Do Zinc Plated Rivets Rust?

Table of Contents

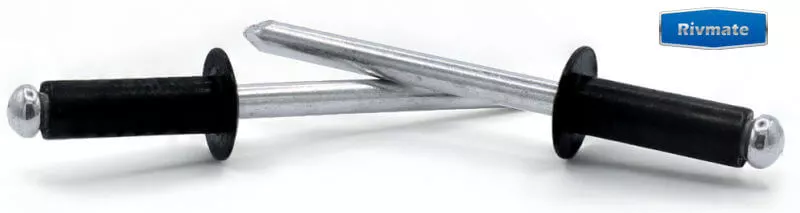

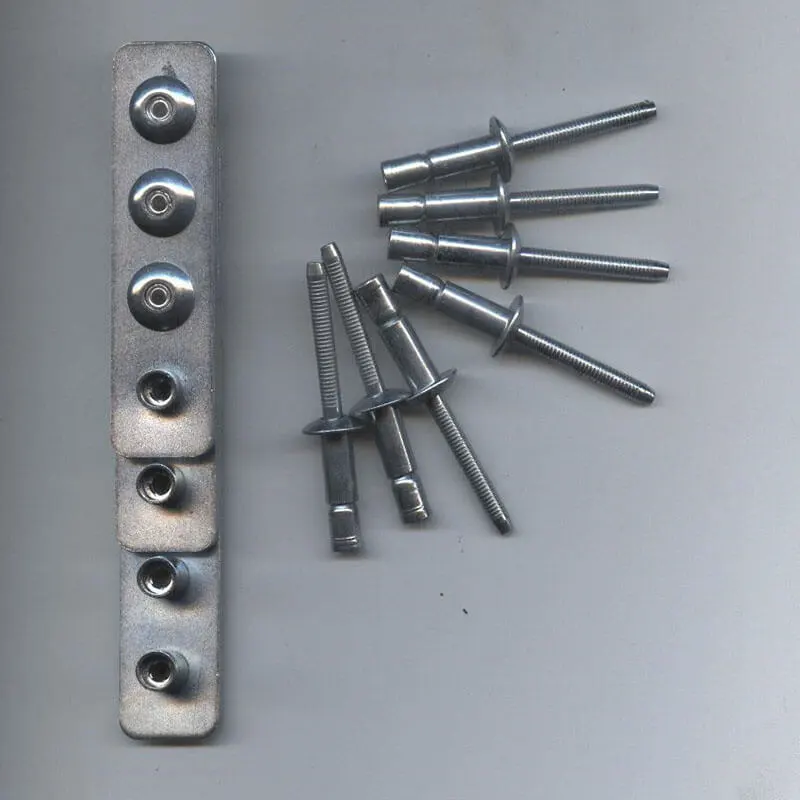

zinc plated is a common finish for blind rivets. Its purpose is to increase the corrosion resistance of the rivet. So do zinc plated rivets rust?

Through this post you will learn the reasons why zinc plated is used for blind rivets, possible failures and how to extend the life.

The importance of rivets in structural connections

Rivets play a key role in structural connections as a permanent joint. The use of rivets in high-load, long-term stress or vibration environments is an excellent choice. They do not rely on threading or welding and can achieve a high strength bond between different materials. Therefore, they are widely used in transportation, machinery and equipment, and steel construction.

Compared to traditional bolting or welding processes, rivets offer the advantages of ease of installation, vibration resistance and adaptability. The efficiency and reliability of rivets is even more evident if your riveting application is in a thin plate, single-sided operation or automated production environment. Therefore, rivets continue to be an indispensable fastening solution for structures with high demands on connection quality and long-term stability.

Purpose of zinc plating as a common anti-corrosion treatment for rivets

Zinc Plating is one of the most common anti-corrosion surface treatments for rivets. Its main purpose is to form a dense layer of zinc on the surface of the rivet substrate, through the “sacrificial anode” principle to resist the environment of moisture, oxygen and corrosive media on the metal body erosion, thereby extending the service life of the product.

