Home » 归档于 eric@world-rivet.com » 第11页

Blind Rivets Size Guide

Rivmate Fastener

Top Rivet and Rivet Nut Manufacturer in China

Table of Contents

Blind rivet size consists of many parts. Do you know which rivet parameter you should focus on? Read this Blind rivets size guide together.

Table of Contents

Blind Rivet Size Composition

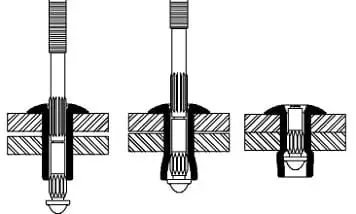

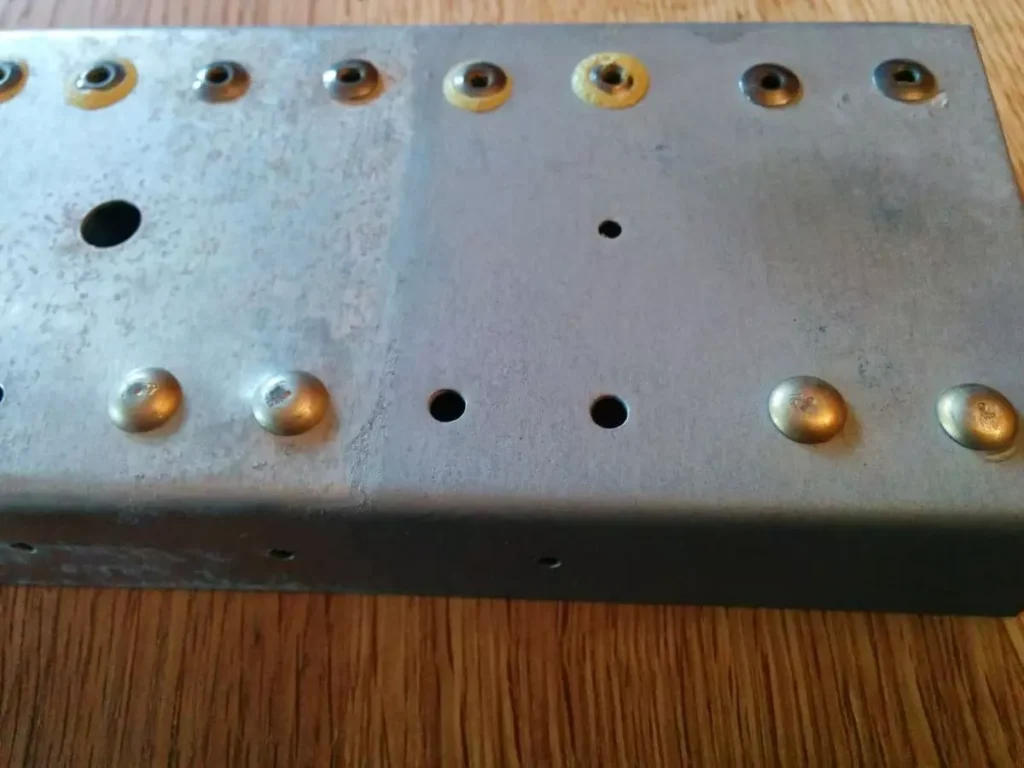

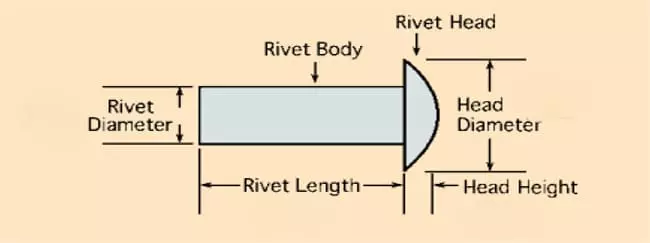

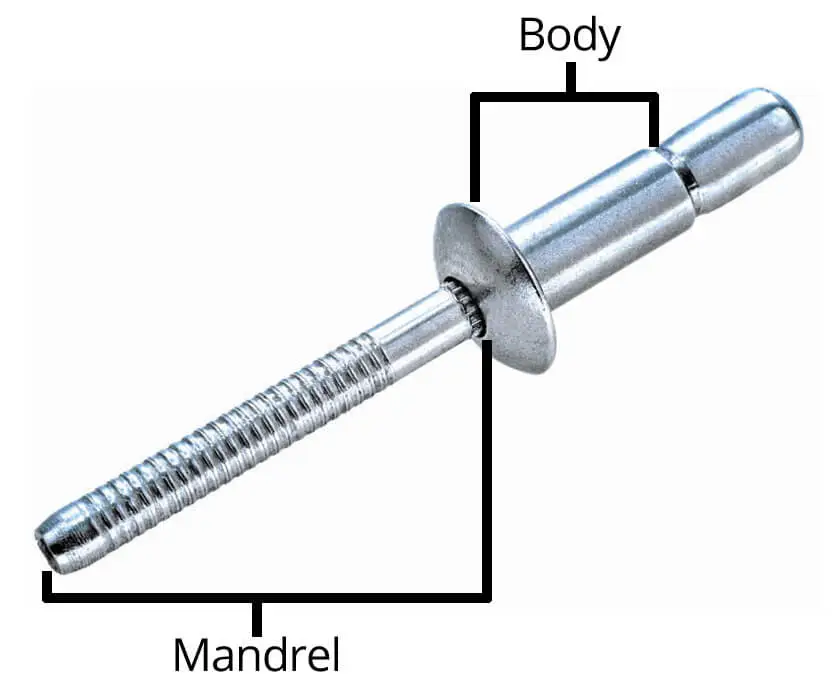

Before you buy a blind rivet, you need to understand exactly how the specifications of a blind rivet are composed. This way, you can provide your rivet supplier with the complete purchasing requirements. This