When to Use Rivets?

Table of Contents

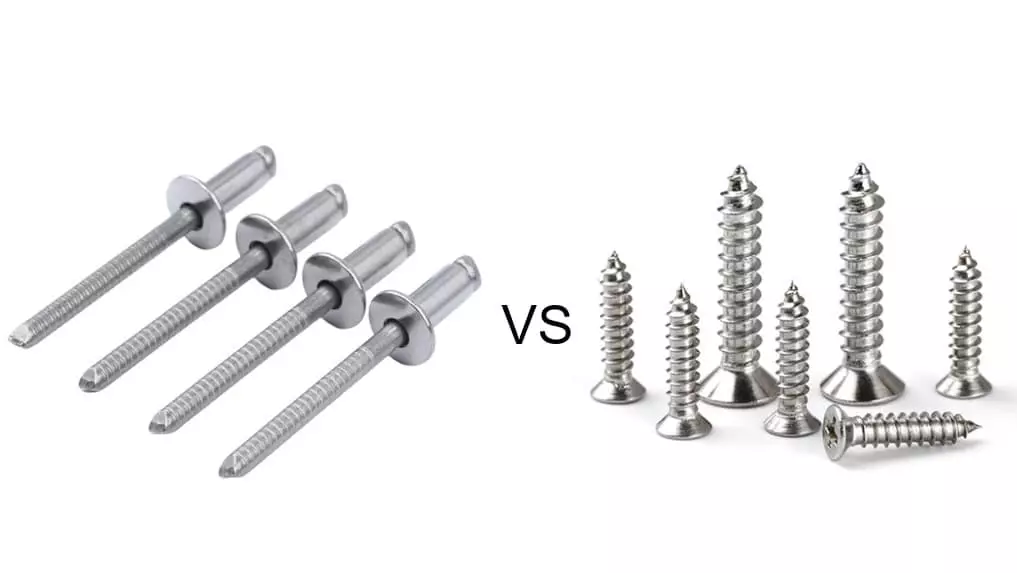

During the product design and assembly process, the choice of the appropriate connection method directly affects the strength, cost and lifespan of the structure. Rivets, as a traditional yet efficient means of fastening, are still widely used in various industries. However, when faced with multiple alternative solutions such as screws, welding, and gluing, many engineers will ask: “When to Use Rivets?”

This issue not only involves technical judgment, but also relates to manufacturing efficiency, material compatibility and long-term reliability. Understanding the advantages and applicable scenarios of rivets can help engineers make better decisions at the initial design stage, avoiding rework, failure or unnecessary cost waste.

Permanent Joint

After assembly, the rivets will undergo irreversible plastic deformation. Compared to screws, they are less likely to loosen due to vibration or prolonged use. Especially in critical load-bearing structures, rivets can ensure long-term stability and safety.

Blind Installation

The rivets can be installed on one side, which is an advantage that cannot be matched by screws and welding. For structures that are narrow and cannot be contacted on both sides, blind rivets are the ideal choice. For example, in the assembly of car body interiors or electronic enclosures, rivets can effectively simplify the process.

Vibration and Fatigue Resistance

Bolts possess excellent vibration resistance and fatigue resistance properties. The reason why bolts are widely used in the aviation, automotive and railway industries is that they can maintain stable connections even under high-frequency vibrations and alternating loads. Research has shown that bolted structures often outperform welded components in terms of fatigue life.

Lightweight and High Strength-to-Weight Ratio

Lightweight materials such as aluminum alloys and titanium alloys can fully utilize their strength advantages during riveting without experiencing performance degradation due to high-temperature welding. This makes rivets particularly suitable for the aerospace and electric vehicle industries, allowing for enhanced strength while reducing the overall weight.

When Must Rivets Be Used Instead of Screws or Welding?

In mechanical manufacturing, automobiles, aerospace, and construction, the choice of fastening method is of great significance. Screws, rivets, and welding each have their own advantages. However, in some specific situations, rivets are the best choice.

1. One-Side Access → Blind Rivets

When the structure can only be installed from one side, screws and welding cannot complete the operation.

Blind rivets can achieve efficient connection on a single side.

This kind of situation is commonly seen in scenarios such as aircraft skins and the inner cavities of car doors.

2. High Vibration Conditions → Better Loosening Resistance

Nuts are prone to loosening under prolonged vibration. Even with the use of anti-loosening washers or thread sealants, it is difficult to completely prevent this from happening. The rivets are of a permanent mechanical locking type and have better vibration resistance than screws.

The data shows that in the aviation industry, more than 60% of structural connections use rivets instead of screws, precisely because of their superior fatigue resistance and anti-loosening properties.

3. Thin Sheet Metal / Composites → Avoid Thread Damage

The screw requires sufficient plate thickness to form a reliable thread.