The main purposes of zinc plating are as follows:

- Corrosion protection: The zinc layer is oxidized first through the “sacrificial anode” effect, protecting the rivet body (usually carbon steel) from rust and corrosion.

- Extend service life: Reduce the corrosion rate of rivets in humid, salt spray, weak acid and alkali environments to extend the durability of structural connections.

- Improved appearance: The zinc layer can provide a bright or colored appearance, enhancing the visual consistency and identification of the product.

- Facilitates Subsequent Processing: Electroplated zinc layers can be used as a primer to facilitate the adhesion of paint, passivation or sealer coatings.

what is rivets zinc plating?

Zinc Plating of rivets is a surface treatment process in which a thin layer of metallic zinc is plated onto the surface of the rivet. The purpose of this process is to enhance the corrosion resistance and service life of the rivet. This process is widely used for carbon steel rivets and is one of the most common anti-corrosion treatments used in industrial fasteners today.

✅ Process Principle

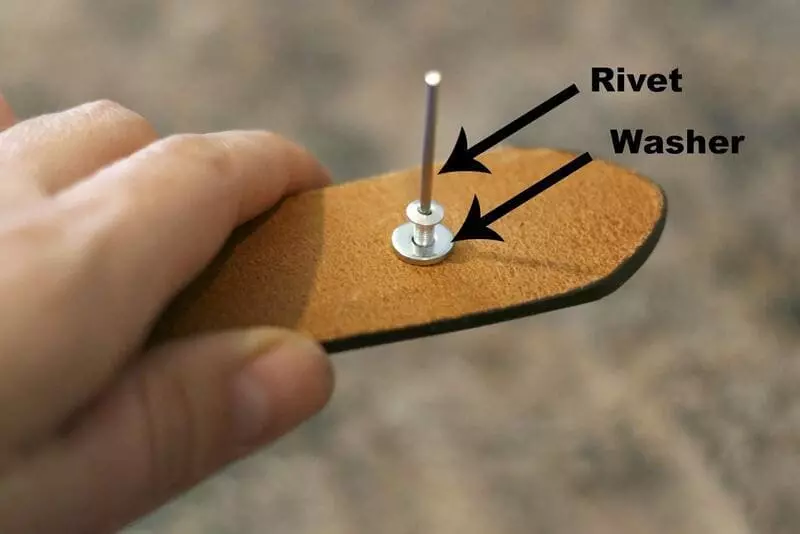

Zinc plating deposits zinc ions on the surface of rivets through an electrolytic process, forming a dense zinc layer with a thickness of approximately 5-25 microns. The zinc layer acts as a “sacrificial anode”, which is preferentially oxidized when the rivet is subjected to corrosion, thus protecting the rivet substrate (usually mild steel) from corrosion.

Zinc plating is suitable for low to medium corrosive environments, not for strong acids and alkalis, marine or high salt spray environments. For stronger corrosion protection, Dacromet, hot-dip zinc or stainless steel should be used.

How the zinc layer protects the substrate through the action of a “sacrificial anode”?

⚙️ Explanation of Electrochemical Principles

When the zinc layer on the surface of a rivet is exposed to an environment containing an electrolyte (e.g., moisture, salt spray) with an iron substrate (e.g., mild steel), the two metals form a miniature primary battery system:

- Zinc has a lower potential than iron (more reactive) and is preferentially oxidized in the corrosion reaction, becoming the anode.

- Iron becomes the cathode and is protected by not participating in the oxidation reaction throughout the process.

🛡️ Summary of Protection Mechanisms

- Active Sacrifice: The zinc is corroded first, thus protecting the more valuable or important ferrous substrate materials from rusting.

- Delayed corrosion time: Even if the zinc layer is scratched or partially broken, the surrounding zinc continues to protect the exposed ferrous substrate.

