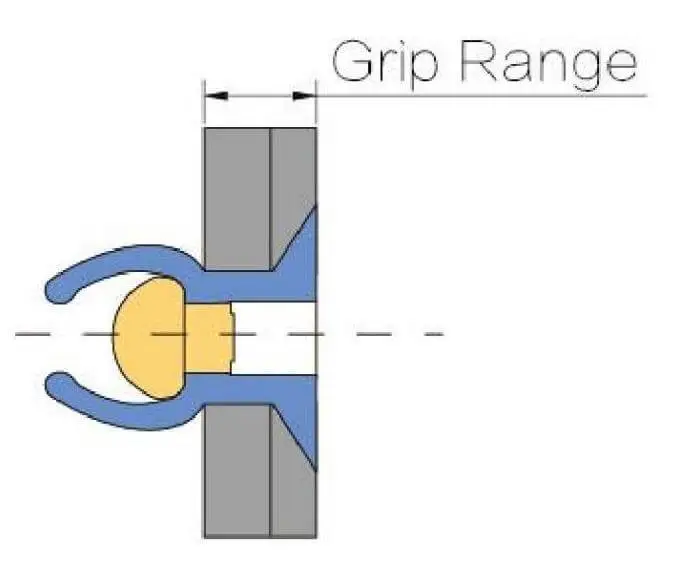

In the field of riveting engineering, the Grip Range is one of the most fundamental and crucial parameters. It refers to the total thickness range of the materials through which the rivet can reliably clamp and form a secure connection during installation. In other words, when the total thickness of the two or more layers of materials being connected falls within this range, the rivet can expand, lock, and achieve the designed strength normally.

The Grip Range is usually indicated in millimeters (mm) or inches (inch), for example, 3.2–4.8 mm or 1/8”–3/16”. This range indicates that if the total thickness of your material is between 3.2 and 4.8 millimeters, this type of rivet can be safely used without being too tight or deformed excessively. Choosing the correct Grip Range means that the plastic expansion, core shaft fracture and cap fitting during the riveting process can all be in the best condition.

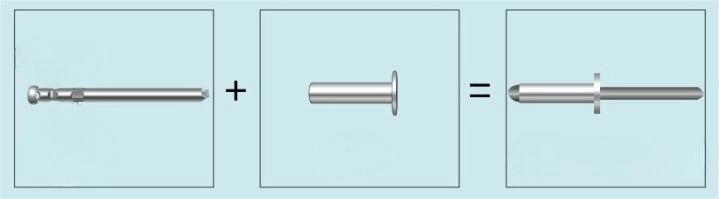

Grip Range ≠ Rivet Length

- Rivet Length (Total Length of Rivet) refers to the overall length of the rivet from the cap edge to the tail end;

- Grip Range (Clamping Range) is the thickness of the material that it can effectively grip.

The two are closely related but not identical. The total length of the rivet affects “the remaining space after installation” and “the back expansion form”, while the Grip Range determines whether the rivet can fully lock the material. For example, for a 4.8×12 mm rivet, its Grip Range might be 3.0–6.0 mm. Beyond this range, it cannot ensure sufficient expansion or stable locking force.

In professional assembly, the selection of the Grip Range is often more important than the total length, as it directly affects the connection quality, waterproof performance and structural safety. If the material thickness is unstable (such as with coatings, sealing gaskets or paint layers), Rivmate engineers usually recommend leaving a margin of 0.2–0.3 mm to prevent insufficient clamping due to assembly tolerances.

Working Principle of Grip Range

When the rivet is inserted into the hole, the riveting gun pulls the core shaft. The conical end at the tail of the core shaft pushes the tail of the rivet cap body outward to expand, thereby forming a “mushroom-shaped” or “umbrella-shaped” structure on the back. At this point:

- If the material thickness is lower than the lower limit of the Grip Range, the rivet will fail to provide effective back support, resulting in loosening;

- If the material thickness is higher than the upper limit of the Grip Range, the core shaft cannot fully break or the cap body will be subjected to abnormal force, leading to poor riveting.

The grip range can be understood as the “safe working range” that the nail designer has set for this specification. Any nailing operation outside this range is considered a potentially risky operation.

Why Grip Range Matters

In the selection of rivets, the Grip Range is a crucial parameter that determines the reliability and service life of the connection. It may seem like a simple thickness range, but it directly affects whether the rivet can form a correct locking structure.