For thin metal plates or composite materials, screws are prone to slip or break.

The rivets are fixed by deformation through riveting and do not rely on threads. Therefore, they are more suitable for thin-walled materials.

4. Appearance & Aerodynamics → Countersunk Rivets

In automotive body parts, aircraft wings or high-speed rail car bodies, surface flatness and aerodynamic performance are of great importance.

The countersunk rivets can be flush with the surface of the material, reducing air resistance while maintaining a good appearance.

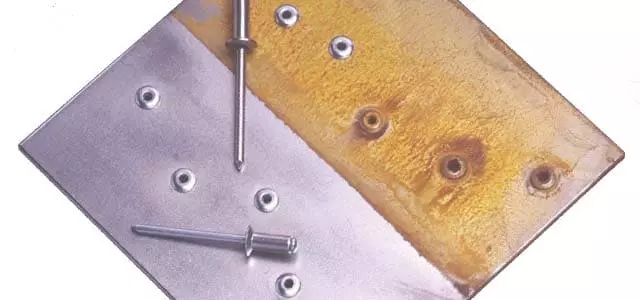

5. Welding Not Feasible → Riveting as an Alternative

Welding generates high temperatures, which may lead to:

- The strength of the heat affected zone (HAZ) decreases

- Material deformation

- Failure of the coating or anti-corrosion layer

For high-strength alloys or heat-sensitive materials, riveting is a better option. In aircraft manufacturing, more than 70% of the aluminum alloy components are joined by riveting rather than welding, and this is for this reason.

- Can only be operated on one side → Use blind rivets

- High vibration conditions → Rivets are more reliable than screws

- Thin plates or composite materials → Avoid thread damage

- Requirements for appearance/airflow → Choose counter-sunk rivets

- Welding is not feasible → Riveting is an alternative solution

Bolts are not only a traditional technique, but also the only reliable connection method under specific working conditions.

Rivets Compared with Other Fastening Methods

| Fastening Method | Key Advantages | Limitations | Best Use Cases |

| Rivets | Permanent, vibration-resistant, blind installation | Not removable | Aerospace, automotive, thin sheet metal |

| Screws | Removable, easy to install | Can loosen under vibration | Electronics, furniture, repair parts |

| Welding | Strong, continuous joints | Heat distortion, requires skilled labor | Heavy structures, pipelines |

| Adhesives | Smooth surface, distributes load | Long curing time, weaker in shear | Composites, decorative panels |

Comparison of Characteristics

- Nails: Permanent connection. Once installed, they cannot be easily removed.

- Screws: Removable. Suitable for areas that require frequent maintenance and replacement.

Analysis of Advantages and Disadvantages

- The rivets have stronger vibration resistance. They are less likely to loosen under long-term vibration.

- Screws may fail under high-frequency vibration, even with anti-loosening measures in place, and there is still a risk.

- Screws are prone to damaging the threads in thin plates or composite materials. Rivets are more stable in such materials.

If you want maintainability → Choose screws.

If you need good vibration resistance and long-term stability → choose rivets.

Comparison of Characteristics

- Nails: Cold connection, no heating required.

- Welding: High-temperature operation, may affect material properties.

Analysis of Advantages and Disadvantages

- Welding will create a heat affected zone (HAZ), resulting in reduced strength or structural deformation.

- Rivets avoid thermal stress and are suitable for heat-sensitive alloys and composite materials.

- Welding offers good overall sealing performance, but the process is complex and the quality consistency depends on the skill level of the welder.

- Rivet connections do not require special environments and have more stable assembly cycle times.

If the material can withstand high temperatures and requires complete sealing → Choose welding.

If there is concern about heat effects or connection between different materials → choose rivets.

3) Rivets vs Adhesives

Comparison of Characteristics

- Nails: Mechanical connection, they can bear weight immediately after installation.

- Adhesives: Chemical connection, they require a curing time.

Analysis of Advantages and Disadvantages

- Adhesives are widely used in composite materials and sealing applications, but the curing conditions (time, temperature, humidity) affect reliability.

- Nails can be installed immediately without waiting.

- Adhesives have limited shear strength and may fail due to long-term aging.

- Nails have clear load-bearing capacity and more predictable fatigue resistance.

If lightweighting and sealing performance are the priorities → Adhesives can be used.

If one seeks immediate effectiveness and long-term stability → The rivet is superior.

Common Applications: When to Use Rivets

A rivet is a widely used permanent fastener. In many situations, screws or welding are not suitable, and rivets become the best choice. Here are some typical industry rivet application scenarios:

1) Aerospace Industry → Skin Panels and Fatigue Resistance

In aerospace engineering, the answer to “when to use rivets” is very clear. A large number of rivets are used in the aircraft skin, wing frame and cabin section connections.