- Non-mechanical barrier: Unlike paints or coatings, zinc layers are electrochemically self-protecting before they fail.

This is why rivets remain rust-free for a longer period of time, even when the zinc layer is locally scratched. It is also an important technical advantage of zinc plating which is widely used in industrial rivets, screws and bolts.

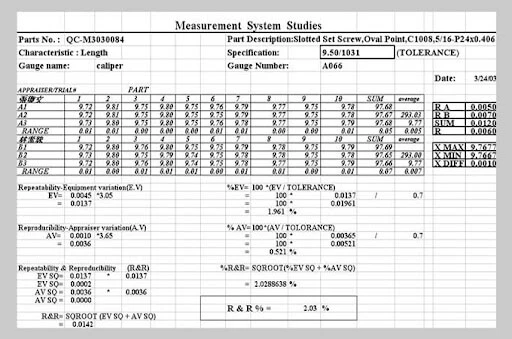

Relationship between rivet plating thickness and corrosion protection lifetime

There is a positive correlation between plating thickness and corrosion protection life. The thicker the coating, the longer the corrosion protection life. However, this relationship is affected by a variety of factors and does not increase linearly.

- The greater the thickness of the zinc layer, the more “sacrificial anode” material is supplied and the longer the protection will last in a corrosive environment.

- Each additional thickness significantly extends salt spray or atmospheric corrosion life in the same environment.

| Zinc Coating Thickness (μm) | Salt Spray Test Duration (ASTM B117) | Typical Protection Life (Neutral Environment) |

|---|---|---|

| 5 μm | 24–72 hours | 6–12 months |

| 8 μm | 72–120 hours | 1–2 years |

| 12 μm | 120–240 hours | 2–3 years |

| 25 μm (thick coating) | ≥ 480 hours | Over 5 years (non-coastal) |

Do Zinc Plated Rivets Rust?

Yes, zinc plated rivets will rust. This is likely to happen when you use galvanized rivets in highly corrosive environments. The zinc coating only provides limited protection for a limited period of time and does not provide “permanent protection” against rust.

Under what conditions does the zinc coating fail?

- High humidity or wet environments (e.g. coastal, tunnels, ship’s hold): water vapor and chlorides accelerate the corrosion reaction of zinc.

- Salt spray or high salt environments: sea breeze, winter salt spreading sections are highly susceptible to rapid corrosion.

- Presence of acidic and alkaline corrosive substances: industrial emissions or cleaning agent residues are prone to damage passivation films.

- Mechanical damage or uneven plating: Scratches, weak areas or damage from riveting processes lead to exposure and localized failure of the zinc layer.

- High temperature environment (> 60°C): the passivation film of the zinc layer of the rivet is unstable and the protection is reduced.