① Structural Integrity

The Grip Range directly affects the “back expansion shape” of the rivet and the “locking position of the core shaft”. Under standard conditions, the tail end of the rivet will form a “mushroom-shaped” expansion on the material’s back, achieving a secure clamping. However, if the Grip Range is improperly selected, the structural strength will significantly decrease.

- Grip Range too small → The nails cannot fully fill the hole walls, and the cap expands prematurely. The result is insecure clamping, vibration-induced loosening, and uneven force distribution on the back.

- Excessive Grip Range → Before the core shaft breaks, the expansion is not complete, resulting in a “false lock”. The rivets seem to be installed properly, but in fact, the interior has not been fully formed.

A deviation of the Grip Range of only ±0.5 mm would result in a decrease of approximately 18% in the average tensile strength and 12% in the shear strength. For high-stress areas, such as roof supports or steel truss connections, this difference is sufficient to affect the overall safety factor.

② Waterproofness and Sealing Capability

In the application of Blind Rivet (blind rivets), the Grip Range not only affects the mechanical strength but also determines the sealing quality. An appropriate Grip Range enables the rivet head to closely adhere to the material surface, forming a stable waterproof barrier.

Especially in roof systems, exterior wall panels, and waterproof and thermal insulation boards, the correct matching of Grip Range is the foundation for reliable waterproofing. According to Rivmate’s long-term project data, when waterproof closed-end rivets are installed in Grip Range in a value-based manner, their sealing lifespan is approximately 30-40% longer than when installed at the limit value.

③ Assembly Efficiency and Process Stability

In mass production or on-site assembly, the precise matching of Grip Range can significantly enhance efficiency and consistency. For automated production lines, the precise control provided by Grip Range enables stable equipment tension output and reduces the rate of defective products.

Measurement Method

The most common and reliable method is to use a vernier caliper or a thickness gauge. When measuring, the following principles should be followed:

- Measure the total thickness of all clamping layers, including the sheet material, gaskets, coatings, sealing films, etc.

- If there are local coatings or anti-corrosion layers, add a correction value of 0.2–0.3 mm based on the thickness.

- For composite materials (such as aluminum + plastic), measure the actual pressed thickness instead of the loose superimposed value.

Grip Range Matching Principle

The total thickness of the material measured must fall within the middle value range of the specified Grip Range of the rivets. It is strictly forbidden to choose the specifications at the extreme values of the range. For example: If the material thickness is 2.8 mm, a rivet with a Grip Range of 1.0–4.0 mm can be selected. If the thickness is 4.5 mm, a specification of 3.0–6.0 mm should be chosen instead of the critical one.

The median value of Grip Range represents the most ideal working range for the forming force of the rivet, the expansion shape and the fracture point of the mandrel. If it is used continuously at the upper or lower limit, it will lead to stress concentration, warping of the cap body or loosening of the rivet point.

Experience Formula (Recommended by Rivmate):

Ideal material thickness ≈ Lower limit of Grip Range + 70% × (Upper limit of Grip Range – Lower limit of Grip Range)

Installation Allowance

In actual assembly, the materials are often not perfectly uniform. Taking into account tolerances, coatings, temperature expansion and gasket compression, appropriate margins should be reserved.

Coating or painted parts: Increase by 0.2–0.3 mm.

Add gaskets or rubber seals: Increase by 0.5 mm.

The high-temperature assembly scenarios (such as aluminum parts) can be slightly reduced to prevent thermal expansion.

Grip Range Reference Table : Grip Range vs Material Thickness

This table shows the typical Grip Range corresponding to different bolt diameters. As the diameter increases, the Grip Range also expands to accommodate thicker or multi-layered structures. However, it should be noted that as the Grip Range expands, the required pulling force also increases, and the installation tools must have the corresponding load capacity.

