Home » 归档于 eric@world-rivet.com

Top 8 Blind Rivet Manufacturers and Suppliers in Canada

Rivmate Fastener

Top Rivet and Rivet Nut Manufacturer in China

Table of Contents

There are many rivet manufacturers and suppliers in canada. So, do you know how to choose?

This blog lists top 8 blind rivet manufacturers and suplliers in canada, I believe it can help you.

Table of Contents

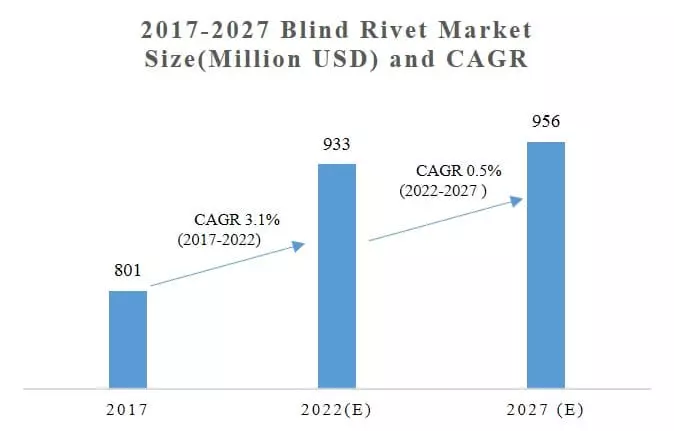

Benefits of Wholesale Blind Rivets from Manufacturers

Wholesale purchasing of blind rivets directly from rivet manufacturers offers multiple cost advantages, control and technical support advantages for the distributor, end manufacturer or project integrator.

1. Significant cost control

- Lower unit price: skip the distribution link and enjoy the factory price directly;

- Tiered Pricing Benefits: more competitive tiered pricing for volume purchases;

- Lower Total Cost of Purchase (TCO): reduce inventory turns and transportation surcharges;

- Support for customized packaging and labeling: save costs on dispensing, labor and labeling.

2. Higher consistency of technical specifications

- Direct connection to engineering team: can quickly confirm rivet structure, grip range, material combination, etc. based on drawings or samples;

- Customization capability: specific strength, waterproof, vibration or corrosion-resistant models can be developed to enhance the degree of matching;

- Standards consistency: more reliable than traders in delivering batch consistency in compliance with ISO, IFI, DIN, etc.

3. Engineering and application support

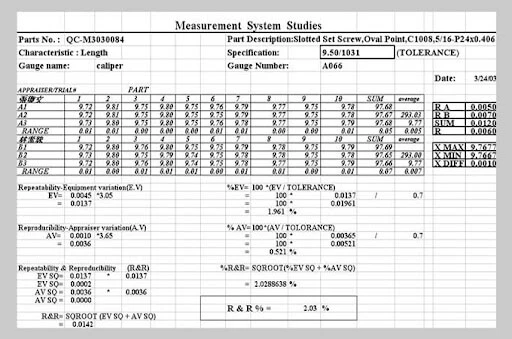

- Provide PPAP, COC, MSDS, REACH/RoHS and other compliance documents to help customers pass quality and environmental protection certification;

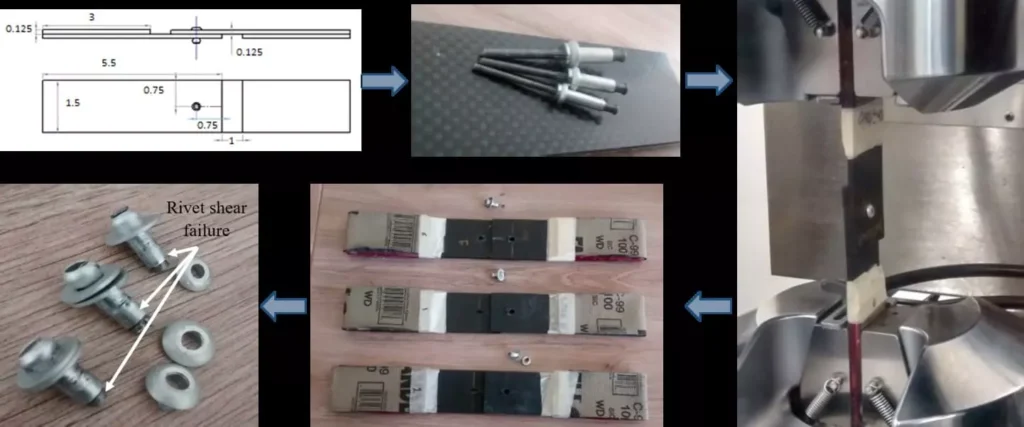

- Can cooperate to do on-site application testing (e.g. pull-shear experiment, failure analysis) to enhance project reliability;