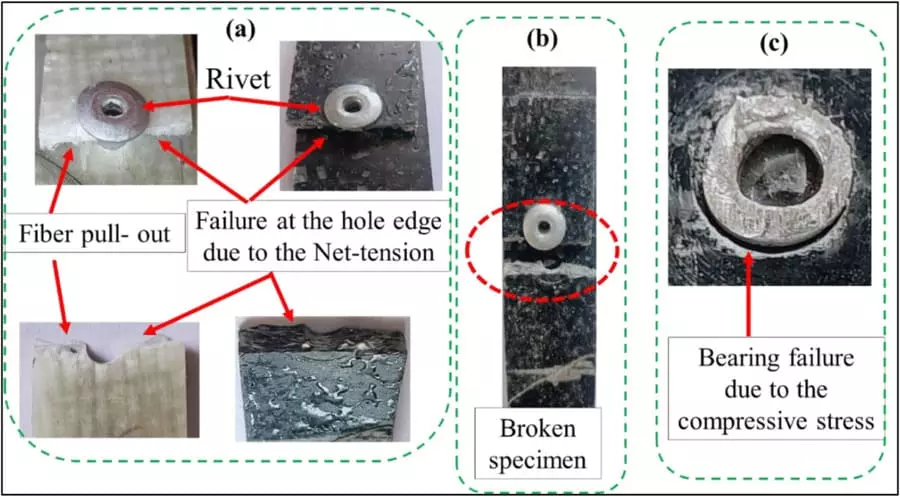

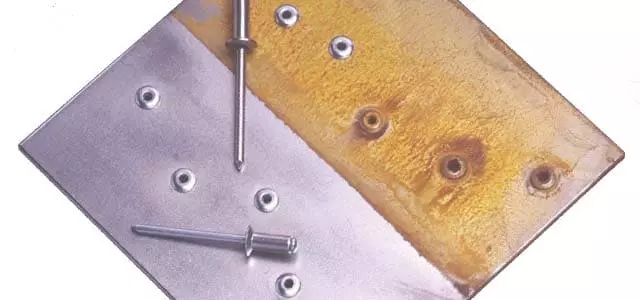

Performance of rivets after failure

White Rust

A powdery substance of zinc oxide and zinc hydroxide generated by the initial corrosion of the zinc layer, with a whitish-gray surface.

Red Rust

Once the zinc layer is completely corroded, the inner layer of carbon steel begins to oxidize, appearing obvious reddish-brown rust spots, structural performance decline.

Coating Spalling, Mottling

The surface passivation film or closure layer flakes off, resulting in localized exposure and rapidly spreading corrosion.

What are the key factors affecting the risk of rivet corrosion?

I. Environmental Factors

Humidity and Water Vapor

High humidity or prolonged dewy environment easily leads to electrolyte formation and accelerates corrosion reaction.

Salt and Chloride

Coastal, salt spray, and high salt spray areas (e.g., winter roads) have significantly higher corrosion rates.

pH Extreme Environments

Acidic (e.g. industrial exhaust fumes) or alkaline (e.g. cleaning agents) can damage the zinc passivation film.

Frequent temperature changes

Large temperature differences tend to form condensation and create microcellular corrosion cycles.

Ⅱ. the rivet itself material and surface treatment

Plating thickness and quality

The thinner the plating or uneven treatment, the more likely to localized failure.

Passivation or closed layer treatment

Lack of passivation (e.g. blue-white zinc / colored zinc) or closed layer of galvanized parts, corrosion resistance time is significantly reduced.

Substrate type

Carbon steel is more susceptible to rust than stainless steel or aluminum and requires higher quality protection.

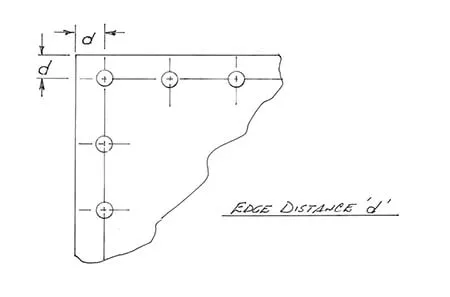

Ⅲ. the structural design and installation mode

Bimetallic contact (galvanic corrosion)

When rivets and connected parts are made of different materials (e.g. aluminum plate + steel nails), the potential difference will accelerate local corrosion.

Gap structure

Tightly fitting pieces or overlapping structures are prone to retain moisture and form crevice corrosion.

Assembly process damage

Riveting process such as zinc layer damage, abrasion or excessive deformation, easy to form a source of corrosion.

Ⅳ. the use of maintenance factors

Long-term unmaintained

No cleaning, no protection, dust and corrosion accumulation will accelerate the damage.

Exposure time is too long

Temporary construction exposure, not timely closed treatment will shorten the service life.

How to extend the life of zinc plated rivets?

Although zinc plated rivets have basic corrosion resistance, their effectiveness is greatly affected by the environment. By improving the quality of plating, structural protection design and construction and maintenance coordination, can significantly improve its corrosion resistance life, to extend the service life of the connection structure.