The reasons include:

- In a high-vibration environment, the rivets are less likely to loosen.

- The aluminum alloy material is sensitive to welding, and riveting avoids damage to the heat affected zone.

- The arrangement of rivets can disperse the load and increase the fatigue life.

A modern commercial aircraft may contain more than 2 million rivets.

2) Automotive Industry → Body Panels and Chassis Components

In automobile manufacturing, rivets are commonly used for:

- Body panels, such as doors, roof, and trunk lid.

- Attachment of chassis components, such as heat shielding plates and reinforcement plates.

Advantages:

- The process is quick. Assembly can be completed with a riveting gun.

- It is reliable in a vibrating environment. It is more durable than screws.

- It is suitable for connecting different materials, such as aluminum plates and steel plates.

With the trend towards lightweighting, aluminum alloy bodies are becoming increasingly popular. The welding process is difficult, while riveting has become a more economical alternative method.

3) Construction and Architecture → Curtain Walls and Roofing

In the construction industry, when to use rivets is commonly found in:

- Fixing of aluminum alloy curtain wall keels and panels.

- Jointing of metal roof panels.

Advantages:

- Strong wind resistance capacity.

- Quick installation, suitable for large-scale construction.

- The rivets have a neat appearance and can be coordinated with the coating.

4) Electronics and Home Appliances → Thin Sheet Assembly

In electronic products and household appliances, rivets are used for:

- The thin plate shell is fixed.

- The internal support is connected to the heat dissipation component.

Reason:

- Screws are prone to damaging thin plates, while rivets are more reliable.

- The assembly process is highly automated, making it suitable for mass production.

- The rivet heads are small, which does not affect the appearance.

5) Furniture & DIY → Fast and Permanent Assembly

In furniture, hardware and DIY applications, rivets are commonly found in:In furniture, hardware and DIY applications, rivets are commonly found in:

- Metal frame furniture.

- Toolboxes, storage cabinets.

- DIY projects require quick and maintenance-free connection points.

Advantages:

- The tool is simple and easy to install.

- No professional welding equipment is required.

- The cost is low and it is suitable for small-scale production or individual use.

Key Factors Affecting Rivet Selection

In engineering and manufacturing, choosing the appropriate rivets is of utmost importance. Different working conditions determine different selection strategies. The following factors are the core for determining “when to use rivets” and how to select them.

a. Material Type and Thickness

- Aluminum alloy: Lightweight, suitable for aviation and automobiles. Moderate in strength, but good in corrosion resistance.

- Stainless steel: High in strength, resistant to corrosion. Commonly used in construction and ships.

- Steel: Low cost, strong in bearing capacity. Suitable for general machinery.

- Composite materials: Not suitable for threaded connections. Rivets can disperse stress and avoid inter-layer damage.

Thickness is also crucial. Thin plates (≤1.5mm) are prone to being pulled through and require large flange heads or back washers. Thick plates can withstand higher shear and tensile loads.

b. Load Type (Shear vs Tensile vs Fatigue)

- Shear Load: Rivets are best suited for withstanding shear force. The hole wall is compressed, ensuring a stable connection.

- Tensile Load: The diameter or quantity of the rivets should be increased. Otherwise, they may be easily pulled out.

- Fatigue Load: Common in the aviation and rail industries. High-quality hole processing and proper arrangement are required.

Empirical data: In the aviation industry, more than 70% of rivet operations are carried out in a shearing state, rather than a stretching state.

c. Environmental Conditions

- High Temperature: Avoid using aluminum rivets as their strength significantly decreases at high temperatures.

- Damp Environment: It is recommended to use stainless steel or rivets with anti-corrosion coatings.

- Corrosive Environment: Consider electrochemical corrosion. Contact between different metals will accelerate damage.

In the fields of marine engineering and chemical industry, choosing the appropriate materials and coatings is particularly crucial.

d. Appearance and Surface Treatment

- Countersunk Head Rivets: Suitable for applications with high requirements for appearance and aerodynamics (such as aircraft skins and body panels).

- Blind Rivets: Prevent leakage and ensure a complete surface.

- Surface Coatings: Can enhance appearance and corrosion resistance.

In the consumer electronics and home appliance industries, the appearance quality directly affects the user experience.

Rivmate Material and Coating Options

Rivmate offers a variety of materials and coatings to meet different working conditions:

- Aluminum, stainless steel, carbon steel → Covering from lightweight to high-strength requirements.

- Anti-corrosion coatings → Including galvanization, nickel plating, anodizing, etc.

- Weather-resistant solutions → For humid, marine and chemical environments.

By combining materials and coatings, Rivmate can assist customers in balancing cost, strength and durability.