will save a lot of communication costs. The specification of a complete blind rivet consists of the following parts:

Rivet diameter is the body diameter of a rivet and is commonly used to indicate the size of a rivet. It is a key factor in rivet selection, joint strength and application.

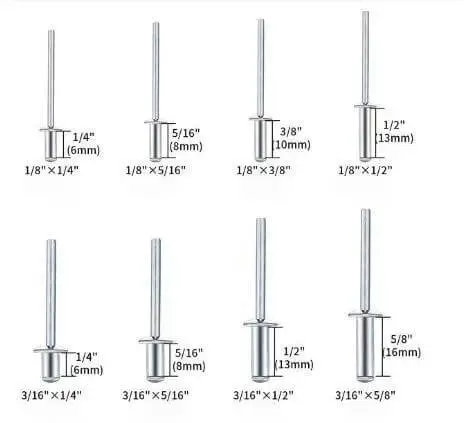

Rivet diameters are usually standardized and marked in inches or millimeters. Common rivet diameters include:

- 2.4 mm (3/32″)

- 3.2 mm (1/8″)

- 4.0 mm (5/32″)

- 4.8 mm (3/16″)

- 6.4 mm (1/4″)

- 8.0 mm (5/16″)

- …….

Application Scenarios for Different Blind Rivet Diameters

According to the different rivet diameters, rivets are used in different application scenarios:

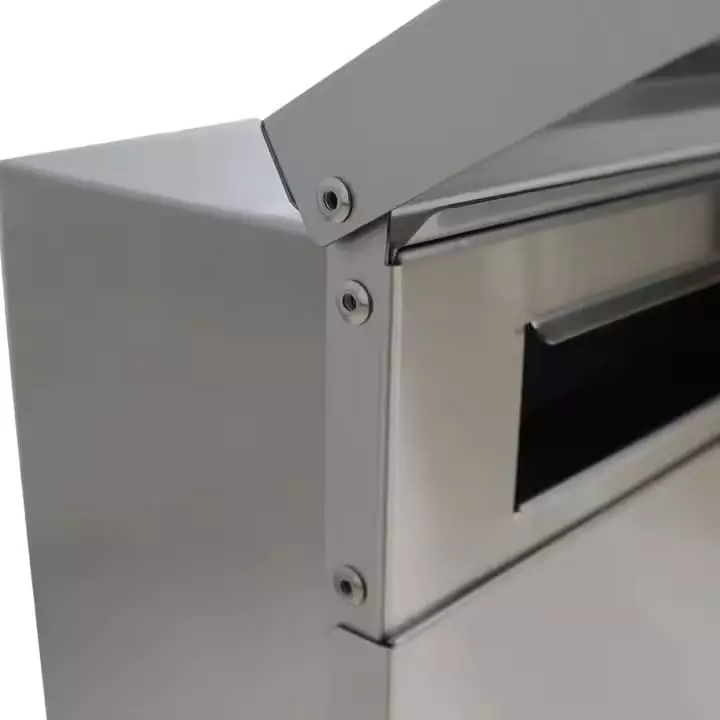

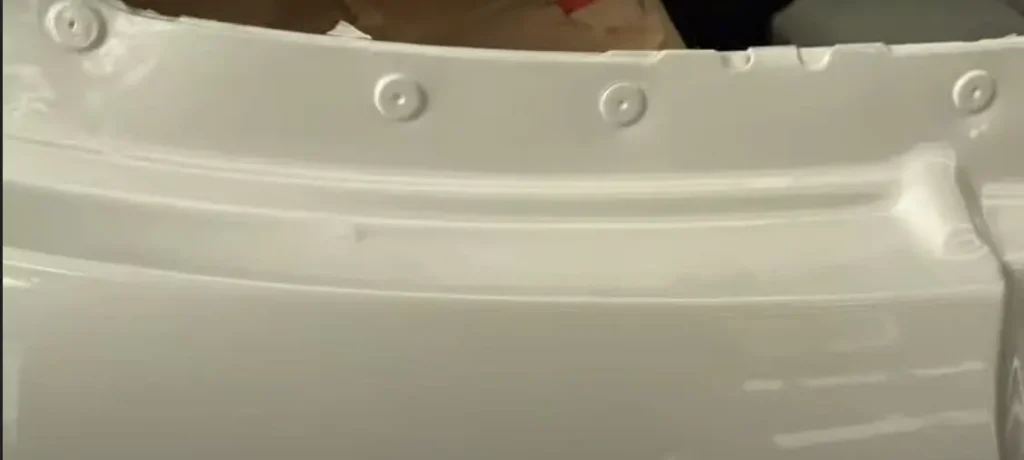

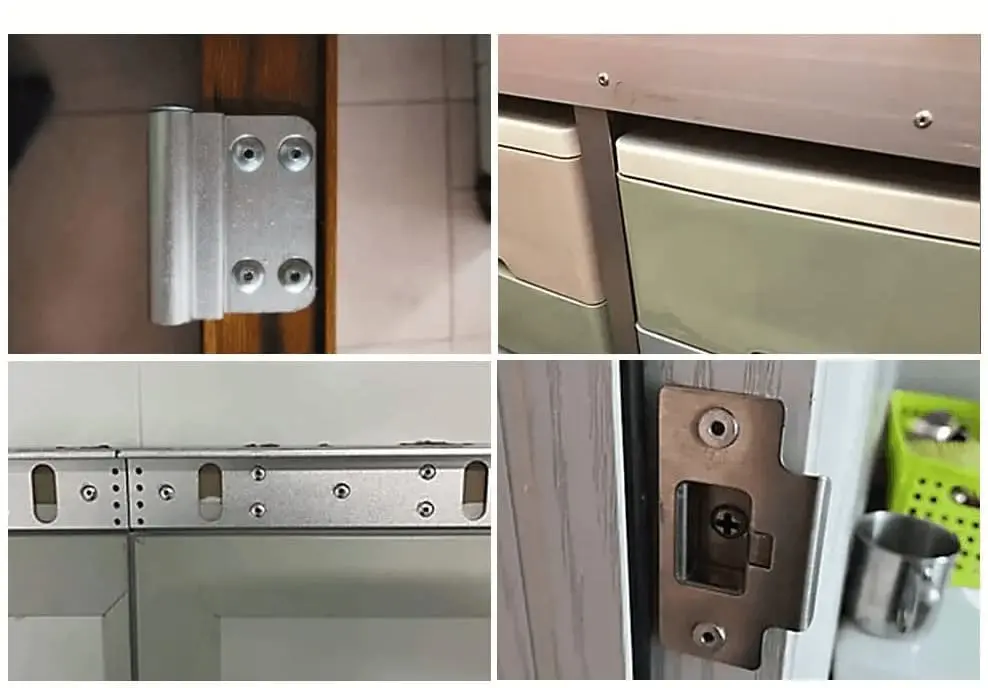

- Small diameter rivets (2.4 mm, 3.2 mm): commonly used in light duty applications, such as electronics, home appliances, and decorative items.

- Medium diameter rivets (4.0 mm, 4.8 mm): commonly used in medium load applications, such as automotive components, light mechanical equipment and thin steel plates.

- Large Diameter Rivets (6.4 mm, 8.0 mm): for high strength industrial applications such as aerospace, shipbuilding, heavy equipment and building structures.

Do You Have Any Questions?

Let Us Solve Your Problem

Rivet Body Length

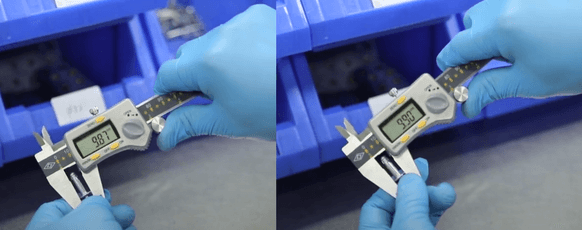

Blind Rivet Body Length is the length of the rivet body portion of a blind rivet, i.e., the length from the head to the bottom of the rivet. The choice of rivet length directly affects the strength of the riveted joint, the stability of the installation and the final result.

Typically, the length of a rivet does not include the head of the rivet and the extension of the tail of the rivet. The total length of a rivet is usually measured by the outside measurement of the rivet, including the head.

The Role of Blind Rivet Body Length

Rivet length is a key factor in determining the strength and suitability of a rivet joint. Selecting the proper body length ensures that the rivet will completely penetrate the material to be joined, providing a strong connection. The right rivet length helps:

- Increase joint strength: If the rivet is of the right length, it will be able to press sufficiently against the surface of the material to ensure a tight joint.

- Ensure a stable riveted joint: A rivet of the right length ensures that the rivet is fully secured and provides adequate support during riveting.

- Avoid damaging the material: rivets that are too long can lead to material damage during riveting or excessive compression of the head of the rivet, resulting in an unstable connection; while rivets that are too short may not fully penetrate the material, resulting in a loose connection.

Application scenarios for different rivet lengths:

Short length rivets: suitable for the connection of thinner materials. Such as thin steel, plastic or light aluminum alloy plate.

Long length rivets: suitable for multi-layer materials, thick plates or connections with greater strength requirements. Such as heavy machinery, building structures or aerospace.

Head Diameter

The Rivet Head Diameter (RHD) of a Blind Rivet is the maximum outside diameter of the head of the rivet. Generally, it is larger than the diameter of the rivet body. This dimension is an important indicator for evaluating the suitability of a rivet and directly affects the installation process and fixing strength of the rivet.