| Rivet Diameter | Grip Range | Recommended Total Thickness |

|---|---|---|

| 3.2 mm | 0.8–3.0 mm | 2.0 mm |

| 4.0 mm | 1.0–4.0 mm | 3.0 mm |

| 4.8 mm | 3.0–6.0 mm | 5.0 mm |

| 6.4 mm | 4.0–8.0 mm | 6.0 mm |

Grip Range by Rivet Type

| Rivet Type | Grip Range Characteristics | Typical Applications |

|---|---|---|

| Open-End Rivet | Narrow grip range; requires precise matching to material thickness. Suitable for lightweight structures and single-sheet connections. | Thin sheet assemblies, home appliances, light industrial products |

| Closed-End Rivet | Moderate grip range with superior waterproof sealing performance; mandrel is completely enclosed inside the rivet body. | Roofing systems, exterior wall panels, electrical enclosures |

| Multi-Grip Rivet | Wide grip range—can cover up to three times the normal thickness variation; highly adaptable but with slightly lower peak strength. | OEM production lines, mixed-thickness assembly, maintenance and replacement applications |

| Structural Rivet | High-strength grip design with large expansion range; mandrel lock system provides excellent tensile and shear resistance. | Steel structures, solar mounting systems, load-bearing connections |

This is the most common blind riveting structure. Its Grip Range is relatively narrow, typically covering a thickness range of 2–3 mm. After installation, the core shaft part breaks and remains inside the opening, forming the basic clamping force. These rivets have high requirements for hole diameter accuracy and the installation angle must be perpendicular; otherwise, it is prone to cause the cap body to warp or insufficient clamping.

It is applicable for lightweight thin plate assembly or situations with controllable thickness.

If the material thickness fluctuates greatly, the Multi-Grip series should be used instead to avoid not being able to grip tightly.

The tail end of the closed-type rivet is sealed, and it does not penetrate even after the core shaft breaks. It has excellent waterproof and gas-sealing performance. Due to the limited internal closed space, the median value in Grip Range is relatively small, usually ranging from 2 to 4 mm. These rivets are often used in structures with strict requirements for sealing, such as roof systems, exterior wall panels, and electronic equipment enclosures.

- When selecting the model, it is necessary to ensure that the material thickness is close to the median value in the Grip Range to guarantee reliable sealing.

- If additional sealing is required, EPDM gaskets can be used in combination.

- It is suitable for applications that need long-term corrosion protection or exposure to humid environments.

The multi-grip type rivets are designed with a special cap body geometry and core shaft structure, enabling them to adapt to a wider range of material thicknesses. For instance, a single model can cover thicknesses of 3–9 mm, which is 2 to 3 times more adaptable than ordinary rivets. These rivets are highly suitable for mixed-size production or repair replacement purposes, reducing the number of inventory models and enhancing assembly flexibility. However, it should be noted that their internal expansion path is longer, so the maximum tensile strength is often slightly lower than that of a single Grip specification rivet.

- Suitable for OEM production lines with significant differences in plate thickness.

- If the load-bearing capacity of the connection area is high, structural rivets should be preferred.

- When choosing, attention should be paid to the consistency of production batches to avoid differences in mechanical properties.

The structural rivets adopt a mechanical lock core design, and even if the core shaft breaks, it is still locked by the cap body, thus maintaining the overall force state. Its Grip Range is relatively large, and the expansion is uniform, making it suitable for thick plates, multi-layer structures or high-load applications. This type of rivets is commonly used in building steel structures, photovoltaic supports and industrial equipment.

- Suitable for engineering structures with high requirements for strength, seismic resistance and vibration resistance.

- Installation requires the use of professional riveting equipment to ensure the accuracy of the core separation position.

- In environments with high wind pressure or heavy loads, it can effectively replace traditional welding or bolt connections.

Choose the Right Grip Range with Rivmate

In the field of blind riveting, Grip Range is not merely a parameter, but rather a core indicator of connection reliability. It determines whether the rivets can form an ideal expansion shape during installation, achieve uniform clamping force, and maintain long-term structural stability.

Rivmate Testing and Support

All Rivmate series fasteners have been verified in accordance with the following international standards:

- ISO 14589 (Performance Test for Riveted Connections)

- ASTM B117 (Salt Spray Corrosion Test)

- DIN 7337 (General Specification for Blind Rivets)

The Grip Range of each product has undergone dual tests of mechanics and environment to ensure stable and reliable performance during actual assembly. Rivmate can also provide customers with clamping force analysis reports, trial riveting verification, and structural calculation services, helping engineers verify the rationality of the design in advance.

Want to know how to select the right Grip Range for your project? Contact the Rivmate technical team immediately to obtain professional selection guidance and sample testing support.

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met