Method 1. Selection of suitable plating layer and post-treatment process

Improving the corrosion resistance of rivets is first and foremost a matter of optimizing the quality of their surface treatment. By selecting a thicker zinc coating (e.g. ≥ 12 μm), the “sacrificial anode” function can be significantly improved. This enables the zinc coating to withstand corrosion loads for a longer period of time and protects the substrate from erosion. At the same time, the increased thickness of the coating is also effective against the localized effects of mechanical abrasion and stress corrosion.

In addition, passivation and seal coating are key supporting measures. Passivation (e.g. blue-white zinc or colored zinc) forms a stable oxide film on the surface of the zinc layer and reduces the reaction rate of zinc. Seal coatings are an effective secondary line of defense against corrosion in harsh environments by sealing the micropores and cracks on the surface of the plating and preventing the penetration of moisture and electrolytes. Both with the use of rivets in complex environments can significantly enhance the ability to serve.

Method 2. Reasonable selection and structure matching

The selection of rivets should give full consideration to the use of the environment, to avoid the blind selection of low anti-corrosion grade electro-galvanized rivets.

In heavy pollution, high humidity or coastal salt spray environment, should give priority to hot dip galvanized, Dacromet or stainless steel rivets, to reduce the risk of corrosion from the source. Electro-galvanized products are more suitable for indoor, neutral environments and should not be used as a long-term substitute for higher-grade products in structures with well-defined life requirements.

In addition, galvanic coupling corrosion is an important factor affecting the corrosion failure of rivets. When the rivet and the connected material potential difference is large (such as steel nail with aluminum), in the presence of electrolyte will form a microcell, resulting in the anode material (usually rivets) to accelerate corrosion. Selection should try to match the potential close to the combination of materials, or in the interface coated with insulating coatings, inhibit the occurrence of electrochemical corrosion reactions.

Method 3. Installation protection and construction attention

The impact of the construction and installation process on the service life of rivets can not be ignored. Riveting process if the use of improper tools, or operation is not standardized (such as knocking, eccentric force), easy to cause the surface of the zinc layer scratches, cracks or even peeling, the formation of local corrosion source points. Therefore, special installation tools should be used to ensure uniform clamping force and smooth breaking process to protect the integrity of the plating layer.

From a structural point of view, the design should avoid the formation of waterlogged gaps or overlapping structures that are difficult to drain. Because this kind of “sandwich gap” is easy to hide water and moisture, is the high incidence of crevice corrosion and microbial corrosion area. Ventilation and drainage holes should be designed in key areas, or open seams and seals should be used to prevent water vapor retention, thereby enhancing overall durability.

Method 4. Post maintenance and environmental management

Even if the initial selection and construction is reasonable, the later maintenance is still critical to extend the life of the rivets. It is recommended that a regular inspection mechanism be established during use. For outdoor structures or highly corrosive areas, the rivet perimeter should be cleaned regularly to remove salt spray deposits, dust, oil and other contaminants that may accelerate corrosion.

When damage to the zinc layer, the first appearance of white rust or localized red rust spots are found, local repair treatment should be carried out immediately. Such as the use of cold galvanizing spray paint, zinc powder coating, sealant on the defective parts of the cover protection. This “maintenance instead of repair” protection idea can not only slow down the spread of corrosion, but also extend the usable cycle of the structural connection, reducing long-term maintenance costs.

wholesale high quality zinc plated rivets from rivmate

Choosing Rivmate wholesale high quality zinc plated rivets not only means getting quality fasteners with stable performance and consistent appearance, but also guaranteeing the reliability and cost efficiency. It’s a guarantee of reliability and cost efficiency.

Rivmate offers a wide range of standardized zinc plated rivets. Widely used in building hardware, machinery assembly, transportation equipment and other fields. And support bulk purchasing and customization services, is the ideal partner for industrial customers seeking long-term supply security and quality consistency.

Share:

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met