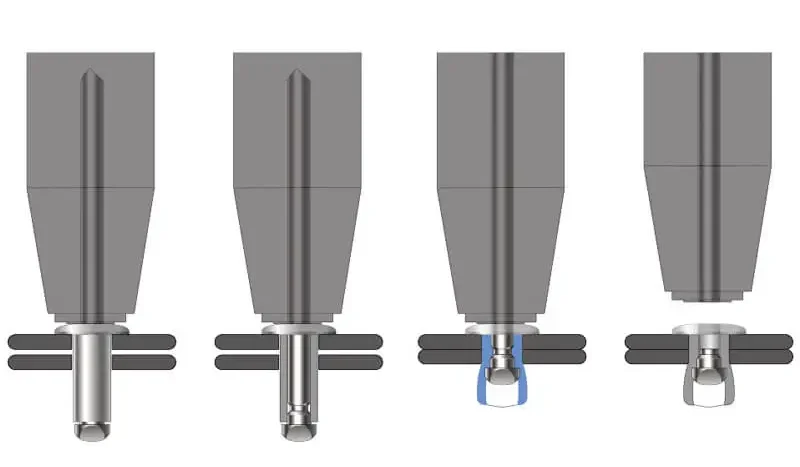

- Assist in the development of riveting process parameters, including hole size recommendations, tooling recommendations, installation pressure settings, etc..

4. Packaging and logistics flexibility

- Rivet manufacturers can customize industrial packaging (with barcode, logo, traceability code) according to customers’ needs.

- Support mixed specifications, small batch sub-packaging, easy for project-based shipment or parts package assembly.

- High logistic efficiency: production-boxing-direct shipping, shortening response cycle.

5. Brand controllability and market competitiveness

- Own brand operation (can be OEM/ODM): establish differentiated product lines to avoid pure price competition;

- Stable supply capability: transparency of manufacturer’s production capacity and delivery time, which is conducive to long-term contract planning.

Do You Have Any Questions?

Let Us Solve Your Problem

Top 8 Blind Rivet Manufacturers and Suppliers in Canada

| Rank | Company Name | Headquarters | Key Offerings |

| 1 | Rivmate Rivet | China | Blind rivets,Rivet Nuts,Structural Rivets,Self Piercing Rivets |

| 2 | Gesipa | Germany | Blind rivets, riveting tools |

| 3 | Stanley Engineered Fastening | USA | Blind rivets, structural fasteners |

| 4 | Infasco | Canada | Bolts, nuts, rivets |

| 5 | Hilti Canada | Liechtenstein | Rivets, power tools, construction systems |

| 6 | Bollhoff | Germany | Riveting and fastening systems |

| 7 | MacLean-Fogg | USA | Automotive & industrial fasteners |

| 8 | Rivefix | China | Rivet Nuts,Self Clinching Rivets,Riveting Tools. |

Ⅰ. Rivmate Rivet

Company Profile:

Rivmate is the world’s leading manufacturer and supplier of rivets.Rivmate provides low price and excellent quality rivets to many Canadian rivet distributors, so if you want to buy rivets in bulk, you can buy them wholesale directly from Rivmate.

Whether you are looking for standard blind rivets or high strength structural rivets, you will find a satisfactory solution at Rivmate, which has won the trust of a large number of Canadian customers with its high quality products and excellent customer service.

Main Products Series:

- Standard Blind Rivets

- Structural Blind Rivets

- Self Piercing Rivets

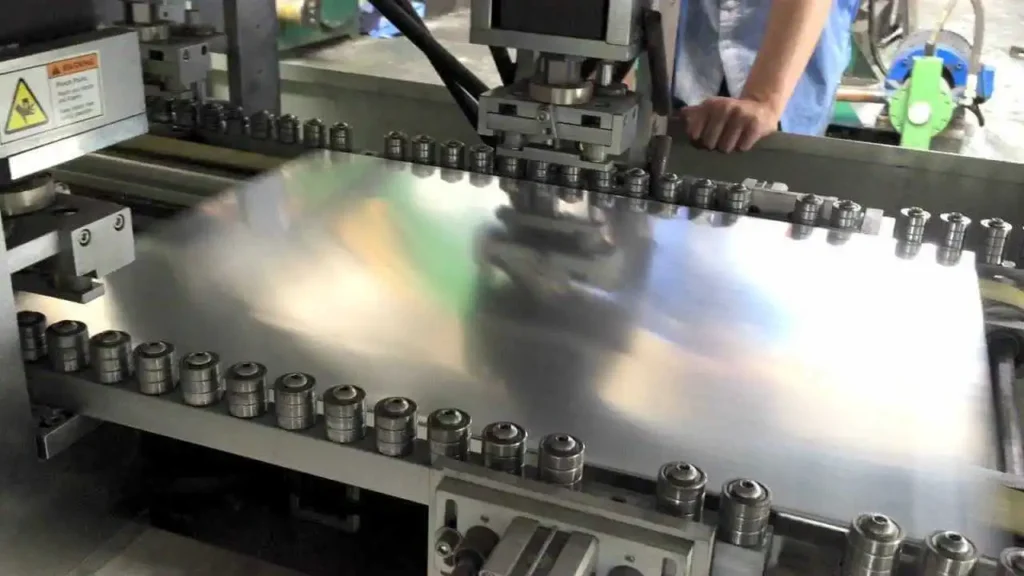

- Speed Riveting System

- Lockbolt Rivets System

- Rivet Nuts

- Riveting Tools

- Self Clinching Fasteners

Advantages of Rivmate:

- Over 20 years of experience in rivet production

- All rivet types can be supplied at once

- Extensive experience in international trade

Website: www.worldrivet.com

Ⅱ. Gesipa

Company Profile:GESIPA® is a leading blind rivet and riveting technology manufacturer headquartered in Germany and part of the Swiss SFS Group. Since its foundation in 1955, GESIPA® has specialized in providing high-quality rivets, riveting tools and automation solutions to industrial customers worldwide. Its products are used in a wide range of applications in automotive, transportation, construction, industrial equipment and automated assembly.GESIPA® holds a strong position in the Canadian blind rivet market due to its high quality products, innovative technology and strong customer support. This includes high-strength rivets and automated riveting solutions for Canadian automotive manufacturers. Diversified riveting solutions for manufacturers of machinery and equipment, appliances and electronics. In addition, GESIPA® ensures the availability of its products in the Canadian market and after-sales support by working with local distributors.

Advantages of GESIPA:

- Technological Innovation: Continuous investment in R&D to introduce new products and solutions that meet market needs.

- Quality Control: All products are manufactured in Germany to ensure high standards of quality and consistency.

- Customized service: Ability to provide products and services tailored to specific customer needs.

- Global Support Network: Provides timely technical support and after-sales service through our global branches and partners.

Core product and technology strengths:

- Blind Rivet Collection

- Riveting Tools

- Automated Riveting System

Website:https://en.gesipa.de/

Ⅲ. Stanley Engineered fastening

Company Profile:Stanley Engineered Fastening is based in Maryland, USA. With more than 100 years of manufacturing history and facilities and technical centers in more than 30 countries, Stanley Engineered Fastening is the world’s leading manufacturer of fasteners and assembly systems, from standard rivets to high-end structural joining systems for the automotive, aerospace, construction, electronics, rail transportation and industrial manufacturing industries. The company is a leading manufacturer of fasteners and assembly systems.

As a world-renowned brand, Stanley Engineered Fastening has a distribution and technical support center in Canada. Stanley Engineered Fastening is primarily involved in automotive manufacturing, infrastructure and railroad projects, and metal fabrication and mechanical assembly.

Advantages of Stanley Engineered fastening:

- Fast delivery of locally stocked models (POP general purpose / Avdel structural)

- Technical selection advice, installation training, quality documentation (PPAP, COC) are available.

- OEM project support for customized rivet structure/logo/packaging

Core product and technology strengths:

- POP® Rivets

- Avdel® Structural Rivets

- Huck® Lockbolt Systems

- Riveting Tools and Automation Systems

Ⅳ. infasco

Company Profile:Infasco is a leading Canadian manufacturer of fasteners, part of the Heico Companies, founded in 1958 and headquartered in Marieville, Quebec.The company has a significant presence in the North American market, particularly in Canada, with its vertically integrated production system and broad product portfolio. The company has a significant presence in the North American market, particularly in Canada, with its vertically integrated production system and broad product portfolio.

In Canada, Infasco provides reliable riveting and fastening solutions to the automotive, construction and infrastructure, and energy industries. In addition, the company operates several distribution centers in Canada, including Edmonton, Alberta, and Winnipeg, Manitoba.Infasco works with a number of distributors, including Gould Fasteners, to ensure wide availability and timely delivery of its products in the Canadian market. In addition, the company offers custom ordering services to meet specific customer needs.