Standard sizes and common types of rivet head diameter

Rivet head diameter size is usually categorized based on rivet specifications and standards, common standards include:

- American Standard (ANSI): According to the U.S. standard for rivets, the rivet head diameter is usually 1.5 to 2 times the outside diameter of the rivet. For example, a common rivet OD is 4.0mm, then the head diameter may be between 6.0mm and 8.0mm.

- European Standard (DIN): The European standard rivet head diameter is also adjusted to the outside diameter of the rivet, but may vary in specific dimensions.

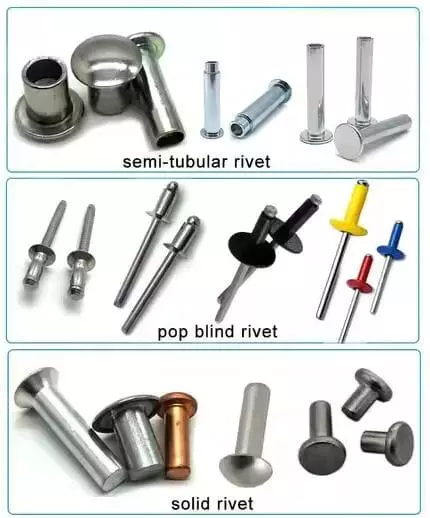

There are usually several common types of rivet heads, for example:

- Round Head Rivet (Domed Head): the most common type with a smooth hemispherical top.

- Flat Head Pop Rivets: Flat top for applications where flat surface contact is required.

- Countersunk Head Blind Rivets: Used where a flush surface contact is required, with a tapered head.

Grip Range

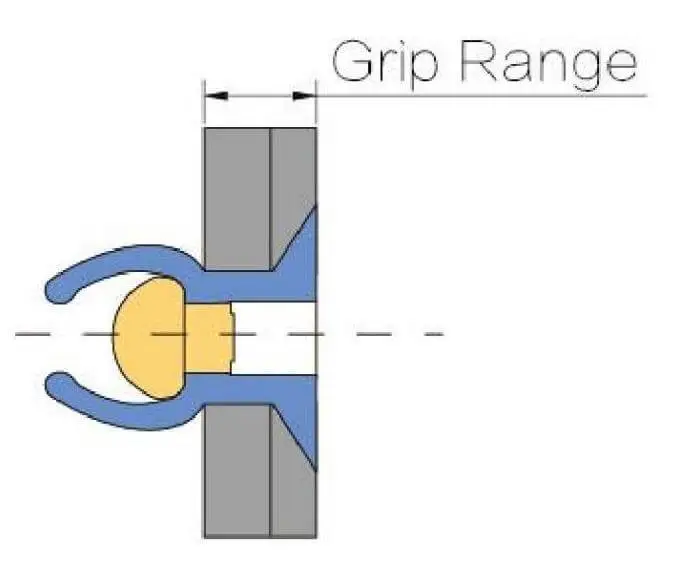

Grip Range is the maximum range of thickness of material that a blind rivet can hold. The correct Grip Range ensures that the rivet will securely hold two or more layers of material together and that the riveting process is robust and stable.

Selecting the proper grip range is critical to the effectiveness of the riveted joint. Too small or too large a grip can result in a riveted joint that is not strong enough or difficult to install.

Grip range is the range of thicknesses of material that a rivet can compress and hold. It usually has a minimum and a maximum value, i.e. the minimum material thickness and the maximum material thickness that the rivet can accommodate. Example:

- Minimum Grip Range: The thinnest material thickness that a rivet can hold.

- Maximum Grip Range: The thickest material thickness that the rivet can hold down.

When installing rivets, the thickness of the material to be joined must fall within this range. This ensures that the head of the rivet will hold the material securely and that the body of the rivet will properly penetrate through the material and form a strong connection.