Rivmate Expert Advice: How to Select the Right Rivet

The selection of rivets is not simply a matter of size matching. Different materials, loads and working conditions all have specific requirements for diameter, clamping range and head shape. The engineering team at Rivmate has summarized the following suggestions to help customers avoid common mistakes and enhance connection reliability.

Select the Right Diameter, Grip Range, and Head Style

- Diameter: Determines the load-bearing capacity. A common rule of thumb is that the diameter of the rivet is approximately three times the thickness of the sheet.

- Grip Range: Must cover the actual layer thickness. Too small will cause the sheet to be pulled through, and too large will not allow for secure locking.

Round head → Universal, easy to install.

Large flange head → Suitable for thin sheets or soft materials, reducing surface pressure.

Countersunk head → Suitable for occasions with high requirements for appearance or air power.

Avoid the Common Mistake: Ignoring Material Compatibility

Many users only focus on the size of the rivets while neglecting the material properties, which often leads to early failure:

- Electrochemical Corrosion: Different metals coming into contact (such as aluminum and stainless steel) will corrode rapidly in a humid environment.

- Strength Mismatch: Using a high-strength base material with a low-strength rivet may fail under fatigue.

- Insufficient Environmental Adaptability: In marine or chemical environments, without a protective coating, the lifespan will be significantly shortened.

Solution:

- Keep the base material similar to the rivet material.

- If necessary, choose rivets with anti-corrosion coatings.

- Conduct salt spray or fatigue tests under critical operating conditions.

Rivmate Engineering Support

Rivmate offers comprehensive engineering support to ensure that customers make the right decisions:

- Consulting Services: Based on the design drawings and operating conditions, recommend the optimal riveting solution.

- Sample Testing: Samples can be provided for actual assembly and tensile/shear tests.

- Technical Documentation: Includes material compatibility tables, installation specifications, and failure analysis guidance.

FAQ

- Under high vibration and fatigue conditions, rivets are usually more reliable than screws.

- Screws rely on preload and friction and are prone to failure due to loosening or vibration.

- Rivets are of permanent mechanical locking type and have no rotating interface, so they will not loosen by themselves.

In aircraft structures, over 60% of the connection points use rivets, and the reason for this is that they offer better resistance to fatigue and loosening.

2) Can Blind Rivets Be Used in Plastics or Composites?

Yes, but it requires the correct selection of the model.

- For soft materials or composite materials, a large flange head or a back washer should be selected to distribute the surface pressure.

- Using closed-end blind rivets can prevent the core shaft from loosening and causing damage to the material.

- In high-load situations, it is recommended to conduct actual tests to confirm the strength and fatigue performance at the edge of the hole.

- Ordinary open-type rivets are not waterproof. Water may seep through the pores and crack locations.

- If waterproofing is required, sealed/closed-end rivets should be chosen and sealed with sealant during assembly.

- In the aviation and automotive industries, sealing rivets are commonly used to ensure the sealing performance of compartments and the body.

4) How to Prevent Rivet Corrosion?

- Material Matching: Try to use materials with similar electrical potential to the base material. For example, use aluminum rivets for aluminum plates.

- Protective Coatings: Use galvanized, nickel-plated or anodized rivets to enhance corrosion resistance.

- Isolation Measures: Add coatings, sealants or gaskets between different metals to reduce galvanic corrosion.

- Environmental Selection: In marine or chemical environments, it is recommended to use stainless steel or special anti-corrosion rivets.

Rivmate Solution: Offers a variety of material and coating combinations, such as stainless steel closed-end blind rivets + anti-corrosion coating, which is suitable for high humidity or salt spray environments.

Conclusion: When to Use Rivets as the Best Choice

In industrial manufacturing, screws, welding and adhesives all have their application scenarios. However, under the following conditions, Rivets (bolts) are often the best choice:

- Permanent connection → One-time installation, long-term reliability.

- High-vibration environment → Better anti-loosening performance than screws.

- Single-sided operation → Blind rivets provide the only feasible solution.

- Thin plates or composite materials → Avoid thread damage, maintain structural integrity.

- Welding not feasible → No heat affected zone, does not damage material properties.

Why Choose Rivmate?

Rivmate not only offers a full range of rivet products (blind rivets, structural rivets, countersunk rivets, waterproof rivets, etc.), but also provides:

- Engineering Selection Guidance: Based on materials, loads and environment, recommend the best solution.

- Samples and Testing Support: Assist customers in verifying connection strength and lifespan.

- Technical Documents and Standards: Ensure that the installation process is controllable and traceable.

This combination of “product + engineering support” ensures that customers not only can purchase the appropriate rivets, but also can achieve long-term reliability in their applications.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met