Quality Certification:

ISO 9001

IATF 16949

ISO 17025

ISO 14001

ISO 45001

Core product and technology strengths:

- Rivets

- Screws

- Bolts

- Nuts

Website:https://infasco.com/en/

Ⅴ. hilti canada

Company Profile: Hilti Canada is a globally recognized supplier of architectural and industrial fastening solutions. Its riveting business in the Canadian market focuses on efficient, portable power riveting tools specifically suited for metal curtain wall installation, sheet metal fabrication, HVAC systems, railings and transportation equipment manufacturing.Hilti’s riveting business in Canada is targeted at the mid-to-high end of the market and serves a wide range of customers, including specialty contractors, industrial manufacturers and large-scale projects.Hilti’s products are recognized for their high quality, innovation and reliability in the Canadian market, Hilti’s products have earned a reputation for quality, innovation and reliability in the Canadian market.

Advantages of hilti canada:

- Efficient: Motorized cordless design improves work efficiency, especially for projects that require quick installation

- Portability: Cordless design makes the tool more portable and suitable for various construction environments.

- Versatility: Compatible with a wide range of materials and sizes of rivets to meet different project requirements.

- After-sales service: Hilti offers comprehensive after-sales support, including tool repair and replacement services.

Core product and technology strengths:

RT 6-22 Cordless Rivet Gun

RT 6-22 Replacement Rivet Nozzle Set

Website:https://www.hilti.ca/

Ⅵ. bollhoff

Company Profile:Böllhoff, a family-owned company headquartered in Germany, has specialized in fastening technology since 1877 and has grown to become one of the world’s leading suppliers of joining solutions. In Canada, Böllhoff operates from a sales office in Whitby, Ontario, offering a diverse range of riveting products and technical support, serving a wide range of sectors including automotive, construction, electronics and industrial manufacturing.

In Canada, Böllhoff offers technical consulting and project support, customized fastening solutions and product training and after-sales service. Its products are widely used in automotive manufacturing, construction and infrastructure, electronics and appliances and industrial manufacturing.

Advantages of Bollhoff:

- Böllhoff has a strong R&D department that continues to drive innovation in materials, processes and assembly automation.

- We provide a complete service chain from design support and testing to assembly tools and automation systems, emphasizing “complete solutions from product to process”.

- All production sites (mainly in Germany and France) implement strict quality control systems to meet ISO/TS and industry-specific standards (e.g. VDA, EN).

Core product and technology strengths:

- RIVNUT® Blind Rivet Nuts

- RIVSTUD® Blind Rivet Studs

- RIVQUICK® Blind Rivet

- RIVSET® Self-Pierce Riveting System

Website:https://www.boellhoff.com/us-en/

Ⅶ. maclean fogg

Company Profile:MacLean-Fogg is a U.S.-based, family-owned company founded in 1925 that specializes in engineering solutions for a variety of industries, including automotive, industrial and materials handling. With five business segments – Fastener Solutions, Engineered Solutions, Plastic Solutions, Additive Manufacturing Solutions and Mallard Manufacturing – MacLean-Fogg is well positioned to serve its customers with multiple manufacturing and distribution facilities throughout North America.

Advantages of Bollhoff:

- Offers a wide range of engineered fasteners, precision machined parts, and heat-treated products, especially for critical applications in the automotive and heavy-duty truck industries.

- Has manufacturing facilities and distribution centers throughout the U.S., Mexico, and Canada.

- Strong Engineering and Joint Development Capabilities

- Focus on quality and customer service, consistently maintain quality certifications such as ISO/IATF, popular with OEMs.

- Emerging areas such as sustainable technologies (green manufacturing and recycled materials).

Website:https://macleanfogg.com/

Ⅷ. rivetfix

Company Profile: Rivetfix has over 15 years of experience in the production of rivet nuts. Compared to bollof and sherex, Rivetfix rivet nuts are very inexpensive and of similar quality. So if you want to buy high quality rivet nuts for your business, there is no doubt that Rivetfix is the right choice.

Main Products:

- Rivet Nuts

- Blind Rivet Nuts

- Jack Nuts

- Riveting Tools

- Self Clinching Fastener

- Drill Bits

Website:www.rivetfix.com

Do You Have Any Questions?

Let Us Solve Your Problem

Why Choose Rivmate as Your Rivet Manufacturer?

Bypass the middleman and buy rivets directly from the rivet manufacturer. You get more consistent rivet quality and price. This is the biggest benefit of buying directly from the rivet factory.

In addition to this, if you have customization needs, Rivmate can also provide it for you. Get rivet samples for testing today!

Get Rivets Quote

Buy Open Type Blind Rivets

Buy Structural Blind Rivets