Blind Rivet Grip Range Size Chart

The grip range of a rivet is usually related to the diameter and length of the rivet. Common grip ranges, based on standard dimensions, are as follows:

| Rivet Diameter (mm) | Grip Range (mm) |

| 3.2 (1/8″) | 0.8 – 3.0 |

| 4.0 (5/32″) | 1.5 – 5.0 |

| 4.8 (3/16″) | 2.0 – 7.0 |

| 6.4 (1/4″) | 3.0 – 9.5 |

| 8.0 (5/16″) | 4.0 – 13.0 |

Proper selection of the Blind Rivet Grip Range is a critical step in ensuring the quality of the riveted joint. It determines the range of material thicknesses that can be effectively fixed by the rivet, ensuring robustness and stability during the riveting process. When choosing pop rivets, it is important to consider the thickness of the material, the type of material, the application scenario and the required fixing strength to ensure that the grip range of the rivet selected meets the actual requirements.

Do You Have Any Questions?

Let Us Solve Your Problem

What Happens When Blind Rivets is the Wrong Size?

Using the wrong size blind rivet can lead to a number of undesirable consequences. These consequences not only affect the quality of the connection, but can also result in safety hazards, increased costs and reduced productivity. The following are some of the main consequences of using the wrong size Blind Rivet:

1. Poorly Riveted Joints

- Rivets that are too small: If a rivet is too small (not large enough in diameter or length), it will not be able to adequately penetrate and secure the thickness of the material. In this case, the riveted connection may loosen, resulting in a weak connection that cannot withstand stress or external loads.

- Oversized rivets: If a rivet is too large, it may put too much pressure on the material, resulting in cracking or deformation.

2. Incorrect Grip Range

- Grip range too small: If the grip range of the selected rivet is insufficient, it may not cover all the thickness of the material to be joined. The rivet will not fully grip the material, resulting in a poorly riveted joint.

- Grip range too large: A rivet with a grip range that is too large can result in the rivet being pressed into the material at too shallow a depth. This reduces the stability of the connection and may even lead to elastic failure of the rivet.

3. Installation Difficulties

- Installation Difficulty: Improperly sized rivets may make the installation process more difficult. If the rivet is too long or too short, it may result in the riveting tool not being able to effectively apply enough pressure or in some cases not even be able to fully install the rivet.

- Tool Wear: Wrong size rivets can put undue pressure on the installation tool, causing wear or damage to the tool and increasing repair costs.

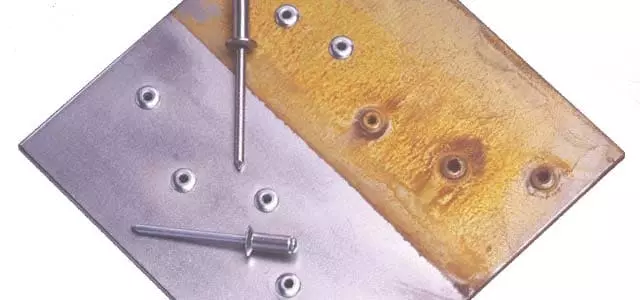

4. Material Damage

When too large or too small a rivet is used, the head of the rivet may exert an uneven force, causing deformation or damage to the material. For thin sheet metal materials, oversized rivets may create excessive localized pressures that can deform or crack the material.

5. Safety Hazards

- Structural failure: In some applications with high strength requirements, the use of inappropriately sized rivets can lead to loosening, fracture or disintegration of the connected parts. This poses a safety risk, especially in industries such as aerospace, automotive or construction.

- Reduced durability: Incorrectly sized rivets can lead to reduced durability and possible failure of the connection when subjected to repetitive loads, vibration or extreme environmental conditions.

Wholesale Blind Rivets from Manufacturer

By reading this article, I am sure you have got a detailed understanding of blind rivets size guide. If you would like a customized riveting solution for your project, please contact our engineers.

Whether you need blind rivets or structural rivets, Rivmate has you covered.

Get rivet samples now!